Clothing pleated skirt wrinkle ironing template

A technology for pleated skirts and clothing, applied in textiles and papermaking, heating/cooling fabrics, fabric surface trimming, etc., can solve problems such as low production efficiency and troublesome processes, and achieve improved production efficiency, reduced fabric detachment, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

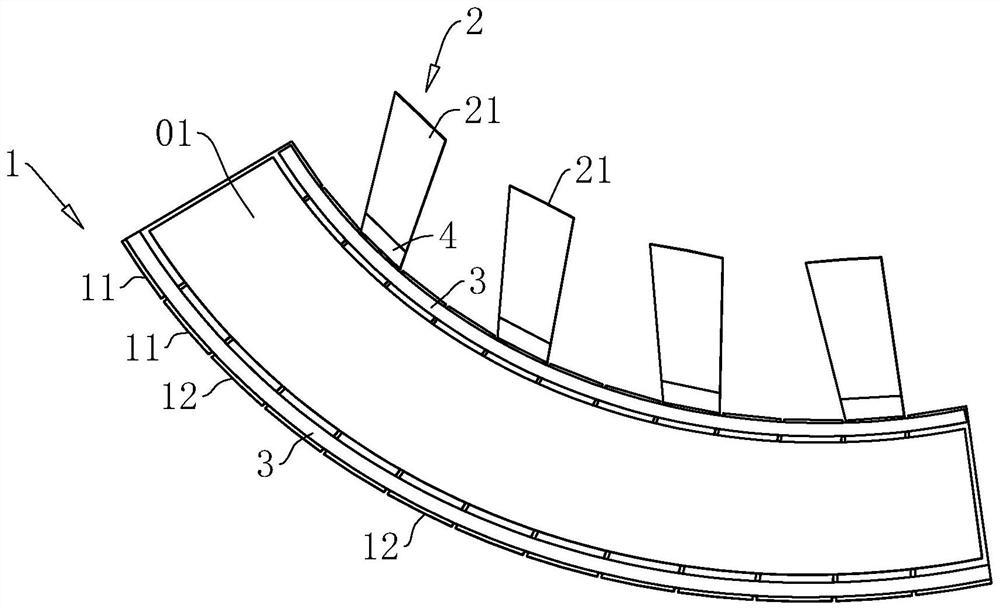

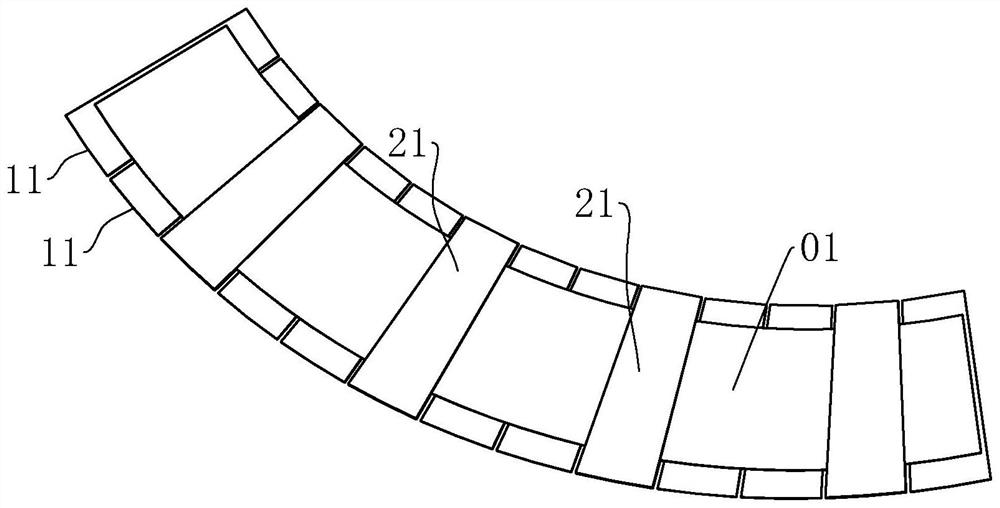

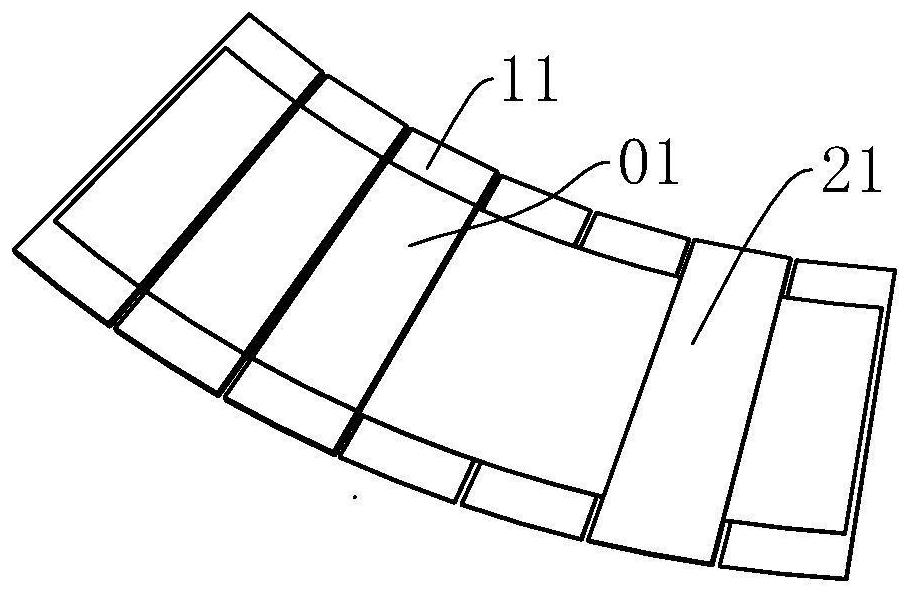

[0046] A garment pleated skirt ironing template, refer to figure 1 with figure 2 , including a bottom mold 1, the bottom mold 1 integrally forms a fan shape, and is used to place cloth 01 on the upper surface of the bottom mold 1, and the bottom mold 1 includes a plurality of folding plates 11 and a plurality of fixed plates 12, and the The shape is the same, and two folded plates 11 are arranged between every two adjacent fixed plates 12, so that a plurality of folded plates 11 and a plurality of fixed plates 12 are arranged in turn to form a fan-shaped bottom mold 1, and two adjacent folded plates 11 are movably connected to each other so that the two folded plates 11 can be folded, and at the same time the adjacent folded plates 11 and fixed plates 12 are movably connected to each other so that the folded plates 11 can be folded up to the fixed plate 12. above. Each fixed plate 12 is provided with a positioning piece 2 for fixing the cloth 01. The positioning piece 2 inc...

Embodiment 2

[0050] A garment pleated skirt ironing template, refer to Image 6 The difference with Embodiment 1 is that the positioning member 2 includes two beading bars 22, one end of the beading bar 22 is rotatably connected to the fixed plate 12, and the beading bar 22 is arranged on the side of the fixed plate 12 close to the folded plate 11, the beading bar 22 Located on the upper surface of the fixed plate 12. When in use, first turn the bead 22 horizontally so that the bead 22 is separated from the position for placing the cloth 01, then place the cloth 01 on the upper surface of the bottom mold 1, and then reversely rotate the bead 22 to the position of pressing the cloth 01, Furthermore, when the folding plate 11 is folded, the side of the bead 22 close to the folding plate 11 can restrict the fabric 01 to facilitate the folding of the fabric 01 . The bead 22 can be made of steel plate or epoxy board. When the bead 22 rotates to the upper surface of the cloth 01, the cloth 01 c...

Embodiment 3

[0052] A garment pleated skirt ironing template, refer to Figure 7 The difference from the first embodiment is that the positioning member 2 includes a rubber band 23 , one end of the rubber band 23 is fixed on the fixed plate 12 , and the other end is provided with a hidden buckle 231 . The rubber band 23 can be tightened by the concealed buckle 231 and both ends are connected to the fixed plate 12 , and the length direction of the rubber band 23 is parallel to the edge where the fixed plate 12 where the rubber band 23 is located is connected to the flap 11 . When in use, first loosen the rubber band 23 from the fixed plate 12 by setting one end of the concealed buckle 231, then lay the cloth 01 on the bottom mold 1; then connect the rubber band 23 to the fixed plate 12 through the concealed buckle 231 , and the rubber band 23 is located on the upper surface of the fabric 01, and finally the flap 11 is folded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com