Pedal bicycle

A bicycle and frame technology, applied in the field of pedal bicycles, can solve the problems of coaxiality, damage to the transmission system, waste of favorable conditions for the driving force arm, etc., and achieve the effects of long force arm, compact structure, and no free travel on the transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

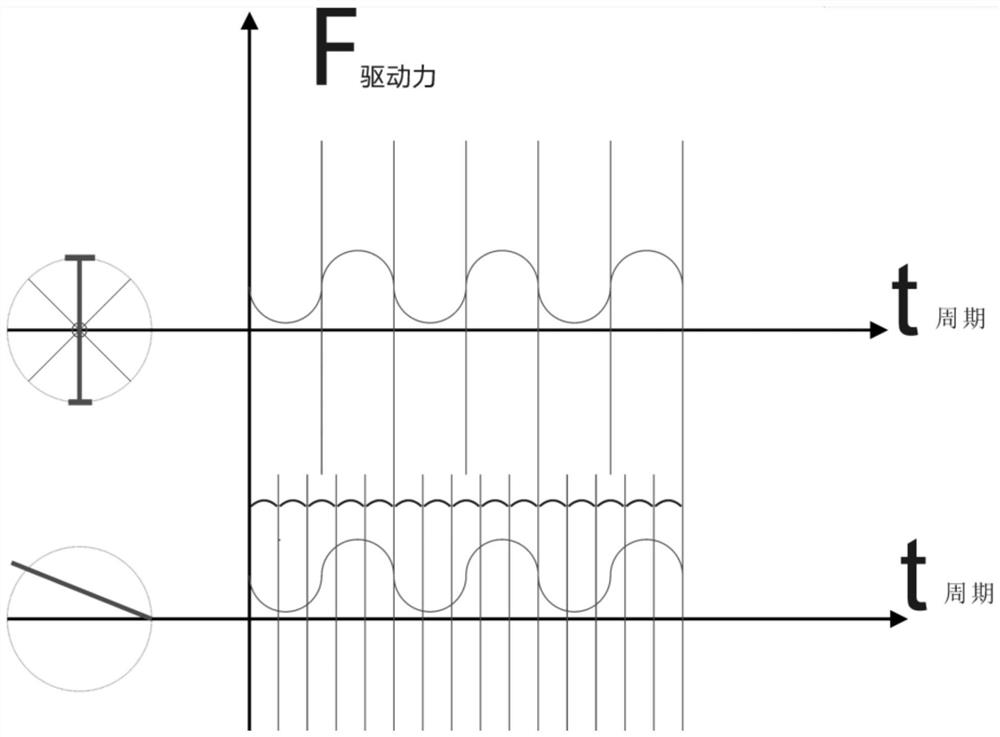

[0048] figure 1 , which is the design efficiency index that guides our design target ideal state, and the output curve of the product power produced by the final design is figure 1 The thick wavy lines with a short period in the lower half have just reached the ultimate beneficial effect of the present invention.

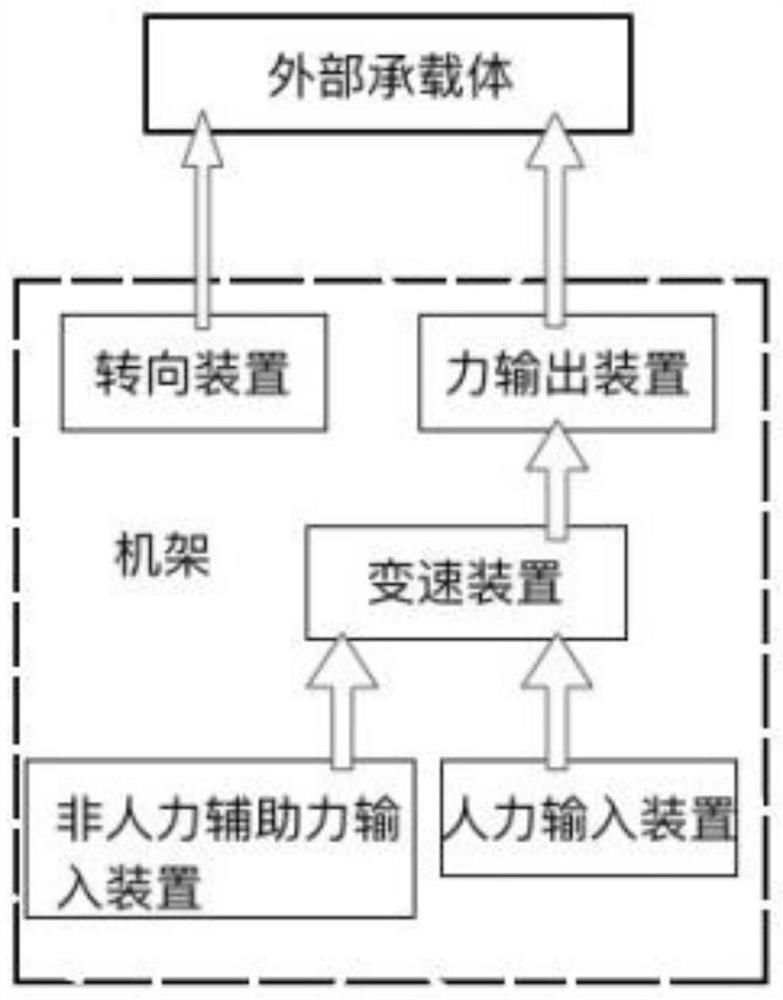

[0049] figure 2 , is exactly the logic diagram between each device of the present invention, and the arrow represents the direction of force transmission, and the force output device is the rear wheel that is connected with the transmission.

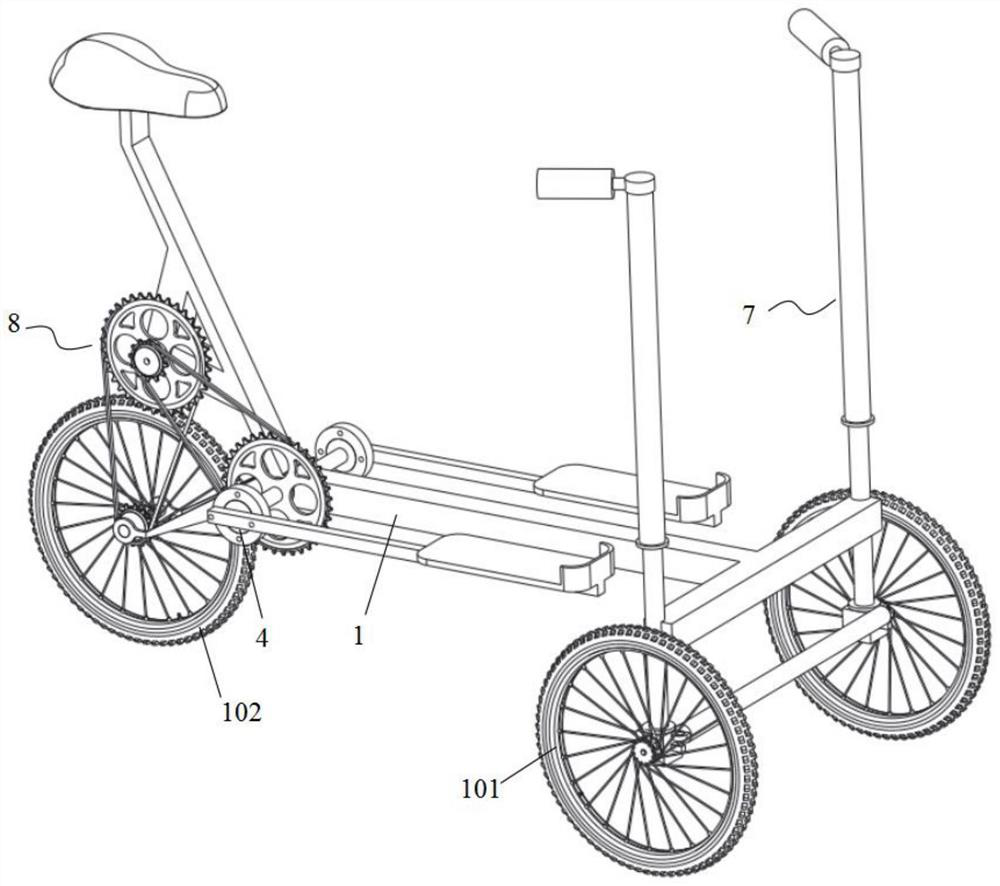

[0050] It includes a vehicle frame 1, and a manual variable speed drive device installed on the vehicle frame, a steering device 7, a front wheel 101, and a rear wheel 102;

[0051] The manpower variable speed driving device includes: frame, force application handle 2, main drive shaft 3, one-way overrunning clutch 4, reset device 6, speed change gear set 8, one end of force application handle is fixed with the input end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com