High-speed vacuumizing and protective gas filling can sealing production line

A technology of vacuuming and protecting gas, which is applied in the direction of pressurization/gasification packaging, packaging, etc., which can solve the problems of refilling the tank with air, reducing the service life of the sealing ring, and increasing the risk of powder accumulation, so as to reduce Uncertainty factors, quality assurance, and the effect of occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

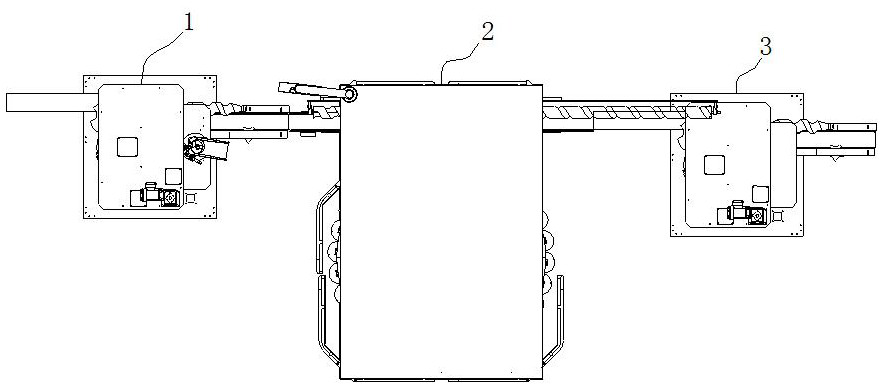

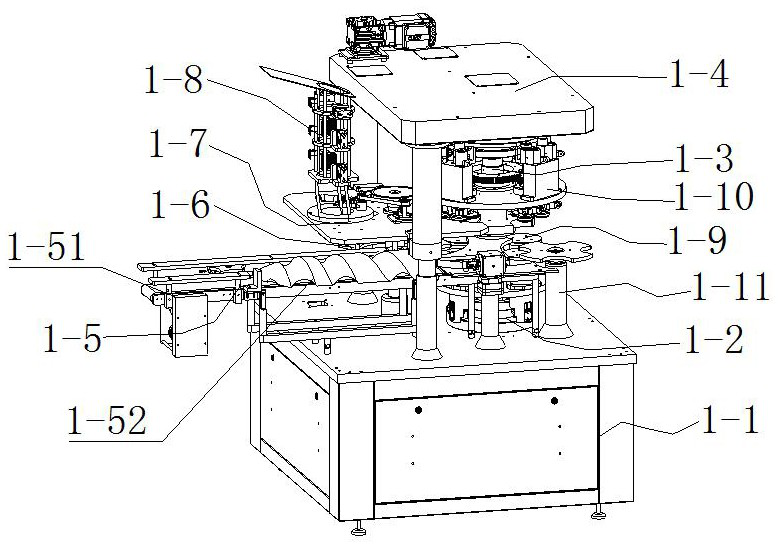

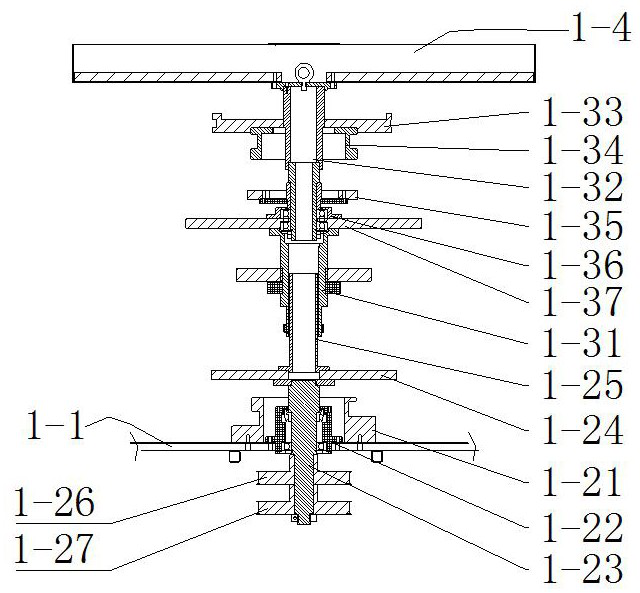

[0056] See figure 1 and Figure 16 , The present invention includes a high-speed pre-sealing machine 1, a high-speed vacuum filling and protective gas device 2, and a high-speed solid sealing machine 3 connected by a conveyor chain. The high-speed pre-sealing machine 1 has a can seaming frame 1-1, an active rotation mechanism 1-2, a pressure wheel transmission mechanism 1-3, a lifting mechanism 1-4, a can feeding mechanism 1-5, and a can lid feeding driving mechanism 1- 6. Bottom cover mechanism 1-7, cover drop mechanism 1-8, can lifting mechanism 1-9, pressure head mechanism 1-10, can discharge mechanism 1-11, drive mechanism 1-12; active rotation mechanism 1-2 It is arranged on the seaming frame 1-1; the lower part of the pressure roller transmission mechanism 1-3 is set through the coaxial transmission of the spline shaft 1-25 and the active rotation mechanism 1-2; the bottom end of the top cover of the lifting mechanism 1-4 is fixed with The pinch wheel drive mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com