Rubber pipeline laying device

A rubber pipe and arc-shaped technology, which is applied in the direction of pipe supports, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as increased wear, low pipes, and poor stabilization functions, so as to achieve orderly construction and smooth pipes. The effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

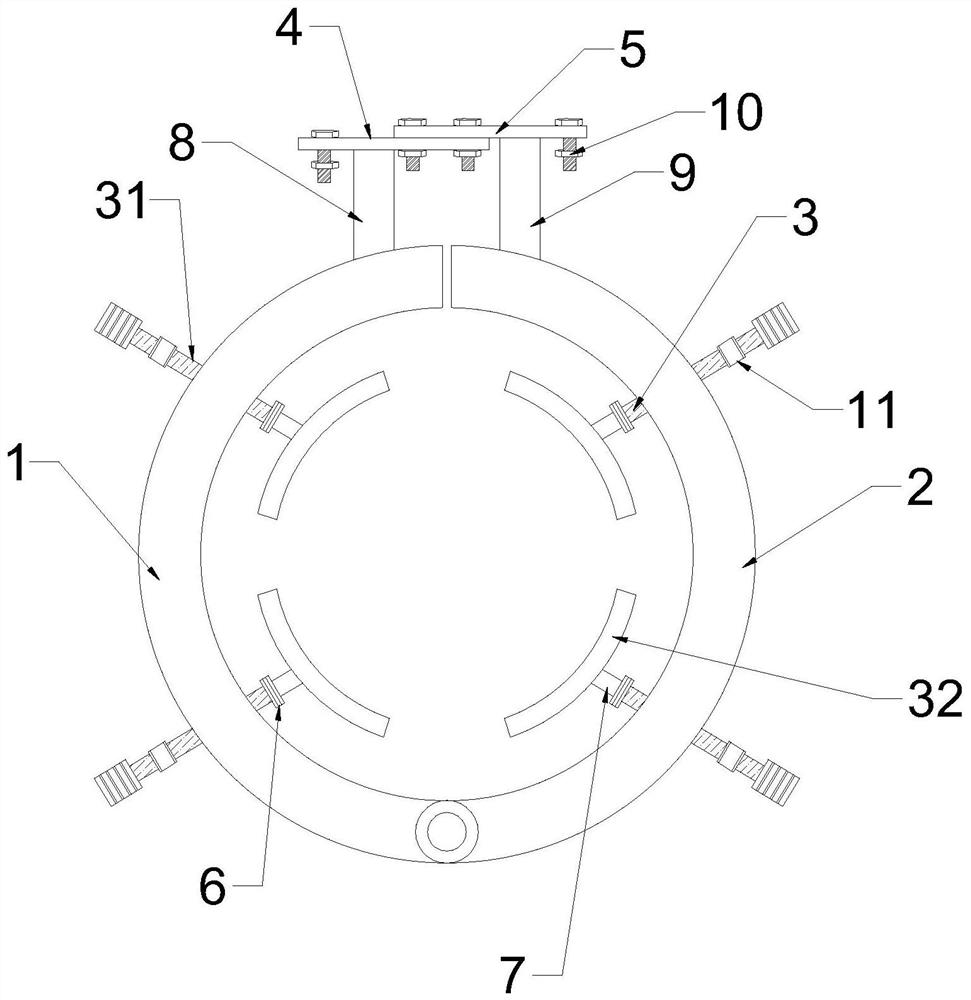

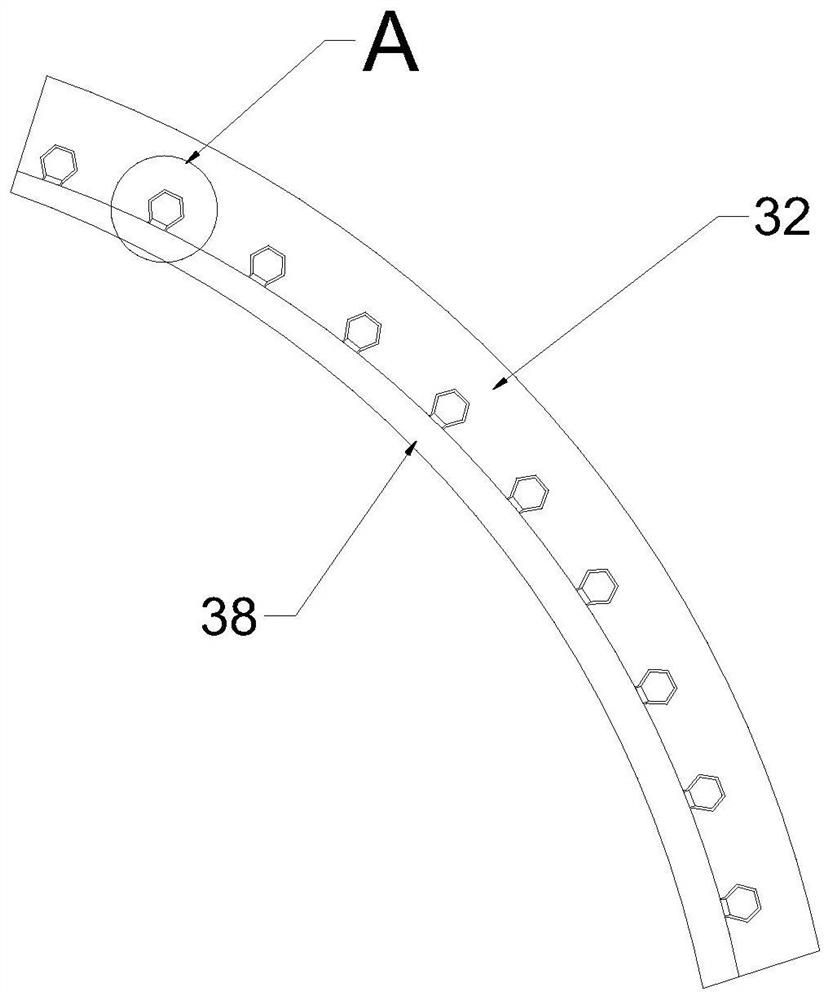

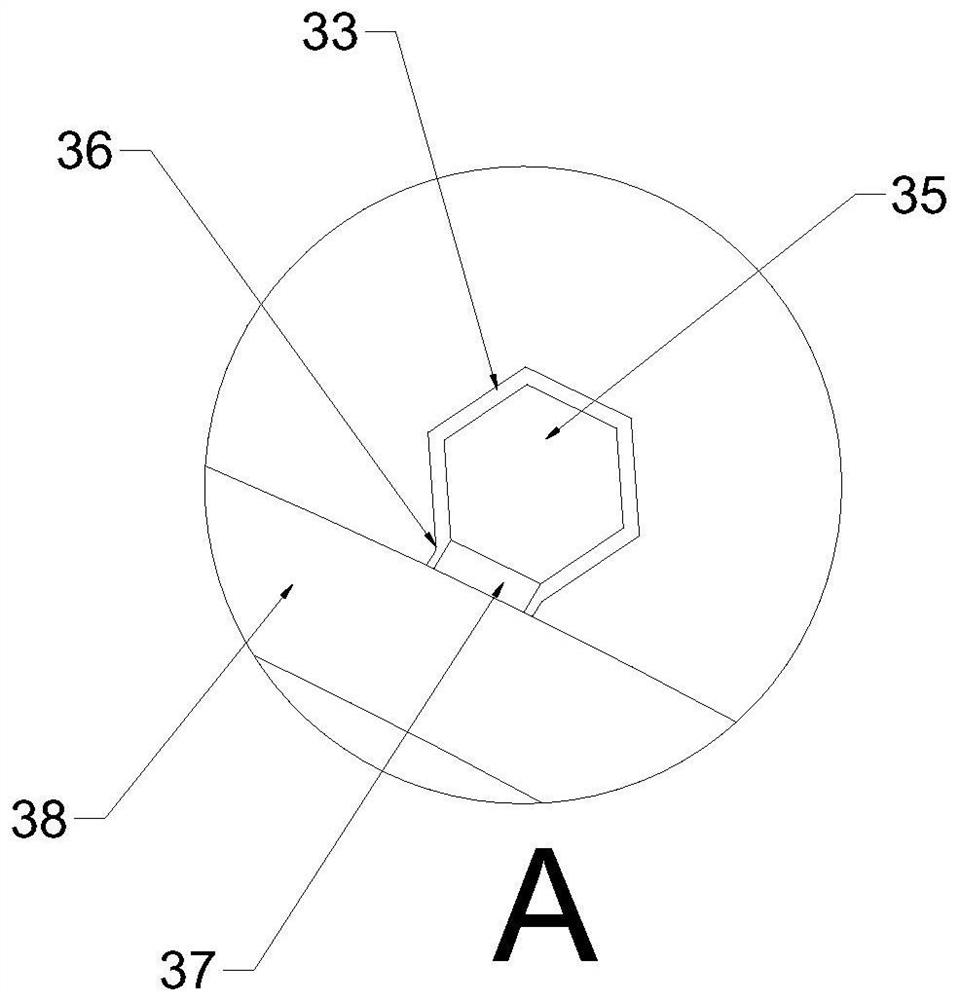

[0019] Such as Figure 1 to Figure 3 As shown, the present invention is a rubber pipeline laying device, including an arc-shaped clamping limiting plate 1, an arc-shaped clamping limiting plate 2 2, an abutment fastening component 3, a fixed plate 1 4 and a fixed plate 2 5 , the abutment fastening assembly 3 includes a push fastening screw 31, an arc-shaped abutment plate 32, a rotating assembly 6 and a mounting plate 7;

[0020] The bottoms of the arc-shaped clamping limit plate 1 and the arc-shaped clamping limit plate 2 are hinged through the hinge assembly, and the upper part is welded with the ear plate 1 8 and the ear plate 2 9, and the height of the ear plate 1 8 is lower than the ear plate The height of two 9, ear plate one 8 and ear plate two 9 are correspondingly fixedly connected with fixed plate one 4 and fixed plate two 5, and the overlapping parts of fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com