Antenna interconnection structure with good grounding

A technology with good grounding and interconnection structure, applied in antennas, antenna arrays, antenna components and other directions, can solve problems such as poor transmission stability, large signal energy loss, poor maintainability, etc. The effect of reducing signal energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

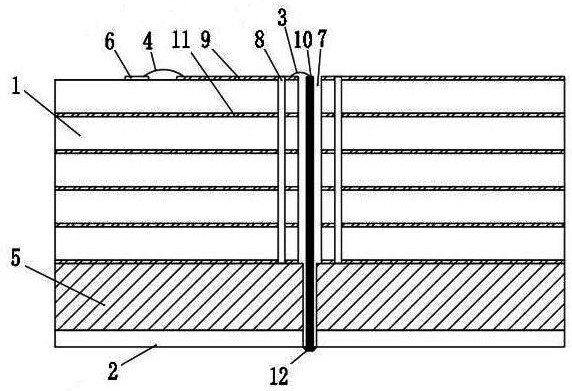

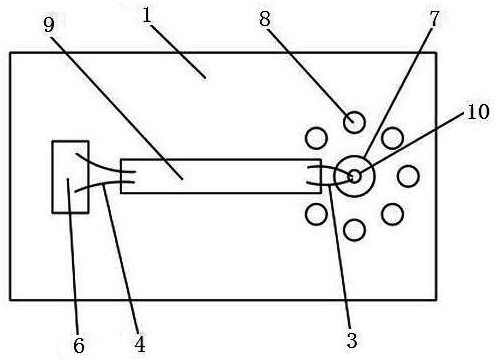

[0033] see figure 1 with figure 2 , a well-grounded antenna interconnection structure, including a multilayer microwave board 1 and an antenna array 2, and also includes a first bonding gold wire 3, a second bonding gold wire 4 and a heat dissipation cavity 5, the multilayer microwave board 1 is A radio frequency circuit board with at least two conductive layers stacked, the multilayer microwave board 1 is fixed on the top of the heat dissipation cavity 5, the antenna array 2 is fixed on the bottom of the heat dissipation cavity 5, and the multilayer microwave board 1 is bonded with The chip 6 is provided with a conduction hole 7 and a coaxial ground hole 8 on the multilayer microwave board 1, and the conduction hole 7 and the coaxial ground hole 8 communicate with the heat dissipation cavity 5 respectively. The microstrip line 9 and the insulator 10, the coaxial ground hole 8 is respectively connected to the microstrip line 9 and the ground 11 of the microstrip line, and on...

Embodiment 2

[0036] see figure 1 with figure 2 , a well-grounded antenna interconnection structure, including a multilayer microwave board 1 and an antenna array 2, and also includes a first bonding gold wire 3, a second bonding gold wire 4 and a heat dissipation cavity 5, the multilayer microwave board 1 is A radio frequency circuit board with at least two conductive layers stacked, the multilayer microwave board 1 is fixed on the top of the heat dissipation cavity 5, the antenna array 2 is fixed on the bottom of the heat dissipation cavity 5, and the multilayer microwave board 1 is bonded with The chip 6 is provided with a conduction hole 7 and a coaxial ground hole 8 on the multilayer microwave board 1, and the conduction hole 7 and the coaxial ground hole 8 communicate with the heat dissipation cavity 5 respectively. The microstrip line 9 and the insulator 10, the coaxial ground hole 8 is respectively connected to the microstrip line 9 and the ground 11 of the microstrip line, and on...

Embodiment 3

[0040] see figure 1 with figure 2, a well-grounded antenna interconnection structure, including a multilayer microwave board 1 and an antenna array 2, and also includes a first bonding gold wire 3, a second bonding gold wire 4 and a heat dissipation cavity 5, the multilayer microwave board 1 is A radio frequency circuit board with at least two conductive layers stacked, the multilayer microwave board 1 is fixed on the top of the heat dissipation cavity 5, the antenna array 2 is fixed on the bottom of the heat dissipation cavity 5, and the multilayer microwave board 1 is bonded with The chip 6 is provided with a conduction hole 7 and a coaxial ground hole 8 on the multilayer microwave board 1, and the conduction hole 7 and the coaxial ground hole 8 communicate with the heat dissipation cavity 5 respectively. The microstrip line 9 and the insulator 10, the coaxial ground hole 8 is respectively connected to the microstrip line 9 and the ground 11 of the microstrip line, and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com