Unfolding process of green bamboo strips

A technology of bamboo chips and craftsmanship, which is applied in the field of unfolding technology with green bamboo chips, can solve problems such as cracking, high hardness of bamboo greens, and material cracking, and achieve the effects of high efficiency, uniform moisture content, and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

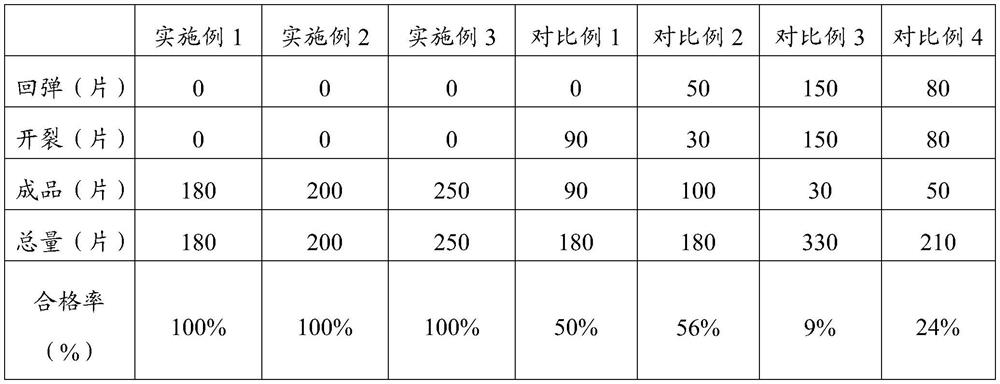

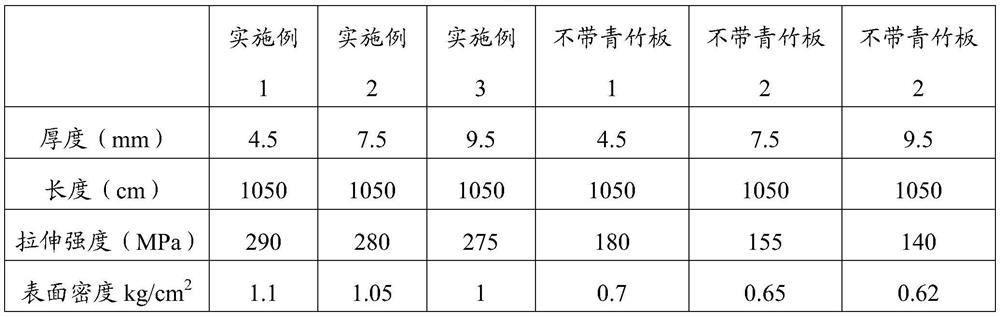

Examples

Embodiment 1

[0029] The unfolding process with green bamboo slices comprises the following steps:

[0030] After step 1, the bamboo is segmented to obtain a bamboo tube, the bamboo tube is cut into bamboo slices with an arcuate cross section;

[0031] The diameter of described bamboo tube is 60-90mm, and the quantity that described bamboo tube is cut into bamboo chips is 3;

[0032] Step 2, the bamboo slices are pressurized and heated to soften, and the softened bamboo slices are unfolded by equal arcs to determine the thickness, and then planed to remove the bamboo yellow;

[0033] Softening conditions under pressure and heating: the pressure is 1.2MPa, the temperature is 200°C, and the time is 3min;

[0034] The expansion of constant arc thickness is as follows: use arc rollers to press the softened bamboo slices into a first-class arc shape, and then process them with equal thickness with arc knives;

[0035] Step 3, the bamboo slices after step 2 equal-arc thickness determination and...

Embodiment 2

[0041] The unfolding process with green bamboo slices comprises the following steps:

[0042] After step 1, the bamboo is segmented to obtain a bamboo tube, the bamboo tube is cut into bamboo slices with an arcuate cross section;

[0043] The diameter of described bamboo tube is 90-120mm, and the quantity that described bamboo tube is cut into bamboo chips is 4;

[0044] Step 2, the bamboo slices are pressurized and heated to soften, and the softened bamboo slices are unfolded by equal arcs to determine the thickness, and then planed to remove the bamboo yellow;

[0045] Softening conditions under pressure and heating: the pressure is 0.8MPa, the temperature is 180°C, and the time is 10min;

[0046] The expansion of constant arc thickness is as follows: use arc rollers to press the softened bamboo slices into a first-class arc shape, and then process them with equal thickness with arc knives;

[0047] Step 3, the bamboo slices after step 2 equal arc thickness determination a...

Embodiment 3

[0053] The unfolding process with green bamboo slices comprises the following steps:

[0054] After step 1, the bamboo is segmented to obtain a bamboo tube, the bamboo tube is cut into bamboo slices with an arcuate cross section;

[0055] The diameter of described bamboo tube is 120-150mm, and the quantity that described bamboo tube is cut into bamboo chips is 5;

[0056] Step 2, the bamboo slices are pressurized and heated to soften, and the softened bamboo slices are unfolded by equal arcs to determine the thickness, and then planed to remove the bamboo yellow;

[0057] Softening conditions under pressure and heating: pressure 1.3MPa, temperature 160°C, time 7min;

[0058] The expansion of constant arc thickness is as follows: use arc rollers to press the softened bamboo slices into a first-class arc shape, and then process them with equal thickness with arc knives;

[0059] Step 3, the bamboo slices after step 2 equal arc thickness determination and unfolding are graduall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com