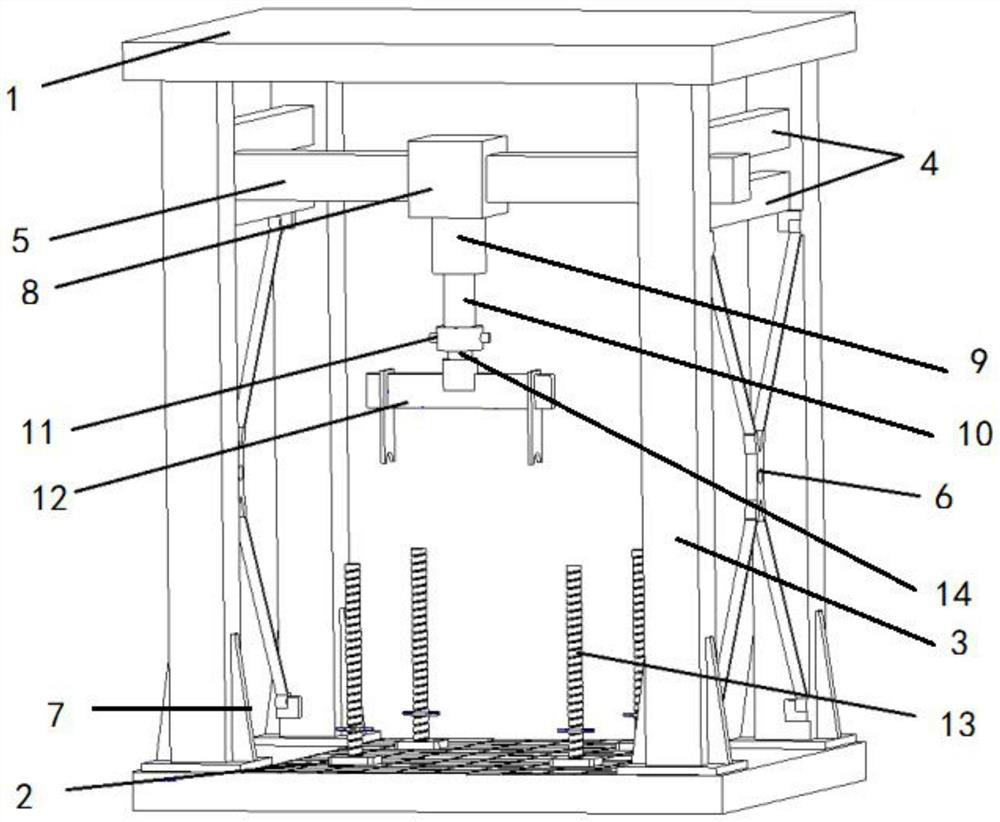

Multifunctional detection device for disc buckle type steel pipe support component and use method of multifunctional detection device

A steel pipe support and detection device technology, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, etc., can solve the detection process Troubleshooting, complicated fixtures, long assembly time and other problems, to achieve the effect of simplifying the testing fixture, strong comprehensive testing ability, and shortening the testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Unilateral shear detection

[0038] Depend on figure 2 As shown in Fig. 1, the threaded support and the one-sided shear pressure member are selected and assembled. The workpiece to be tested is fixed on the threaded support, and the corresponding position of the cross bar is adjusted through the motor drive. The loading system is controlled by a microcomputer and the oil cylinder is stable. , apply a specified load on the crossbar and keep the load for 2 minutes. After the single test is completed, the position can be adjusted to other crossbars to apply pressure to complete the unilateral shear strength test of the connection plate.

Embodiment 2

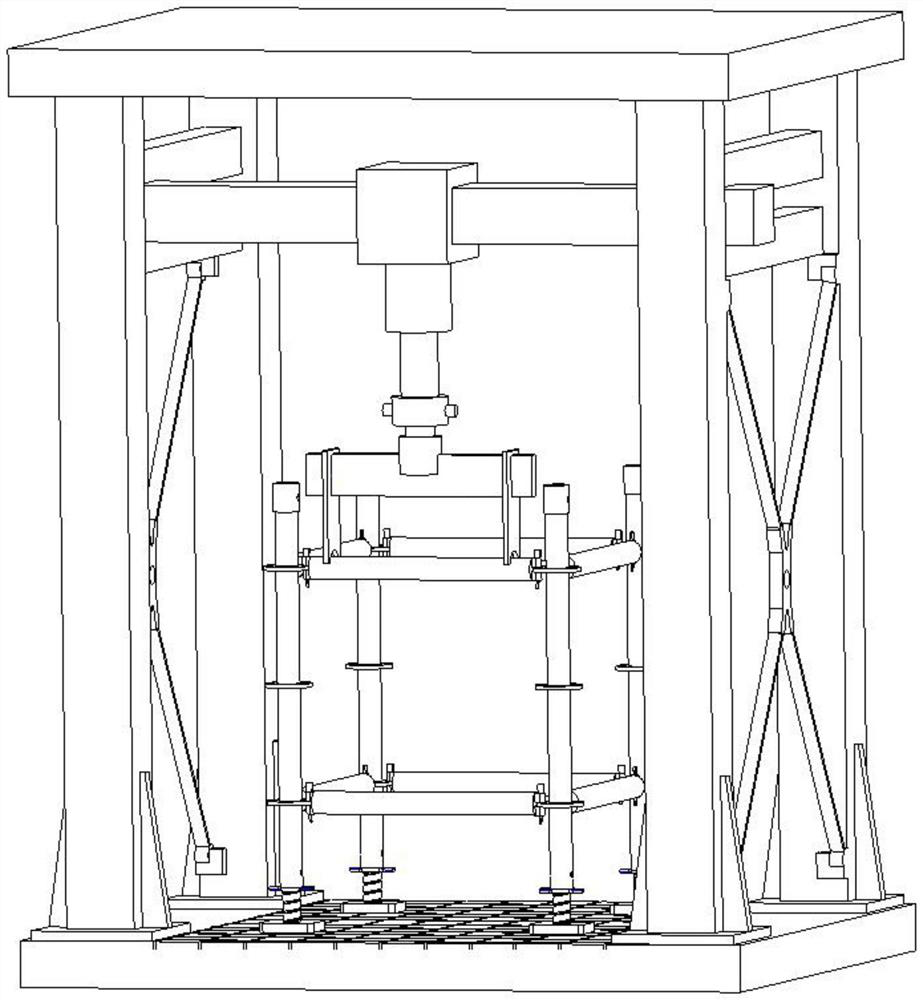

[0039] Example 2 Bilateral shear detection

[0040] Depend on image 3 As shown, the threaded support and the double-sided shear pressure parts are selected and assembled, the workpiece to be tested is fixed on the threaded support, and the corresponding position of the crossbar is adjusted through the motor drive, and the loading system is controlled by the microcomputer and the oil cylinder stabilizes the output. , apply a specified load to the crossbar and keep the load for 2 minutes. After the single test is completed, the position can be adjusted to other crossbars to apply pressure in order to complete the double-sided shear strength test of the connecting plate.

Embodiment 3

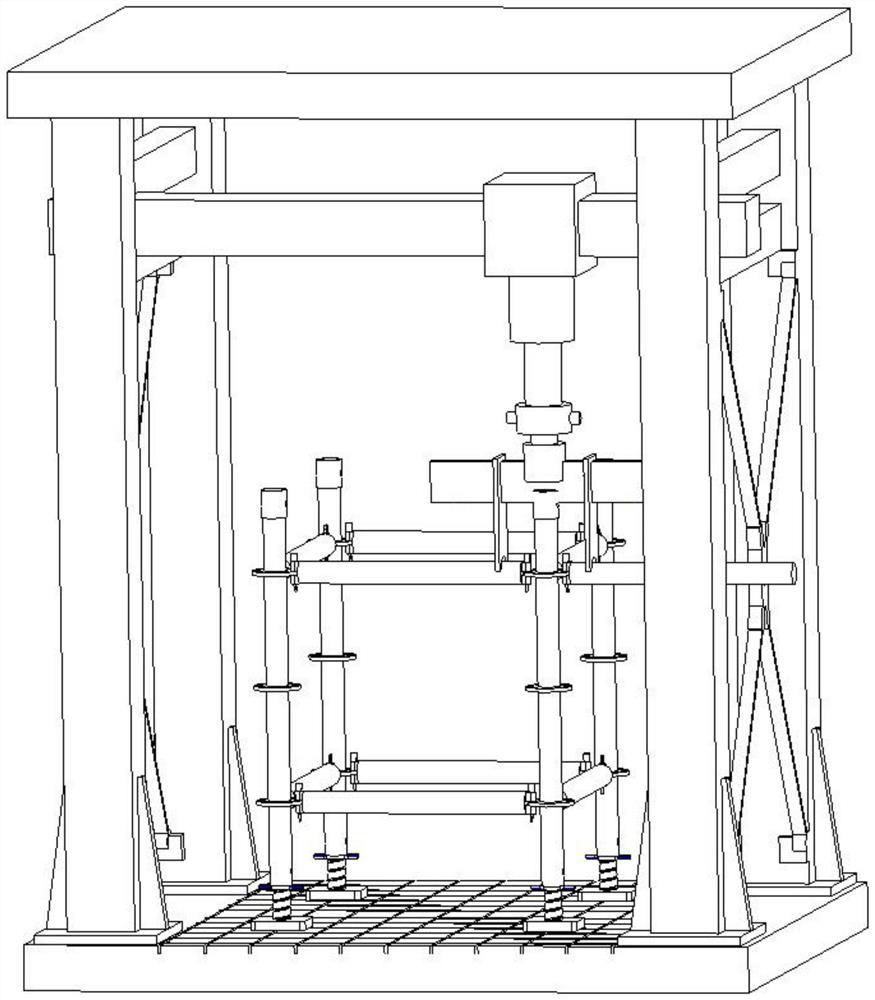

[0041] Example 3 Detection of the Shear Strength of the Girth Weld of the Connection Plate

[0042] Depend on Figure 4 As shown in Fig. 1, the threaded support and the shear pressure parts of the connecting plate ring weld are selected and assembled. The workpiece to be tested is fixed on the threaded support, and the corresponding position of the cross bar is adjusted through the motor drive. To output the load strength, apply a specified load to the crossbar and keep the load for 2 minutes. After the single test is completed, the position can be adjusted to other crossbars to apply pressure to complete the shear strength test of the ring weld of the connecting plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com