Integrated sand stabilization plate and preparation method and sand stabilization method thereof

A sand-fixing board, an integrated technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of time-consuming and labor-intensive construction of sand-fixing boards, limited construction sand surface, etc., saving manpower and material resources, low cost, and ease of use. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1 (integrated sand-fixing board)

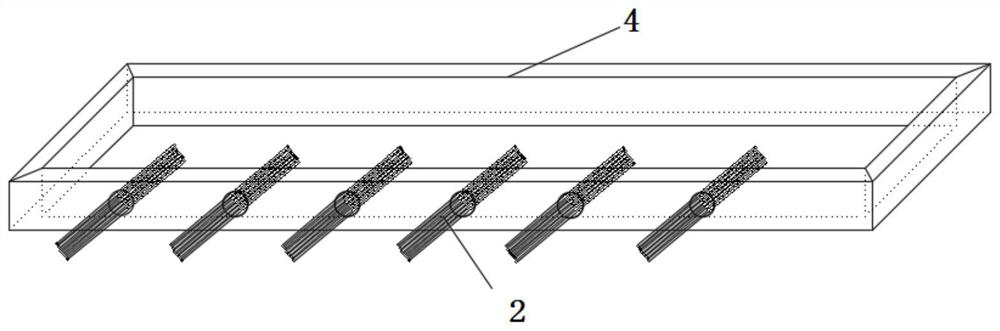

[0070] Such as figure 1 As shown, the integrated sand-fixing board includes a sand-fixing board body 1 and a plurality of magnesium bars 2 fixed on the sand-fixing board body 1, wherein the sand-fixing board body 1 is solidified by magnesium cement mortar, and the magnesium One end of the magnesia tendon 2 is solidified inside the sand-fixing board, and the other end is located outside the body of the sand-fixing board to form a fixed end. pulp.

[0071] The magnesium cement mortar can adopt one of the following examples 2.1-2.3 or any composition in any proportion, and the magnesium cement paste can use one of the following examples 2.1-2.3 or any composition in any proportion.

Embodiment 2

[0074] Embodiment 2 (preparation of magnesium cement clean slurry and magnesium cement mortar)

[0075] The water in the following embodiments is not limited, it can be tap water or river and lake water.

[0076] 2.1 Preparation of magnesium oxychloride cement paste and magnesium oxychloride cement mortar

[0077] Described magnesium oxychloride cement mortar is prepared by following method:

[0078] Step 1, dissolving magnesium chloride in water to obtain a magnesium salt solution with a concentration between 20-30Be °;

[0079] Step 2, active magnesia, sandy soil (sandy soil is sand and / or soil, obtained from sand control locality) and described magnesium salt solution by mass ratio 1:(5-15):(0.5-1.5) (optimum ratio 1:8:0.9, in addition, 1:5:1.5, 1:15:0.5, 1:5:0.5) can also be used to mix and stir evenly to obtain magnesium oxychloride cement mortar.

[0080] The magnesium oxychloride cement clean slurry is prepared by the following method:

[0081] Step 1, dissolving ma...

Embodiment 3

[0107] 3.1 Prepare the mold:

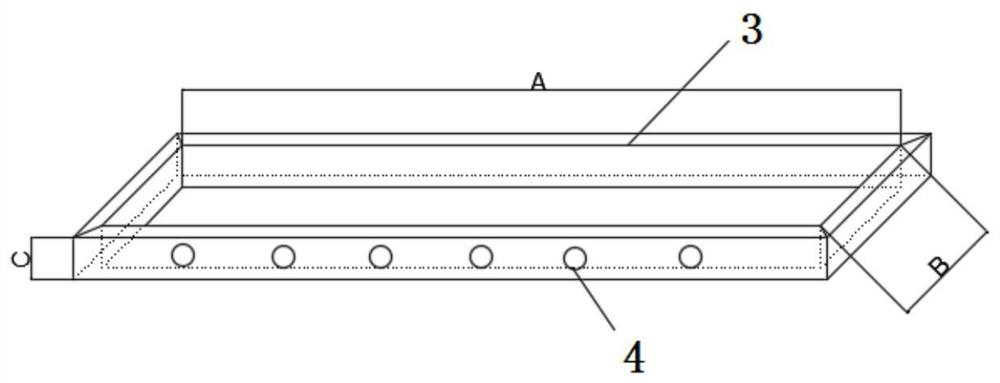

[0108] Made of stainless steel plate as figure 2 The rectangular sand-fixing plate mold shown in the figure includes a bottom plate and four side wall plates. The four corners of the side wall plates are connected by snap buttons, and a number of holes are opened on one of the side wall plates. Hole is provided with six in the present embodiment, and the internal dimension of mold is long (A) * wide (B) * thick (C)=(100cm-200cm) * (20cm-50cm) * (1.5cm-5cm), the hole The diameter is 1cm-2cm.

[0109] 3.2 Preparation of integrated sand-fixing board:

[0110] Step A. prepare magnesium cement clean slurry and magnesium cement mortar 6 according to the method of embodiment 2.1, 2.2 or 2.3:

[0111] Step B. Prepare magnesium bars:

[0112] Bind plant fibers (such as bamboo tendons, straw, reed stalks, etc. or other plant straw materials) into tendons with a diameter smaller than holes, the length of the tendons is 10-30cm, soak the tendons in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com