A detonating cord fixing device for a high-voltage transmission line

A technology for high-voltage transmission lines and high-voltage transmission lines, which is applied in the installation of cables, overhead installations, electrical components, etc., can solve the problems of deicing failure, deformation of transmission towers, and excessive stretching of transmission lines, and achieves simple, practical, and high-quality installations. Mechanical reliability, small diameter requirements

Active Publication Date: 2022-05-31

SHANDONG UNIV

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In some rainy and snowy or humid suburban areas, rime, rime, and ice coating often appear on the distribution lines. If the rime, rime, and ice coating that have solidified on the line have accumulated It will continue to increase, and eventually the transmission line will be overstretched, the relevant circuit components will be worn out, and even the transmission tower will be deformed, unstable and collapsed, and the adjacent transmission tower will be continuously damaged, causing serious damage to the power grid and affecting the economic development of the power transmission place. , social operation and normal life have a major impact

[0004] However, such severe electrical accidents caused by transmission line consolidation are not inevitable

At present, in order to deal with the problem, two methods are generally used for deicing. The first method is that relevant personnel climb on the transmission tower to carry out high-altitude operations, and use deicing tools and corresponding protective measures to manually deicing. This method is the most direct, but During the deicing process, because the transmission lines and transmission towers will be covered with rain and snow, it is very easy to affect the reliability of the safety equipment in the manual deicing process, and it poses a severe test to the life safety of personnel working at heights, and this kind of The labor cost required by the method is relatively expensive; the second is to use some thermal deicing facilities such as thermal deicing vehicles, thermal deicing robots, etc., to use electric energy to generate heat to melt the ice and snow solidification on the transmission line, so that However, this method will be affected by factors such as terrain and icing length. Many large-scale thermal deicing facilities cannot be specifically applied because of the harsh geographical environment such as plateaus, hills or cliffs where overhead transmission lines are located. Moreover, some thermal deicing robots with good performance fail to deice because the internal battery energy storage is not enough to remove the solidification of long ice-coated lines, which wastes a lot of energy. It is not recommended to use them in the current environment of energy shortage.

[0005] At present, there is a method of blasting deicing, which overcomes the defects of the above two methods. It needs to use a fixing device to fix the detonating cord under the high-voltage transmission line. When the ice layer of the high-voltage transmission line reaches the set thickness, Using the detonation index blasting blasting device, using vibration to de-ice, but the inventor found that the current detonating cord fixing device cannot meet the use requirements of high-voltage transmission lines with different diameters, and the distance between the high-voltage transmission line and the detonating cord cannot be adjusted , unable to meet the blasting deicing requirements in complex environments

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0037] The shell 7 adopts a sheet metal shell, and the bottom end of the shell 7 is fixed on the top of the fixing member 1 .

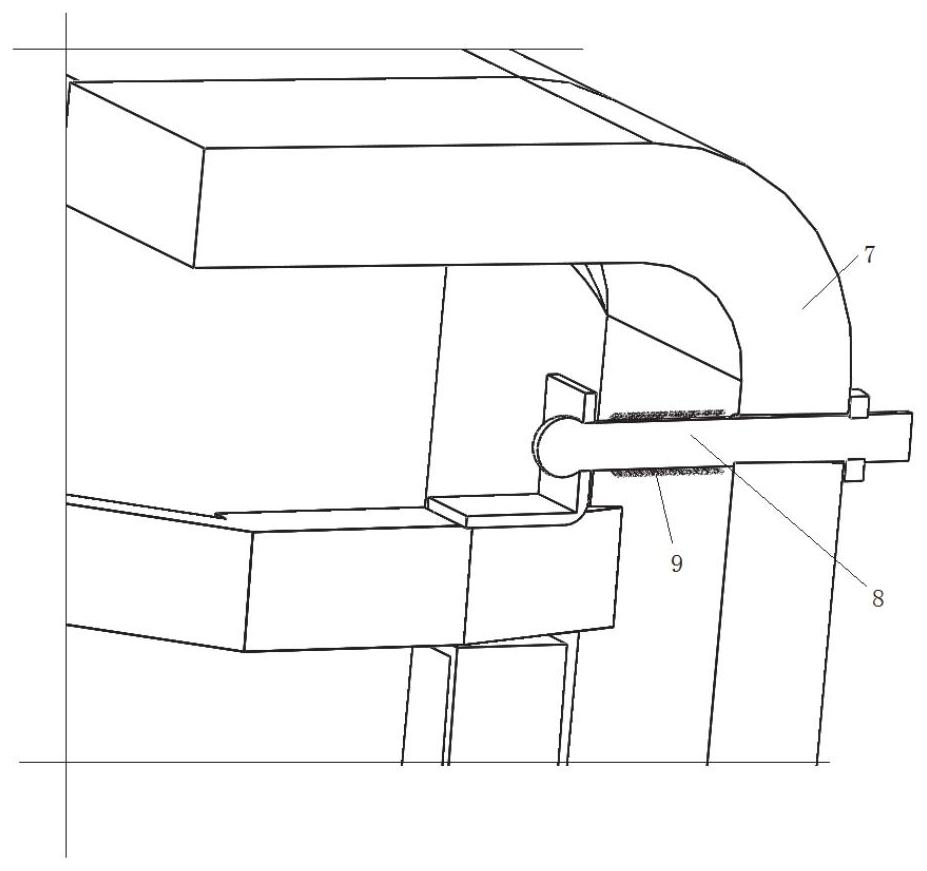

[0038] The structures of the first elastic component and the second elastic component are the same, and the first elastic component is taken as an example to illustrate,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

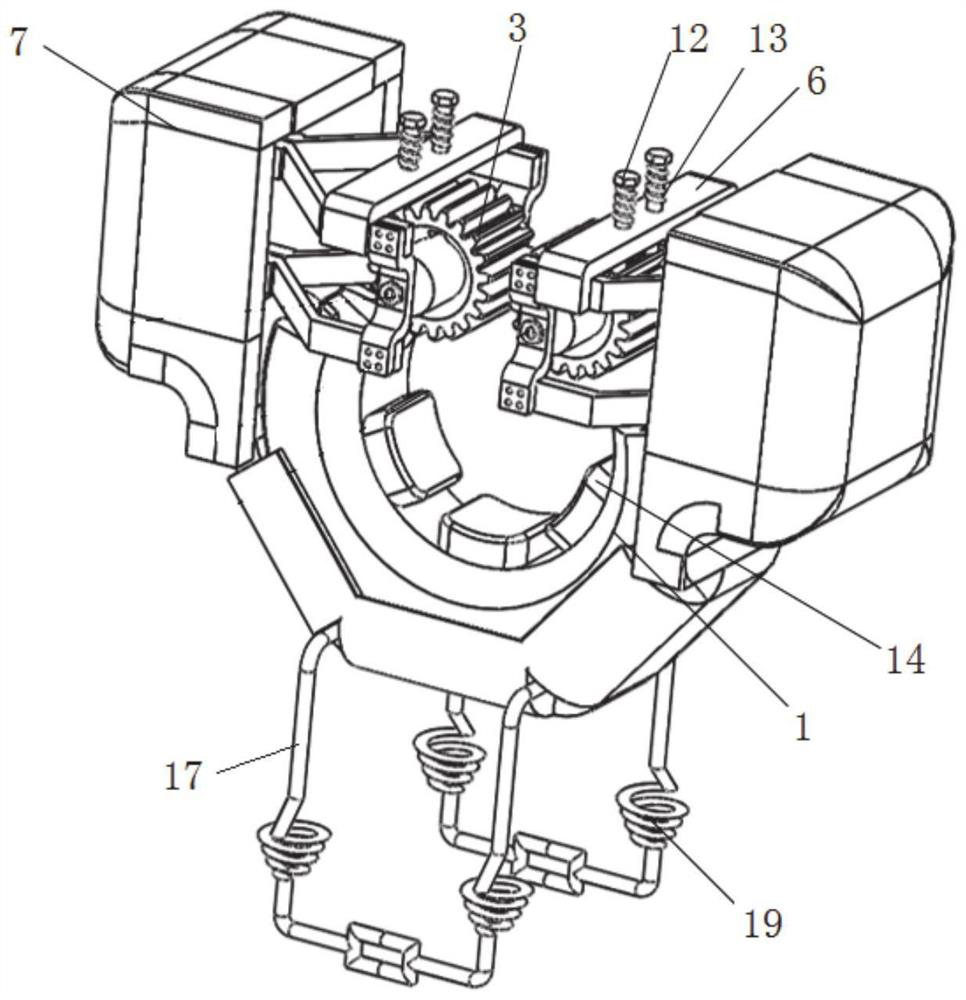

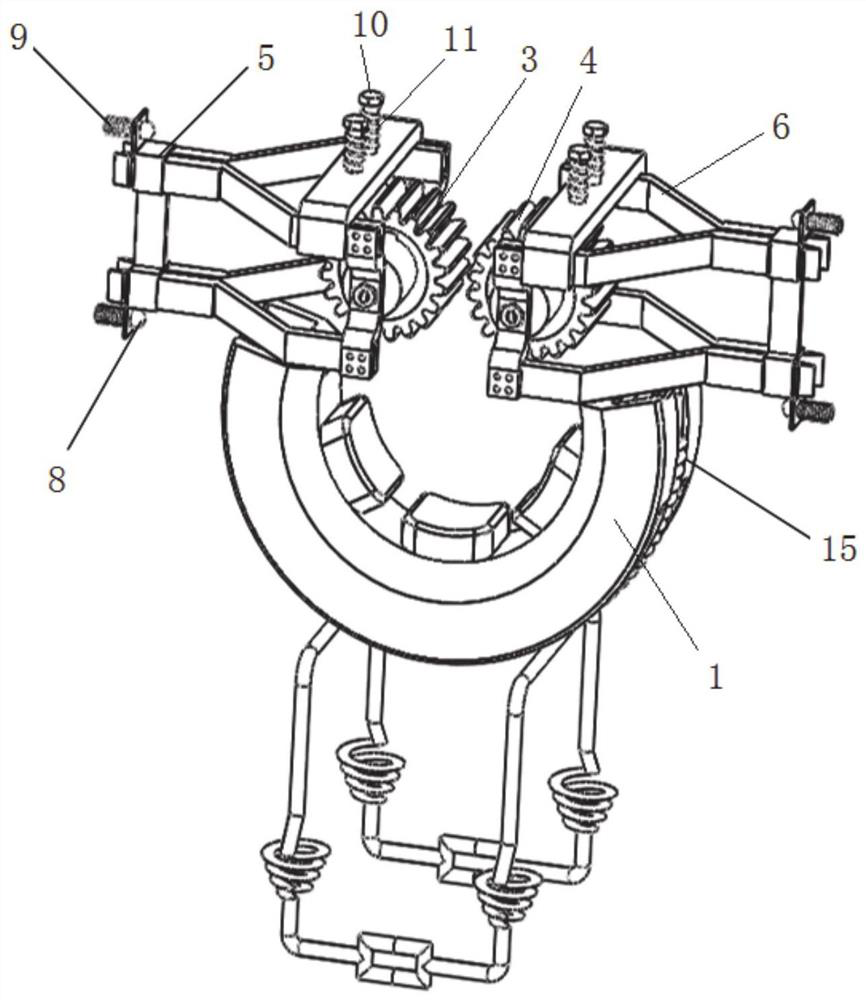

The invention relates to a detonating cord fixing device for a high-voltage transmission line, which includes a fixing part, the fixing part is provided with a space for accommodating a high-voltage transmission line, and a first gear and a second gear that can move toward or away from each other are arranged above the fixing part. The first gear is elastically connected to the shell through the first frame, the second gear is elastically connected to the shell through the second frame, the shell is fixed on the top of the fixture, and the top of the first frame is elastically connected with teeth that can be inserted into the adjacent teeth of the first gear Between the first locking piece, the top of the second frame body is elastically connected with the second locking piece that can be inserted between the adjacent teeth of the second gear, and the bottom of the fixing piece is provided with a detonating cord fixing element. The fixing element of the present invention The device meets the requirement of fixing detonating cords under high-voltage transmission lines with different diameters.

Description

A high-voltage transmission line detonating cord fixing device technical field The present invention relates to overhead transmission line blasting and deicing technical field, be specifically related to a kind of high-voltage transmission line detonating cord Fixtures. Background technique [0002] The statements herein merely provide background related to the present invention and do not necessarily constitute prior art. [0003] In some rainy and wet suburban areas, rain and rime often appear on the transmission lines where it is distributed. As well as icing and other conditions, if the rain, rime and icing that have been consolidated on the line will continue to accumulate after a long time increase, and eventually the transmission line will be overstretched, the related circuit components will be worn out, and even the transmission tower will be deformed, unstable and collapsed. The adjacent transmission towers are continuously damaged, causing serious grid damag...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02G7/16

CPCH02G7/16

Inventor 张建华卜杨胡向义赵赫

Owner SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com