Method for horizontally pushing and integrally ejecting in place for a ladle rotary table upper-part rotary body

A large-package rotary table and integral jacking technology, applied in the direction of lifting device, can solve the problems of unfavorable installation and operation in production coordination, increase in construction cost, etc., and achieve good popularization and application value, uniform jacking force control, and high support strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further illustrated below by specific examples.

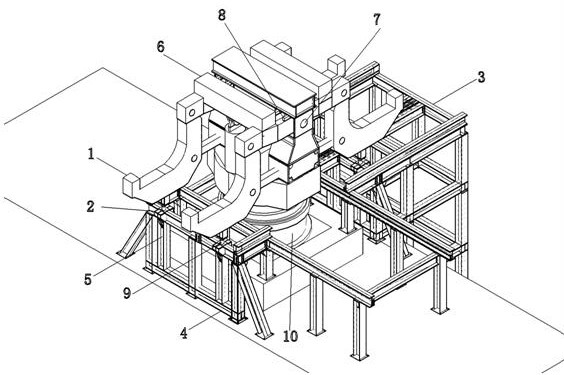

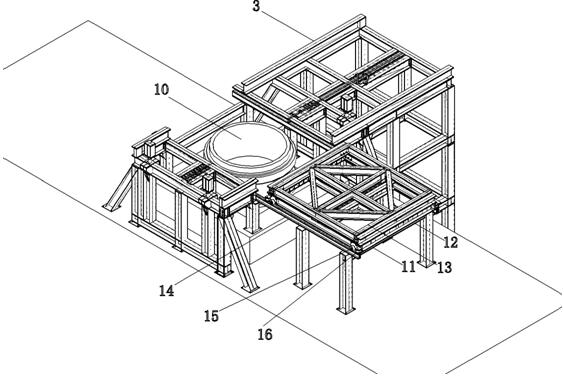

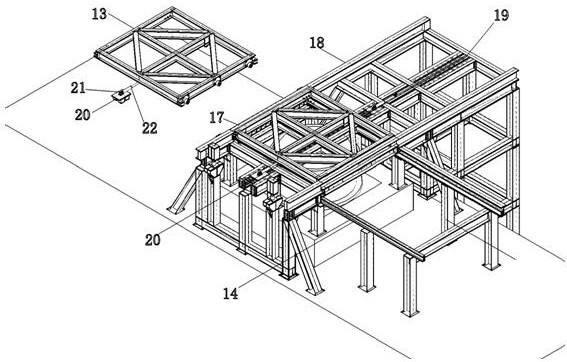

[0029] A method for horizontally moving the upper part of a bale turntable and lifting it into place as a whole, including

[0030] Step 1, jacking fulcrum setting;

[0031] The jacking fulcrum (2) is set under the ladle arm (1) of the ladle turret, the jacking fulcrum (2) is located on the beam (4) of the moving platform (3), and the ribs are set between the upper and lower wings of the beam (4) To improve the support strength, set up a steel column (5) under the jacking fulcrum (2) to transfer the jacking force to the lower beam (4) of the push platform (3) and evenly disperse it to the foundation platform;

[0032] Step 2. The upper rotating body is lifted as a whole;

[0033] Reinforce the ladle arm (1) of the ladle turret first, and install a rectangular billet (8) at the fixed pin shaft (7) on the top of the tower of the upper revolving body (6) so that the ladle arms (1) on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com