Eccentric gear turning rotary platform

A gear turning and turning table technology, applied in turning equipment, tool holder accessories, metal processing equipment, etc., can solve the problems of inability to move greatly, hidden dangers, repairs, etc., and improve work efficiency and safety factor. High, easy to debug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

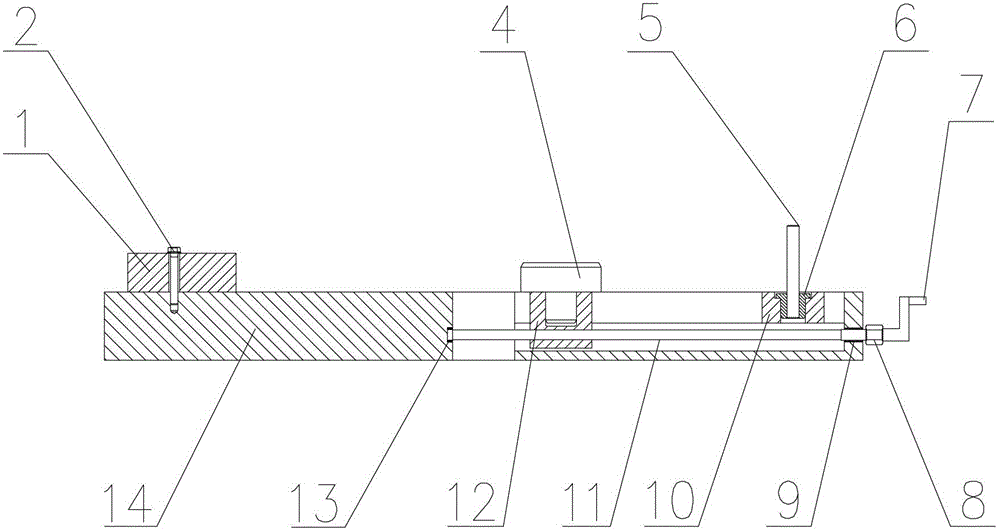

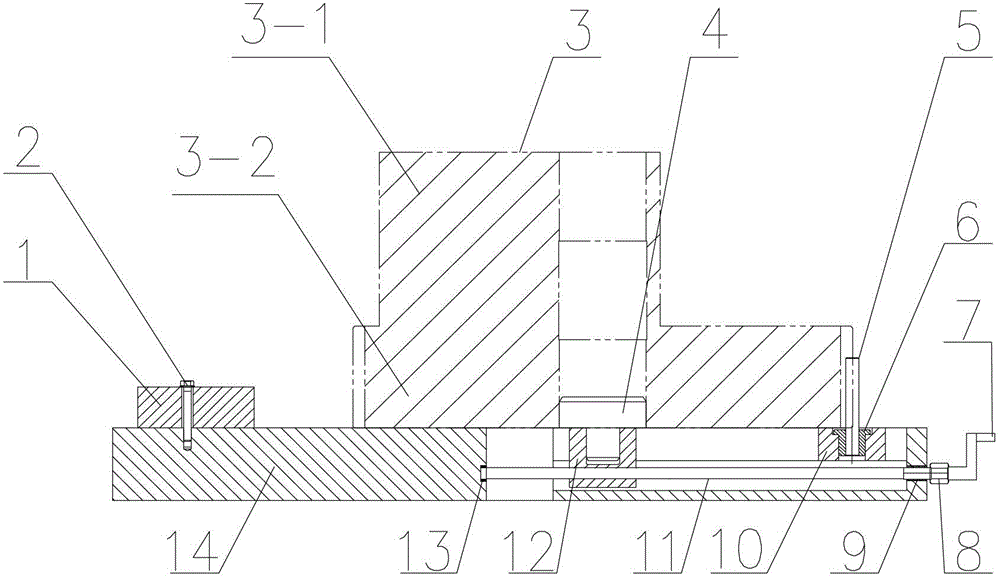

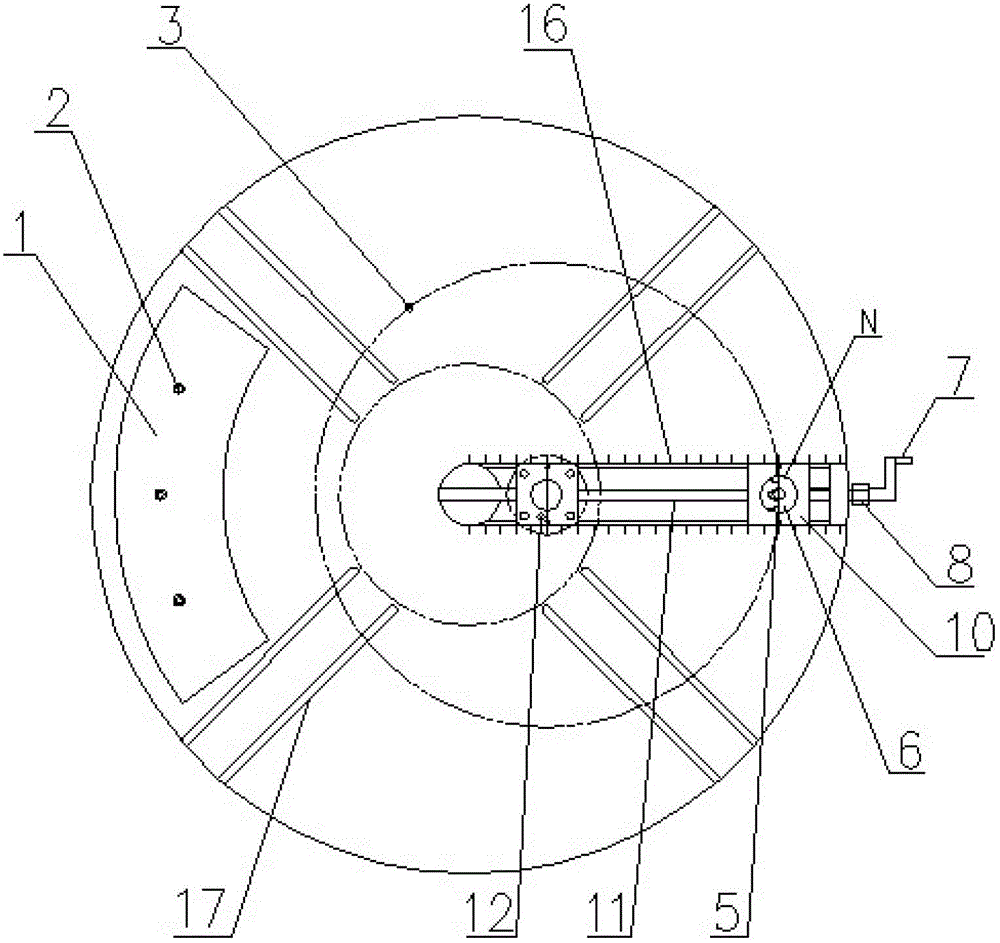

[0014] Such as figure 1 As shown, the eccentric gear turning table includes a circular chassis 14, a U-shaped groove guide rail is arranged in the radial direction of the circular chassis 14, and a center indicator line is marked on the circular chassis 14, and a lead screw 11 is worn in the middle of the U-shaped groove guide rail. , the inner end and the outer end of the screw 11 are respectively supported in the U-shaped groove guide rail by the bearing 13 and the copper sleeve 9, and a threaded pointer slider 12 is worn on the screw 11, and the pointer slider 12 is engraved with a pointer, A mandrel 4 is inlaid in the pointer slider 12, the handle 7 is connected with the lead screw 11 through a nut 8, and a floating slider 10 is also arranged in the U-shaped groove guide rail of the round chassis 14, and the floating slider 10 is inlaid with a There is a positioning sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com