Catalyst component for olefin polymerization, catalyst system and application

A technology of olefin polymerization and catalyst, applied in the field of olefin polymerization, can solve the problems of low polymerization activity, low polymerization activity and stereoregularity, and insufficient polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

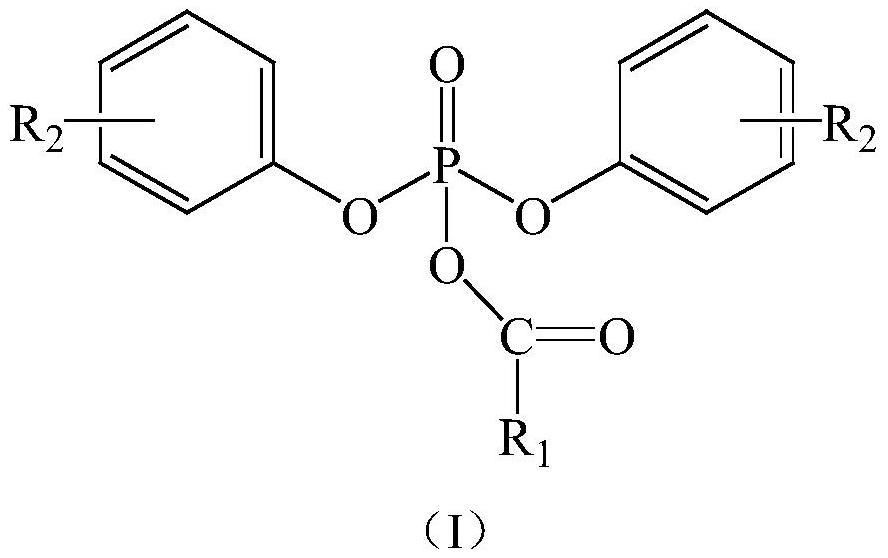

Method used

Image

Examples

Embodiment approach

[0090] According to a preferred embodiment of the present invention, the external electron donor compound includes a compound represented by general formula (III):

[0091] R 2 k Si(OR 3 ) 4-k (III)

[0092] In general formula (III), 0≤k≤3; R 2 is an alkyl group, a cycloalkyl group, an aryl group, a haloalkyl group, an amino group, a halogen or a hydrogen atom; R 3 is alkyl, cycloalkyl, aryl, haloalkyl or amino.

[0093] According to a preferred embodiment of the present invention, R 2 for C 1 -C 10 Alkyl, C 3 -C 10 Cycloalkyl, C 6 -C 20 Aryl, C 1 -C 10 Haloalkyl, amino, halogen or hydrogen atom.

[0094] According to a preferred embodiment of the present invention, R 3 for C 1 -C 10 Alkyl, C 3 -C 10 Cycloalkyl, C 6 -C 20 Aryl, C 1 -C 10 Haloalkyl or amino groups.

[0095] In the catalyst system of the present invention, the alkylaluminum compound has the general formula AlR 4 n x 3-n compounds, where R 4 is hydrogen or a hydrocarbon group with 1-...

Embodiment 1

[0115] Preparation of the solid catalyst component: in a 250ml reactor equipped with a reflux condenser, a mechanical stirrer and a thermometer and fully replaced by nitrogen, add 36.5ml of dehydrated alcohol, 21.3g of anhydrous magnesium chloride, heat up under stirring, and the magnesium chloride is completely After dissolving, add 75ml of white oil and 75ml of silicone oil, and keep at 120°C for a certain period of time. In another reaction bottle with a volume of 500ml and a high-speed stirrer, 112.5ml of white oil and the same volume of silicone oil were added in advance, preheated to 120°C, and the aforementioned mixture was quickly pressed into the second reactor and maintained at 120°C. °C was stirred at 3500rmp for 3 minutes, and under stirring, the material was transferred to the third reactor that had previously added 1600ml of hexane and cooled to -25 °C until the material transfer was completed, and the final temperature did not exceed 0 °C. Suction filtration, wa...

Embodiment 2

[0119] The method is the same as in Example 1, except that the internal electron donor compound is a compound internal electron donor of 4mmol isovaleryloxyphosphate di(4-isopropylphenyl ester) and 1mmol diisobutyl phthalate compound. The activity of the catalyst is 50.1kgPP / (g.cat), the isotactic index is 98.0%, the melt index is 7.9g / 10min, and the molecular weight distribution is 7.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com