A fire hose automatic cleaning reel device

An automatic cleaning and fire hose technology, applied in fire rescue and other directions, can solve the problem that the hose cannot be cleaned, and achieve the effect of sufficient and complete cleaning, good cleaning effect and good brushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

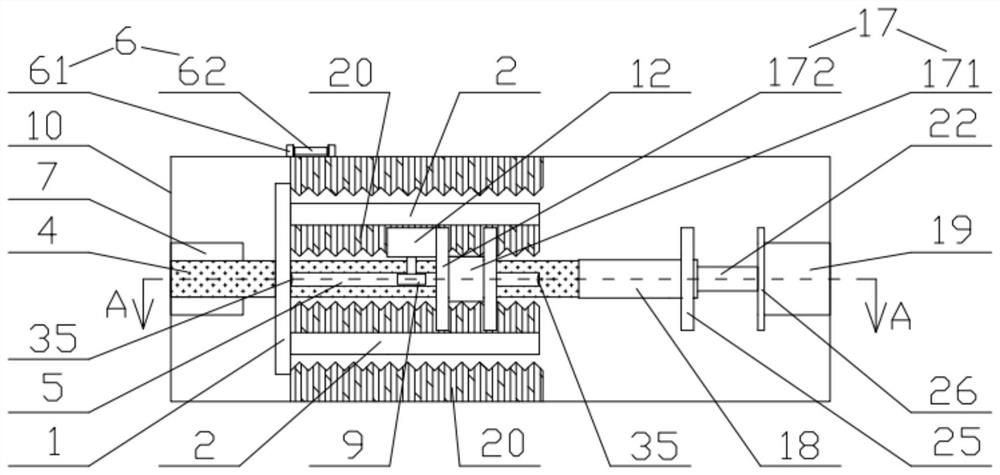

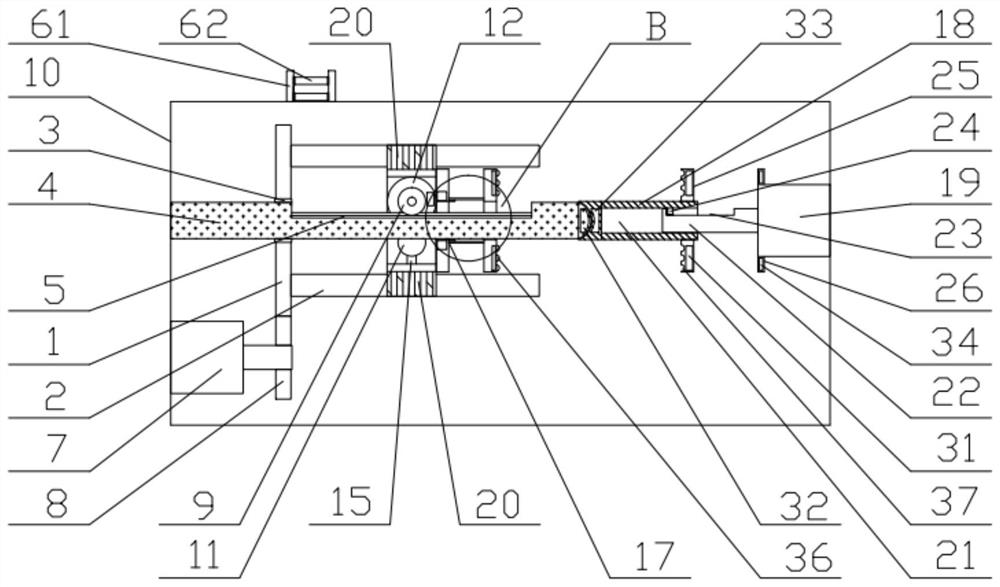

[0034] likefigure 1 and figure 2 A fire hose automatic cleaning reel device shown includes a box body 10 containing water inside. The box body 10 is provided with a cleaning mechanism and a reel mechanism. The cleaning mechanism includes a shaping component, a walking component and a cleaning mechanism. Brush 20;

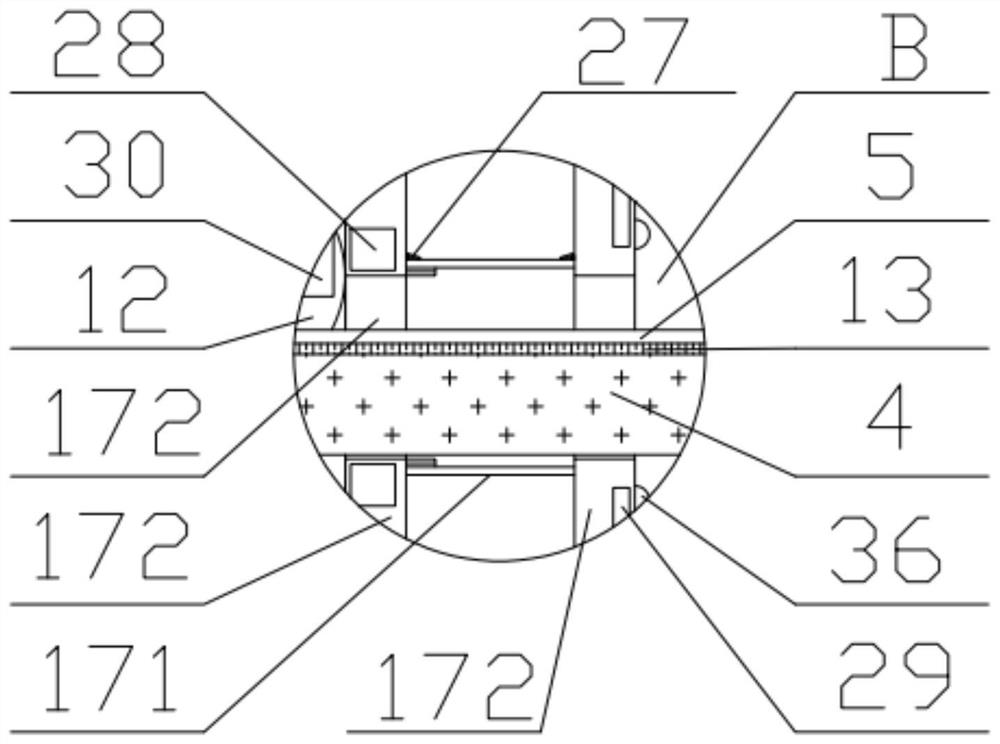

[0035] Described sizing assembly comprises rotating disk 1 and at least three winding rods 2 (such as Figure 5 As shown, three winding rods 2) are provided in this embodiment, and a perforation is provided at the center of the turntable 1, and a fixed shaft 4 is connected to the perforation through a bearing 3 in the perforation, and the fixed shaft 4 is wound on its back. One end of the side where the rod 2 is located is fixed on the inner wall of one end of the box body 10, and the part of the fixed shaft 4 corresponding to the winding rod 2 is provided with a running groove 5 parallel to the axial direction of the fixed shaft 4, and the walking assembly is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com