Double-sided scrubbing device for wafer processing

A double-sided, wafer technology, applied in the cleaning method using tools, the cleaning method using liquid, and the arrangement of drying gas, etc., can solve the problems of easy re-adsorption of impurities, low brushing efficiency, and inability to brush the wafer, etc. Brushing effect, improve brushing efficiency, avoid the effect of re-adsorbing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

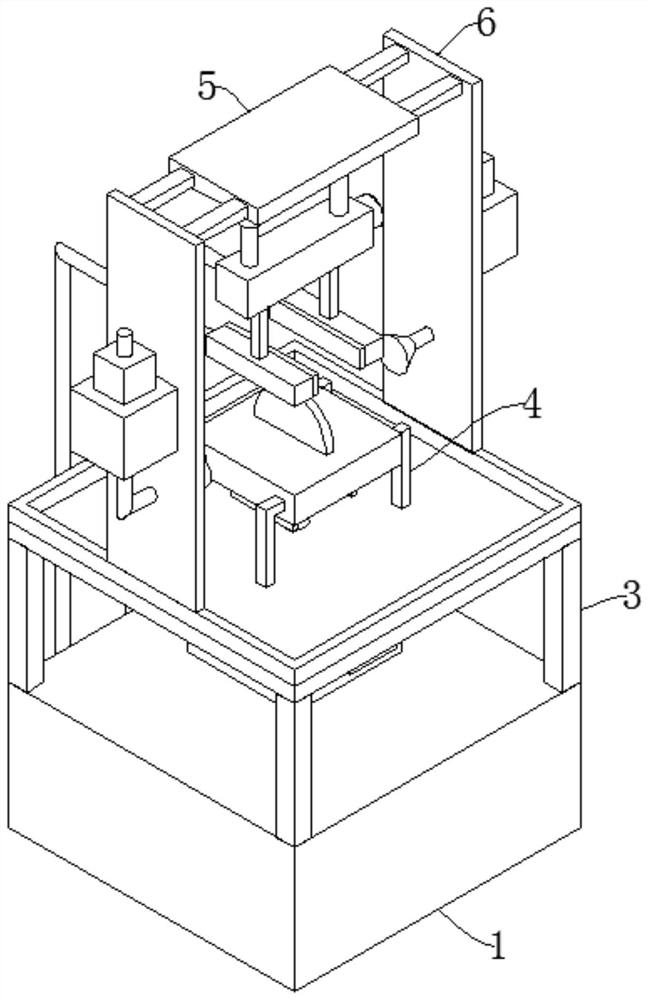

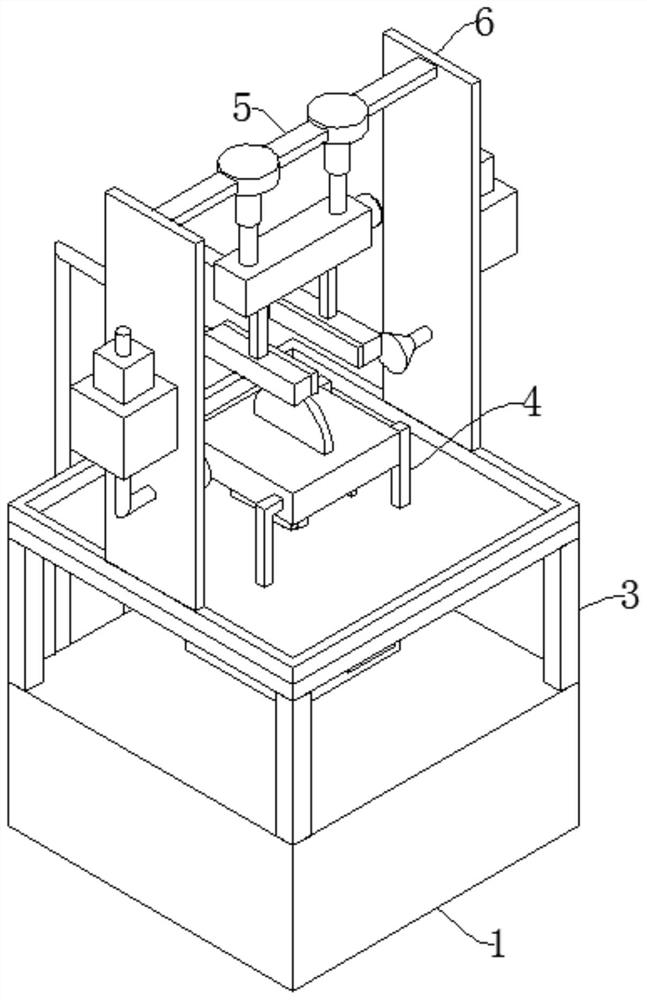

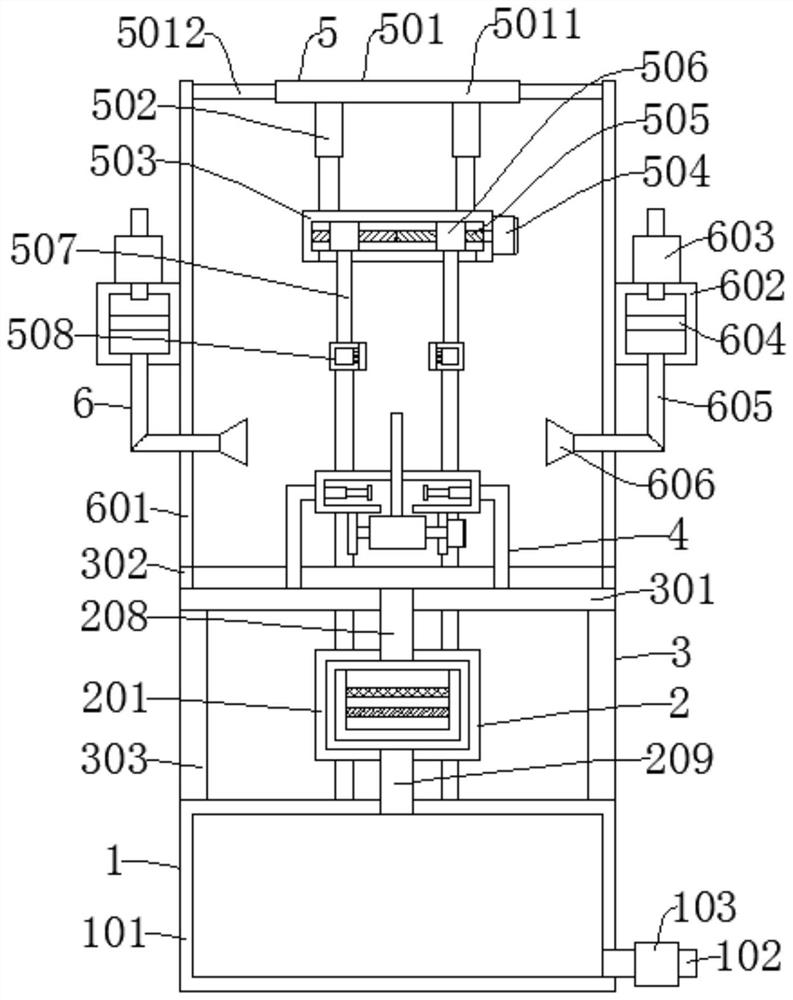

[0051] Such as figure 1 , image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, a double-sided brushing device for wafer processing includes a water supply mechanism 1 for providing water resources for brushing, a filter mechanism 2 for filtering sewage, and a support mechanism 3 for supporting the upper equipment. A filter mechanism 2 is installed above the water supply mechanism 1, and a support mechanism 3 is arranged above the filter mechanism 2, and also includes a mounting mechanism 4 for installing the wafer 404, a scrubbing mechanism 5 for simultaneously scrubbing both sides of the wafer 404, and a The drying mechanism 6 for drying the scrubbed wafer 404, the installation mechanism 4 is fixed above the support mechanism 3, the scrubbing mechanism 5 is arranged above the installation mechanism 4, and the drying mechanism 6 is fixed on both sides of the scrubbing mechanism 5;

[0052] The mounting mechanism 4 includes a mounting seat 401, a...

Embodiment 2

[0058] Such as figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the difference between Embodiment 2 and Embodiment 1 is that the fixed plate 5011 and the fixed rod 5012 are replaced by a cross bar 5013 and a fixed plate 5014. The equipment is supported to ensure the smooth progress of the scrubbing operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com