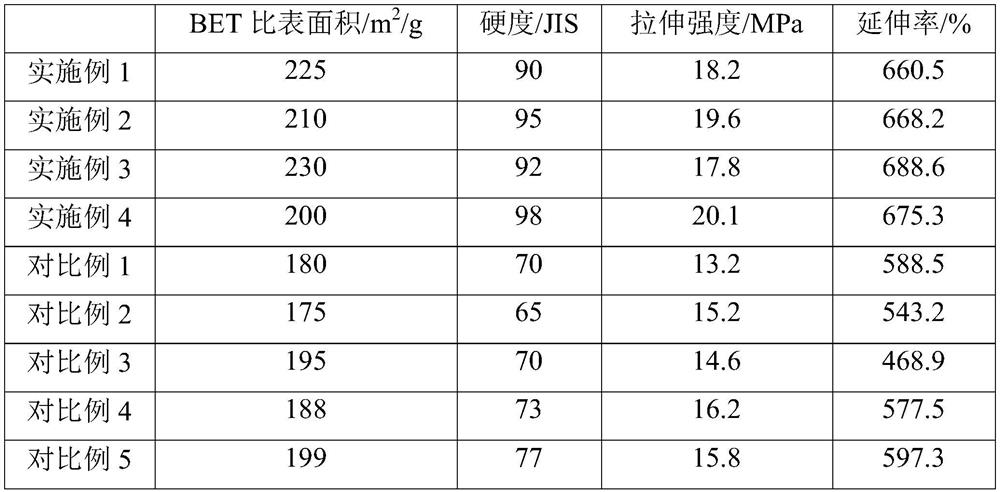

Preparation method and application of white carbon black for reinforcement

A white carbon black and reinforcement technology, applied in the field of white carbon black, can solve problems such as poor reinforcement performance and small specific surface area, and achieve the effects of improving mechanical properties, improving reinforcement performance, and strengthening reinforcement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a preparation method of white carbon black for reinforcement, the preparation method comprising the following steps:

[0042] (1) carry out the first treatment after mixing the water glass solution and the first treatment liquid to obtain a slurry;

[0043] (2) performing the second treatment after mixing the slurry obtained in step (1) with the second treatment liquid, and obtaining the white carbon black for reinforcement through solid-liquid separation;

[0044] The modulus of the described water glass solution of step (1) is 1.7; Described the first processing liquid comprises chloroacetic acid and ammonium citrate; The mol ratio of chloroacetic acid and ammonium citrate is 1:0.4 in the described first processing liquid; The volume ratio of the water glass solution and the first treatment liquid is 1:2.5; the first treatment is carried out under a protective atmosphere; the gas of the protective atmosphere includes carbon dioxide gas; the vo...

Embodiment 2

[0048] This embodiment provides a preparation method of white carbon black for reinforcement, the preparation method comprising the following steps:

[0049] (1) carry out the first treatment after mixing the water glass solution and the first treatment liquid to obtain a slurry;

[0050] (2) performing the second treatment after mixing the slurry obtained in step (1) with the second treatment liquid, and obtaining the white carbon black for reinforcement through solid-liquid separation;

[0051] The modulus of the described water glass solution of step (1) is 2; Described the first processing liquid comprises chloroacetic acid and ammonium citrate; The mol ratio of chloroacetic acid and ammonium citrate is 1:0.5 in the described first processing liquid; The volume ratio of the water glass solution and the first treatment liquid is 1:2; the first treatment is carried out under a protective atmosphere; the gas of the protective atmosphere includes carbon dioxide gas; the volume...

Embodiment 3

[0055] This embodiment provides a preparation method of white carbon black for reinforcement, the preparation method comprising the following steps:

[0056] (1) carry out the first treatment after mixing the water glass solution and the first treatment liquid to obtain a slurry;

[0057] (2) performing the second treatment after mixing the slurry obtained in step (1) with the second treatment liquid, and obtaining the white carbon black for reinforcement through solid-liquid separation;

[0058] The modulus of the described water glass solution of step (1) is 1.5; Described the first processing liquid comprises chloroacetic acid and ammonium citrate; The mol ratio of chloroacetic acid and ammonium citrate is 1:0.5 in the described first processing liquid; The volume ratio of the water glass solution and the first treatment liquid is 1:3; the first treatment is carried out under a protective atmosphere; the gas of the protective atmosphere includes carbon dioxide gas; the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com