Front upward sliding type charging port cover movement mechanism

A technology of motion mechanism and charging port, applied in the field of auto parts, can solve the problems of leakage of hinge structure, uncomfortable switching force, easy entry of dust, etc., to achieve smooth opening and closing, avoid labor intensity, and have little effect on appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

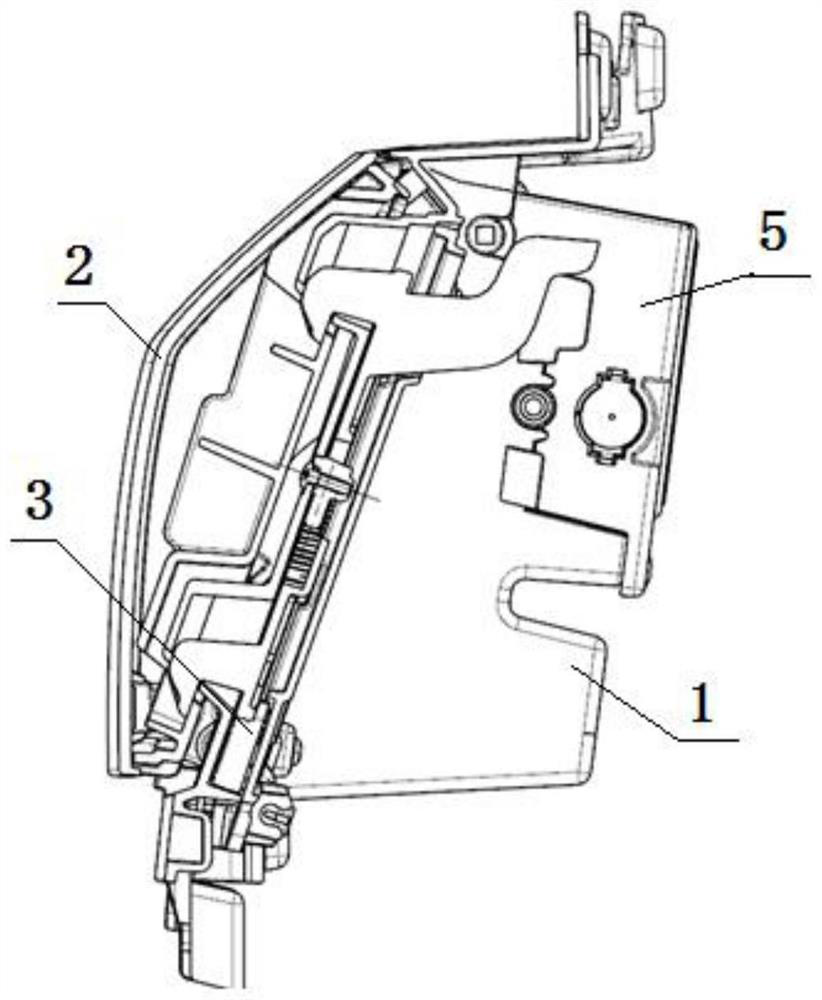

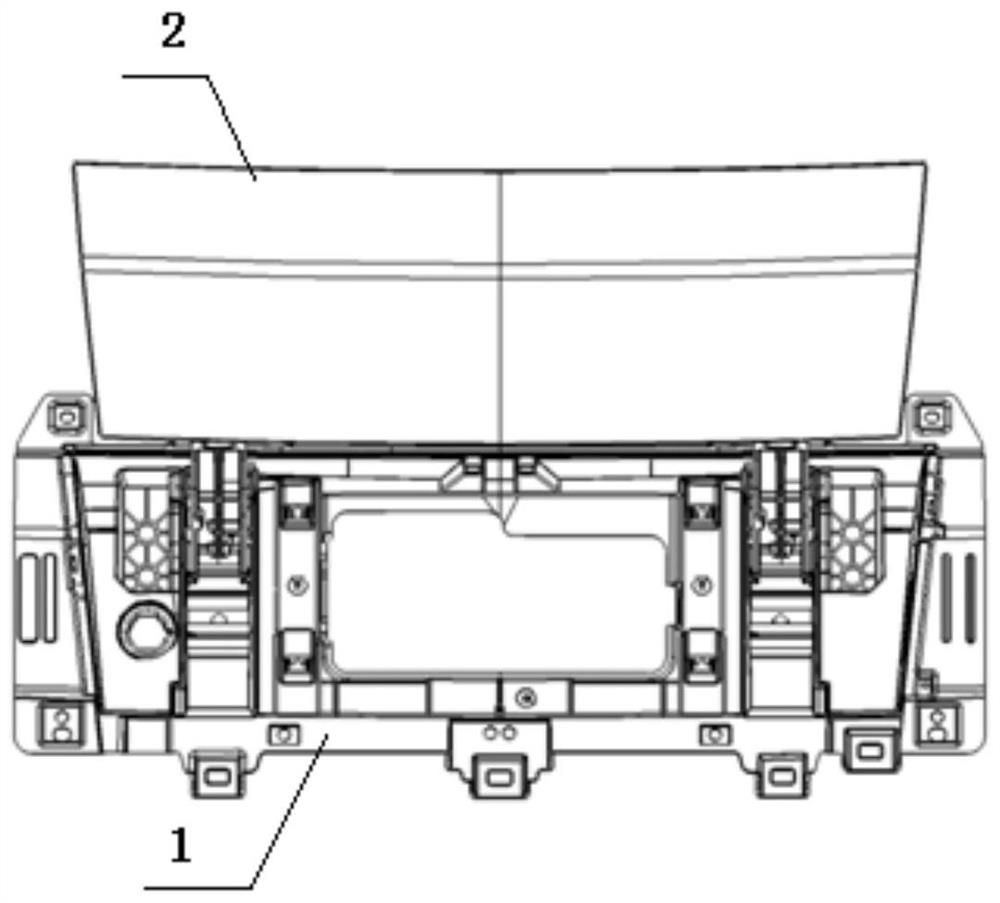

[0038] Such as Figure 1-5 As shown, a front-sliding charging port cover movement mechanism of the present invention is installed on the front of the car and adopts a sliding-up opening method, including a charging port cover body 1 and a charging port that can be closed on the charging port cover body 1 The cover plate assembly 2, slide rod assembly 3, swing arm assembly 4 and blocking cover assembly 5 at the charging port cover body 1 are fixed at the front grille, and the sliding rod assembly 3 is installed on the charging port cover body 1 In the slide bar track on the back side, the slide bar assembly 3 includes the first dead bolt bar 32, the second dead bolt bar 33 and the guide bar 31. When unlocking, the guide bar 31 is pulled horizontally to drive the first dead bolt bar 32 and the second dead bolt bar 32. Two deadbolt rods 33 move v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com