Radial flexible structure of scroll compressor and scroll compressor

A scroll compressor and flexible structure technology, applied in the field of scroll compressors, can solve the problems of non-adjustable spindle eccentricity, poor adaptability, and large noise of scroll compressors, so as to eliminate abnormal noise, reduce precision fluctuations, and avoid impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

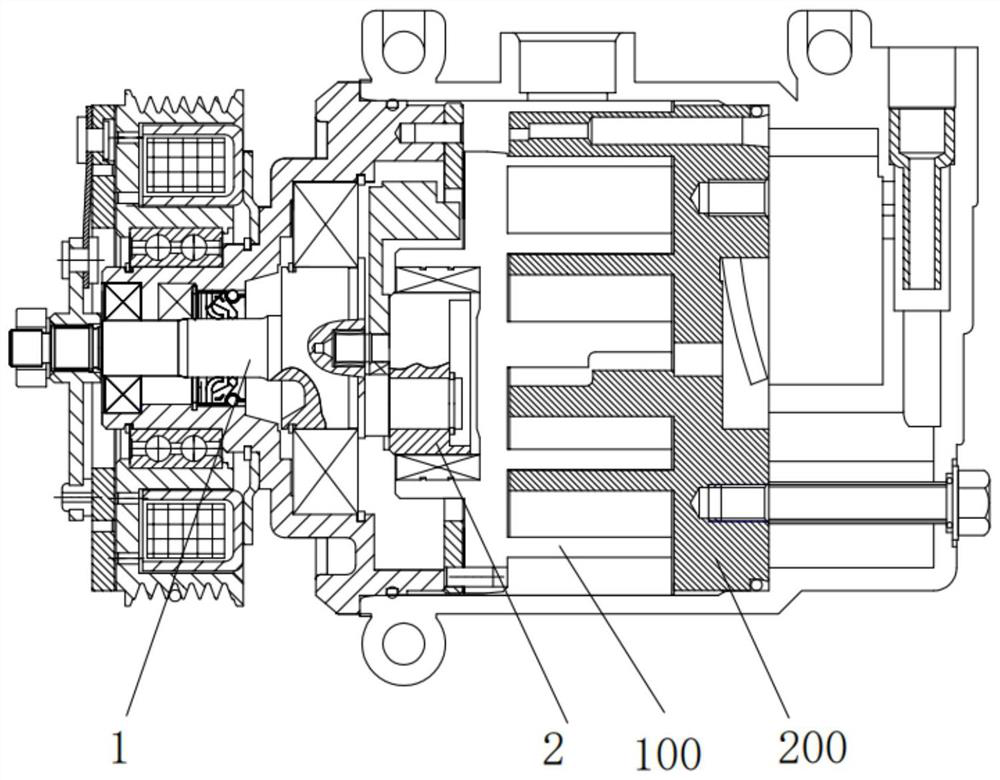

[0031] Such as figure 1 As shown, the scroll compressor is a volumetric compression compressor, and the compression components are composed of a movable scroll 100 and a fixed scroll 200 . The main shaft 1 drives the movable scroll 100 to move through the eccentric sleeve 2. The eccentricity of the main shaft 1 of the existing scroll compressor cannot be adjusted, which makes the adaptability of the scroll compressor to different speeds and loads poor, and the There is a collision between the main shaft pin hole and the adjustment pin 21 on the eccentric sleeve 2, which makes the scroll compressor produce abnormal noise and relatively loud noise when it is started or stopped.

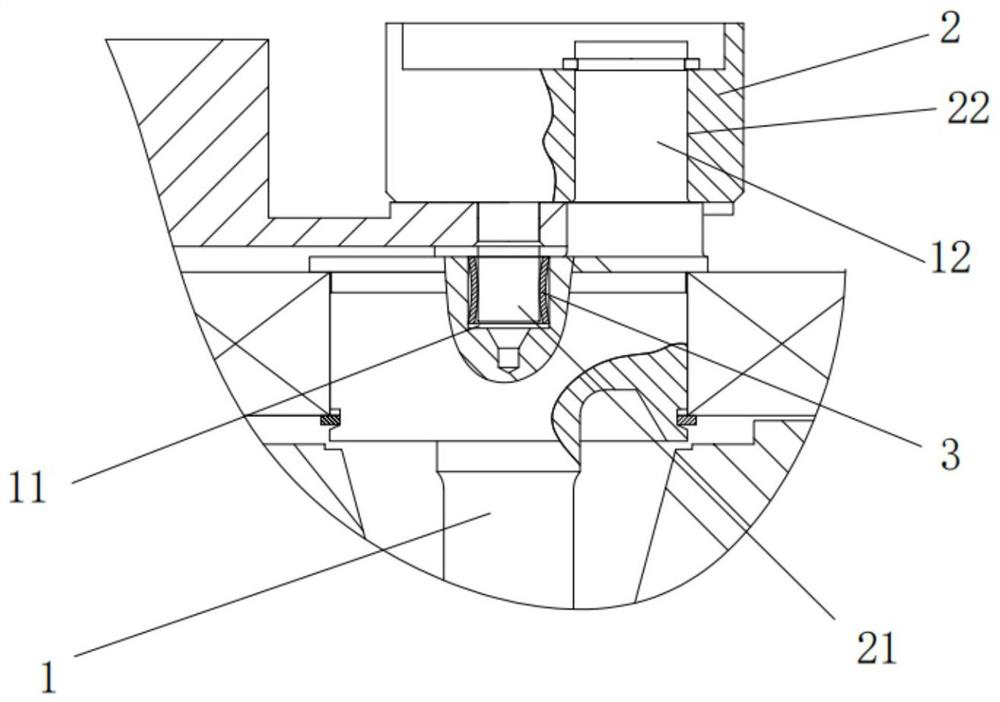

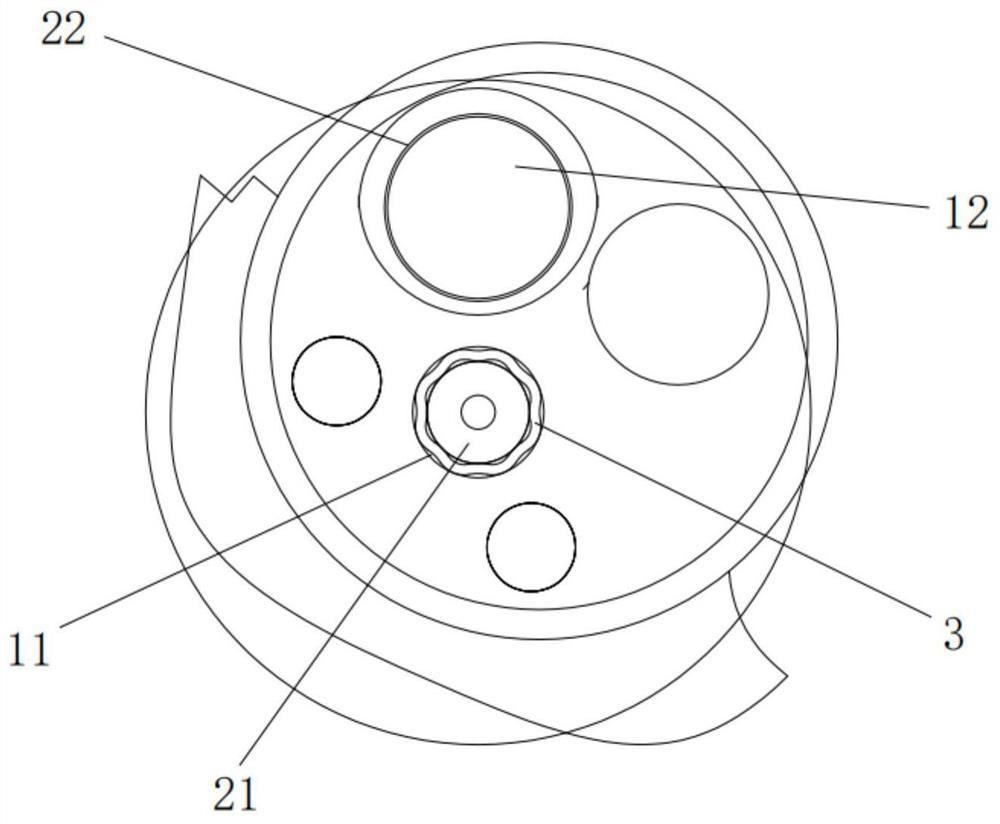

[0032] Such as Figure 2-Figure 3 As shown, this embodiment provides a radially flexible structure of a scroll compressor, including a main shaft 1 and an eccentric sleeve 2, the main shaft 1 is provided with a main shaft pin hole 11, the eccentric sleeve 2 is provided with an adjustment pin 21, and th...

Embodiment 2

[0038] Such as Figure 5 As shown, the radially flexible structure of the scroll compressor provided by this embodiment is roughly the same as that of Embodiment 1, the difference is that the outer peripheral wall of the transverse section of the adjustment sleeve 3 is in a C-shaped broken shape, and after the installation is completed , the C-shaped break-shaped slit is closed, and the outer peripheral wall of the transverse section is a complete circle after closing. Further, in this embodiment, the distances between the opposite peripheral walls of the longitudinal section of the adjustment sleeve 3 are equal.

[0039] It should be noted that in Embodiment 1 and Embodiment 2, the specific shape of the outer peripheral wall of the transverse section of the adjustment sleeve 3, whether the outer peripheral wall of the transverse section is closed, and the specific shape of the outer peripheral wall of the longitudinal section of the sleeve 3 can be combined arbitrarily. For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com