Split type barrow

A split-type, object-based technology, applied in the direction of lifting devices, etc., can solve problems such as small space, high price, and large volume of forklifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the split ground cattle of the present invention are given below in conjunction with the illustrations. The embodiments are only illustrations of the present invention and do not constitute limitations to the claims of the present invention. The unmentioned parts of the present invention are applicable to the prior art.

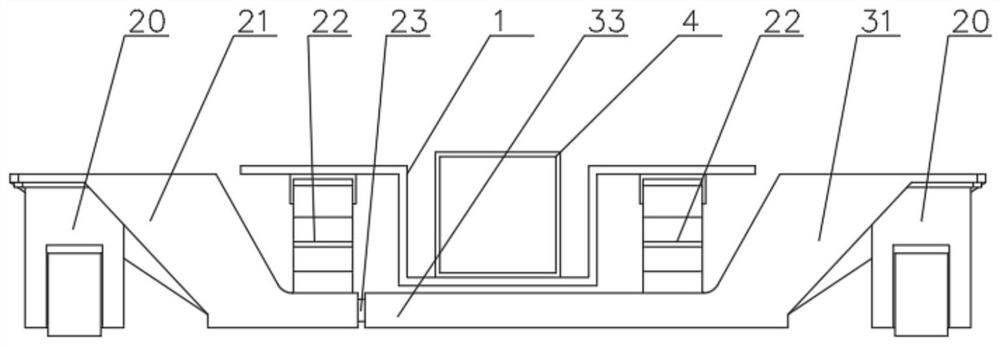

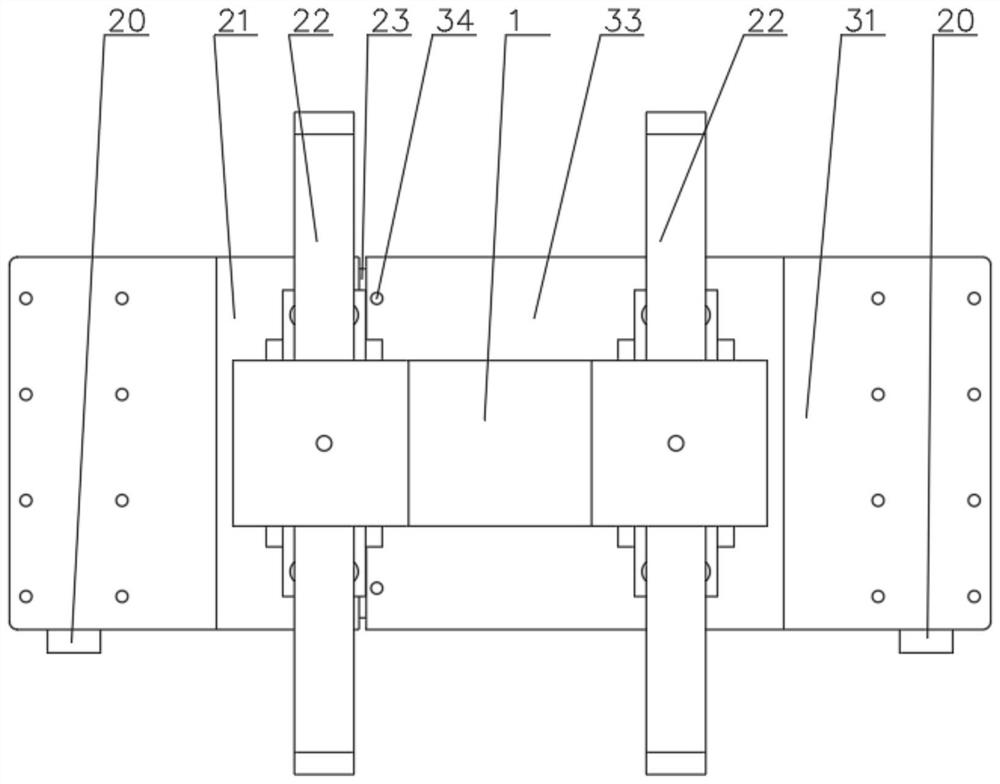

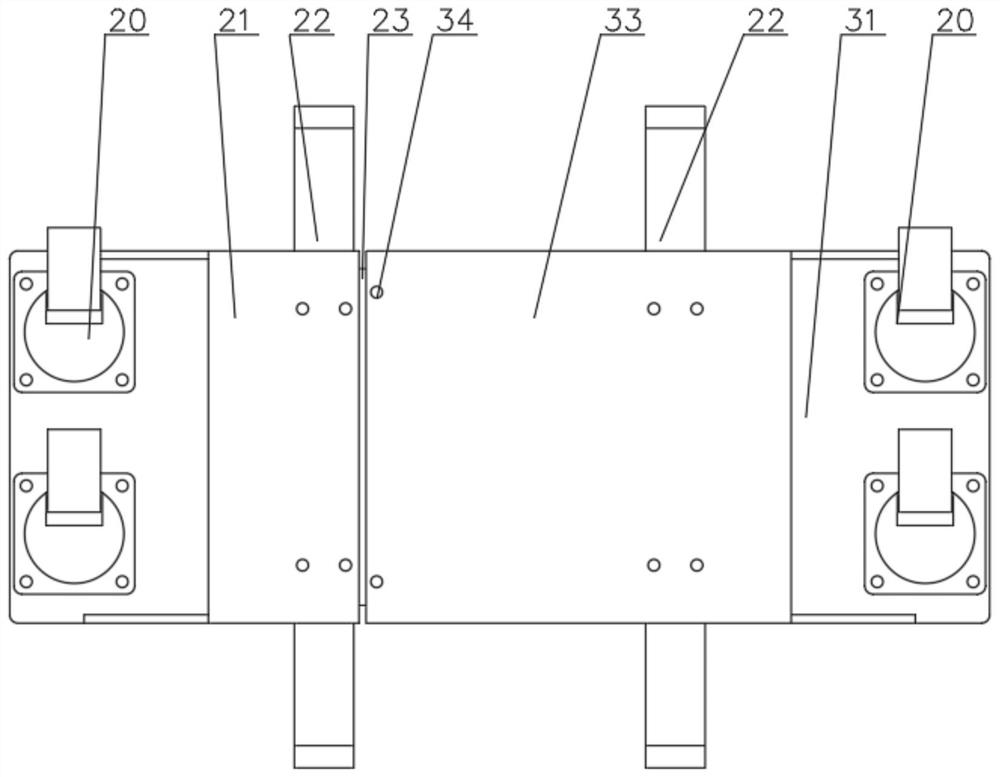

[0019] Embodiment 1 (such as Figure 1~3 shown):

[0020] The split ground cow includes a height-adjusting part 1, a first bearing part and a second bearing part, and the height-adjusting part 1 is an inverted "several"-shaped part

[0021] The first bearing part comprises a first carrier 21 (as a first support structure), a scissor jack 22 installed above the first carrier 21 and two casters 20 installed below the first carrier 21, and the second carrier The parts include a second carrier 31 (as a second support structure), a scissor jack 22 installed above the second carrier 31 and two casters 20 installed below the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com