Fabricated roof waterproof module

A prefabricated and gutter technology, applied to roofs, roof coverings, building roofs, etc., can solve problems that affect the overall structural performance of the roof, unfavorable upgrade of the functions above the building, and affect the waterproof performance of the building, so as to achieve light weight and waterproof performance. High, easy leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

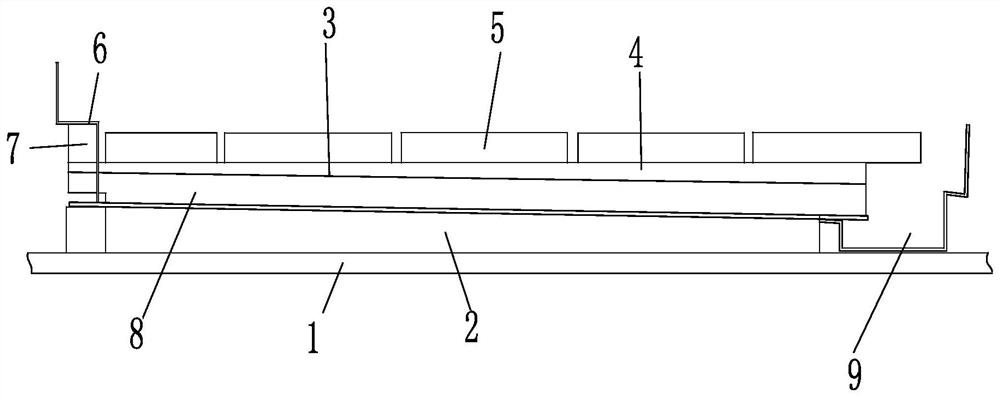

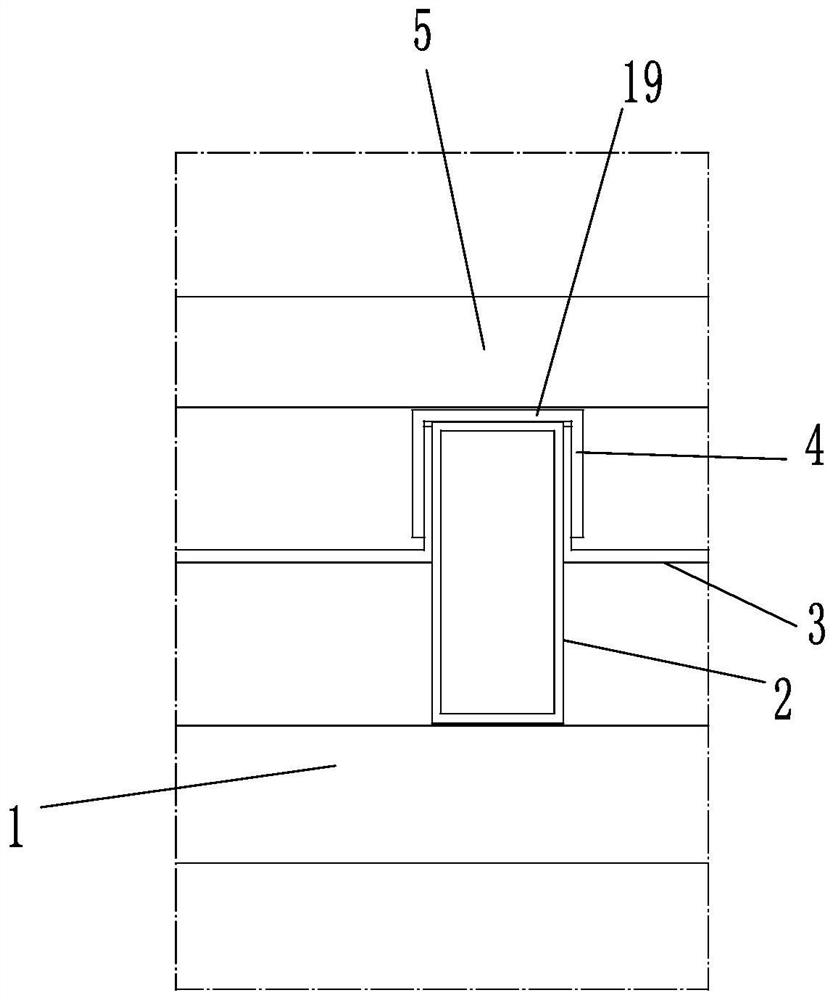

[0028] Example 1, such as Figure 1 to Figure 4 As shown, a prefabricated roof waterproof module includes an European pine board 1 and several plastic-wood keels 2 fixedly connected to the European pine board 1, and the plastic-wood keel 2 adopts a 50*70 square tube. A color steel plate 3 is provided across adjacent plastic-wood keels 2, and a waterproof leveling cover 4 is provided on the outside of the plastic-wood keel 2, and the leveling cover 4 is made of a metal material. The outer side of the leveling cover plate 4 is provided with several elongated plastic wood floorings 5; The axis of the leveling cover plate 4 and the axis of the plastic wood floor 5 are vertically installed; the outer side of the European pine board 1 is fixedly provided with a blocking plate 6 matching the color steel plate 3, and the blocking plate 6 is made of a metal material. The blocking plate 6 is equipped with a waterproof coiled material 7; the joint position of the blocking plate 6 and th...

Embodiment 2

[0032] A prefabricated roof waterproof module, such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the limiting plate includes a first fixing plate 10, an adjusting plate 11 and a second fixing plate 12 arranged outwards from the top plate 19 in sequence, and the first fixing plate 10 and The shape of the second fixed plate 12 is a flat plate, and the adjusting plate 11 is an arc panel that is convexly arranged. The second fixed plate 12 is provided with several positioning and fixing holes 13, and the first fixed plate 10 is provided with several locking and fixing holes. The hole 14 and the adjustment plate 11 are provided with several parallel fixed slots 15, the number of the fixed slots 15 is the number of the locking and fixing holes 14 minus one, and the fixing slots 15 are corresponding to the middle positions of the two adjacent locking and fixing holes 14. The fixing groove 15 is arranged vertically. Both ends of the second fixin...

Embodiment 3

[0034] A prefabricated roof waterproof module, such as Figure 6 As shown, the difference between embodiment 3 and embodiment 21 is that: the outer side of the second fixed plate 12 lower end is provided with the nail starting surface 16 that forms an acute angle with the second fixing plate 12, and the nail starting surface 16 and the color steel plate 3 on the Self-tapping screws cooperate, and the lower end of the inner side of the adjustment plate 11 is provided with a nail-removing convex angle 17 . The cross-sectional shape of the nail removing lobe 17 is a semicircle. The second fixing plate 12 is provided with partition grooves 18 that match the number of positioning and fixing holes 13 . The separation groove 18 is disposed at a middle position between two adjacent positioning and fixing holes 13 . The setting of the separation groove 18, the nail-lifting surface 16 and the nail-lifting protruding angle 17 enables the second fixing plate 12 to have a nail-lifting ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com