High-purity MTBE process method for efficiently removing isobutene and preparation system thereof

A process method and technology of isobutene, applied in the direction of preparation of ether by addition of unsaturated compounds, preparation of ether, chemical industry, etc., can solve the problems of long system flow, low conversion rate of isobutene, high energy consumption of operation, etc., and achieve simplified equipment composition, applicable Wide range of types and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

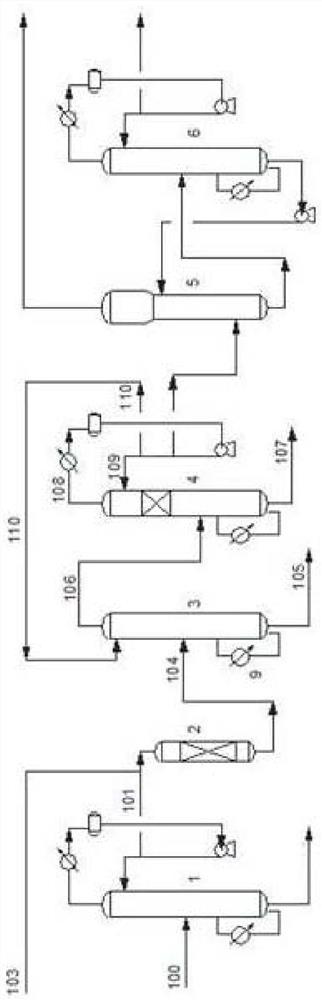

[0021] The high-purity MTBE process method for efficient removal of isobutene in this patent application is to use industrial mixed C4 and methanol as raw materials, improve the conversion rate of isobutene through the etherification pre-reaction part and catalytic rectification part, and prepare high-purity MTBE at the same time, so that the obtained MTBE meets its high technical index requirements for purity as a chemical raw material, so that the remaining carbon four meets its technical index requirements for low isobutene content as a butene raw material. In this preparation process flow, a rectification separation part is connected in series between the etherification pre-reaction part and the catalytic rectification part to separate the MTBE product stream from the product stream of the etherification pre-reaction part. The final intermediate product vapor phase stream is sent to the catalytic rectification section, and the unreacted isobutene in the intermediate product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com