Soft crawling robot and control method thereof

A technology of crawling robot and robot body, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of large size and few gripping robots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

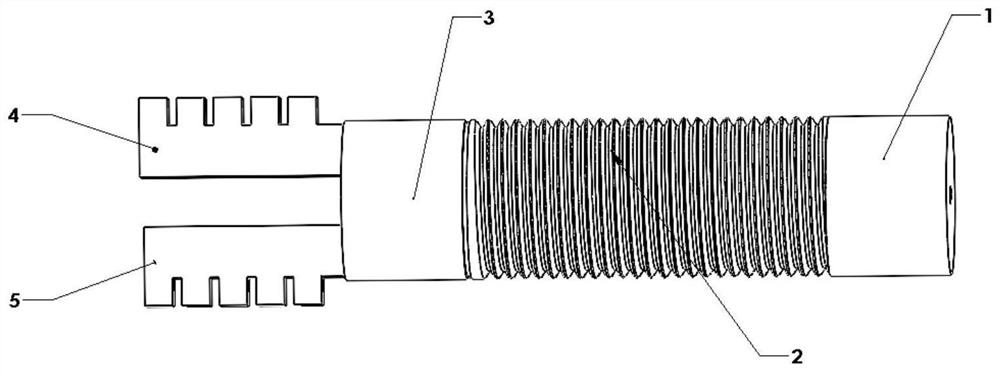

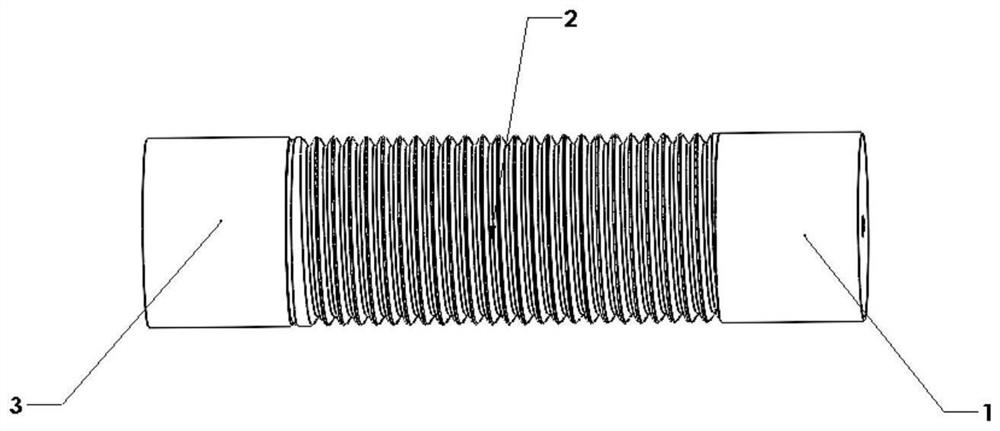

[0038] refer to Figure 1-Figure 3 As shown, a soft crawling robot of the present invention, the soft crawling grabbing robot includes: a robot body, a robot gripper, and an airway assembly, and the robot body includes sequentially connected front end radial actuators 3, central axial Executor 2, rear end radial actuator 1, the robot gripper includes a plurality of soft grippers connected with the robot body;

[0039] The soft gripper includes a finger-shaped structure air cavity 7, and the finger-shaped structure air cavity 7 is provided with a back cover 6, and the Young's modulus of the material of the back cover 6 is greater than that of the finger-shaped structure air cavity 7 material, and the plurality of grips The hand is inflated into a curved shape and grasps the object to be grasped. In this embodiment, there are two soft grippers, namely the first soft gripper 4 and the second soft gripper 5;

[0040] The front radial actuator 3 and the rear radial actuator 1 incl...

Embodiment 2

[0048] The present embodiment provides the method for making the above-mentioned soft robot, including:

[0049] Step S1: Design the structure of the soft robot according to the requirements, and give the specific dimensions of each part. The diameter of the front and rear radial actuators is 35mm, and the length is 24mm. The diameter of the central axial actuator is 35mm, and the length is 80mm. The hand length is 42mm, the size of the top air cavity is 4×2×6mm, the size of the back cover is 42×8×3mm, and the wall thickness of the above parts is 2mm;

[0050] Step S2: According to the structure and size designed in step S1, use SolidWorks 3D modeling software to draw a series of molds that match each part of the robot for printing, and take into account the accuracy of the printer, and finally draw the completed mold save in a specific format;

[0051] Step S3: Import the mold drawing completed in step S2 into the slicing software of the 3D printer, set the parameters such a...

Embodiment 3

[0058] This embodiment provides a method for making a robot gripper, including the following steps:

[0059] Step S1: Use SolidWorks software to draw the soft gripper mold for 3D printing, including the upper and lower layers of the mold for making the top of the gripper and the bottom mold of the gripper for pouring the back cover material, such as Figure 5 , 6 , 7 shown. After the drawing is completed, save it in stl format, import it into the slicing software supporting the 3D printer, set the printing quality, internal filling density, filling style, shell, printing thickness, printing speed and other parameters and start printing. After printing, wait for cooling and take out the mold , and post-processing to remove blemishes;

[0060] Step S2: Take an appropriate amount of release agent and apply it evenly on the surface of the mold to facilitate subsequent demoulding work;

[0061] Step S3: Weigh an appropriate amount of silicone rubber for pouring into the mold, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com