Bullet nest device of large-caliber artillery explosive filling device

A loading device and large-caliber technology, which is applied in ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of inconvenient delivery of shells, slow filling speed of shells, and large push wear, so as to save manpower and time and improve loading speed Fast, the effect of increasing the filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

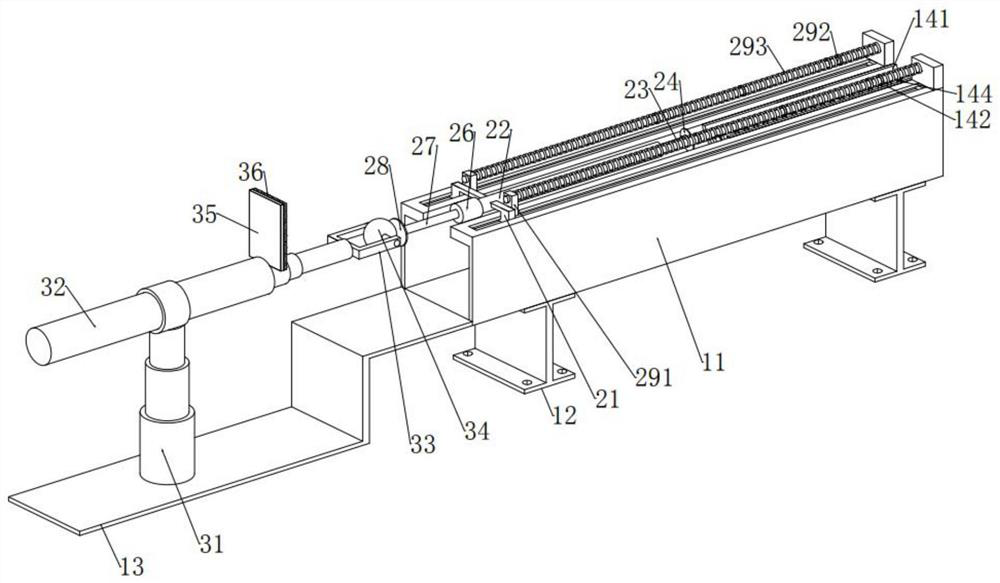

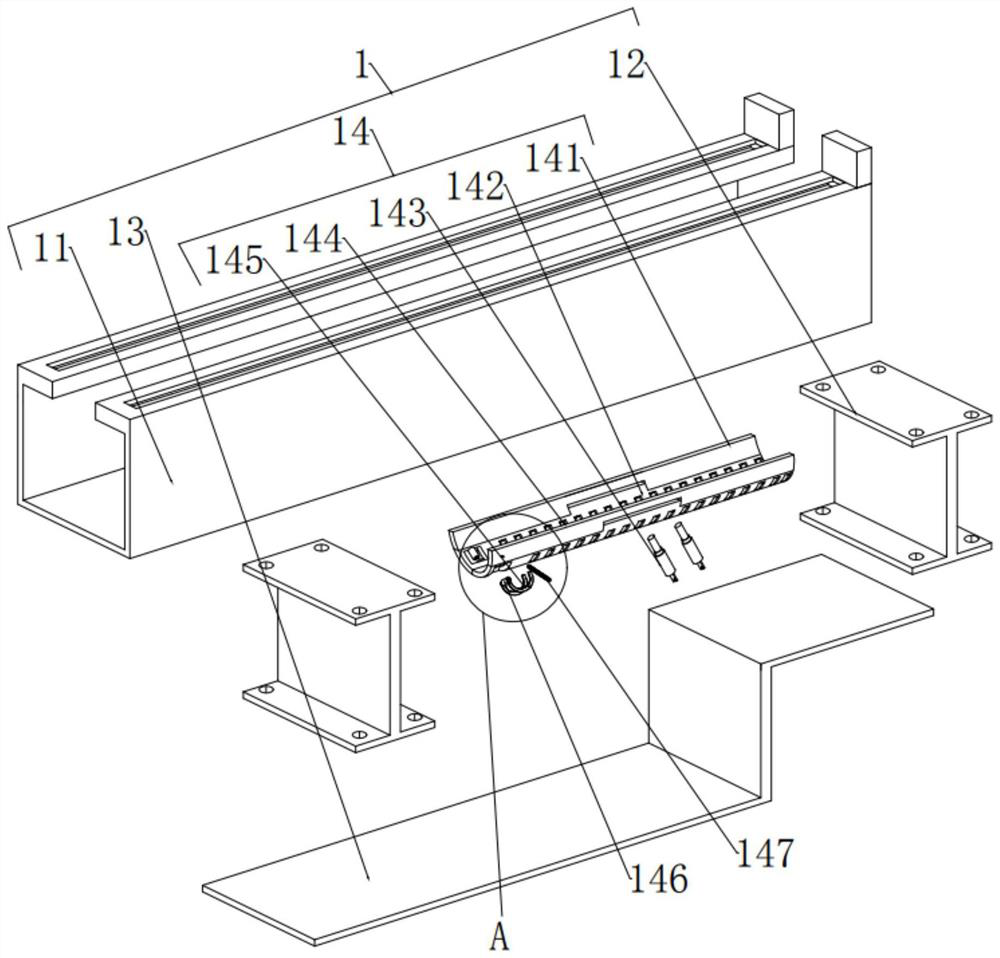

[0049] Embodiment: according to specification Figure 1-7 It can be seen that, firstly, the bearing box 11 is fixed to a certain height through the bearing seat 12 in the bearing structure 1, and then fixedly connected with the docking plate 13 to realize the overall support body, and then after the equipment is energized, the shells can be manually placed in the magazine assembly The left end in the second tank body 142 in 14, and then by the gravity of the shell, squeezes the limit roller 146 on the overturning frame 145 downwards, and then makes it be turned over by the overturning frame 145 to the inversion opening under force, and can apply force to the Cannonball, push it to the other end of the second tank body 142 by means of the guide wheel 144 for a certain distance until it passes the limit roller 146, then stops it, and can be attached to the limit roller 146 side wall for limit;

[0050] Secondly, by driving the second hydraulic cylinder 32 in the power structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com