High-precision flexible piezoelectric film material local polarization method

A technology of flexible piezoelectric and thin-film materials, which is applied in the manufacture/assembly of piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive devices, circuits, etc. problems such as low electrical properties, to achieve the effect of good polarization stability and high polarization piezoelectric coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention is further illustrated in conjunction with the accompanying drawings and examples.

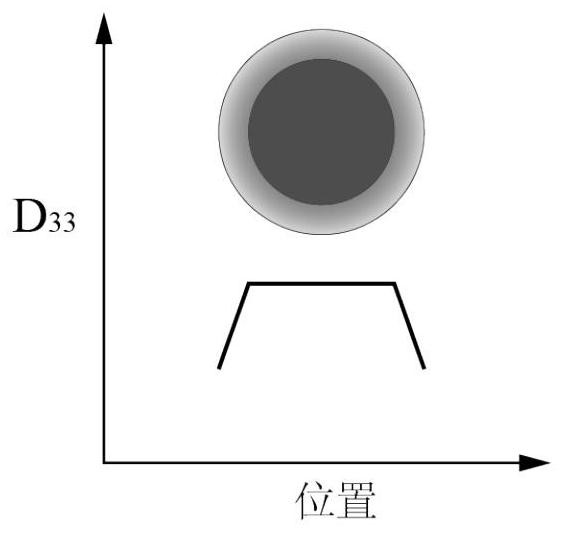

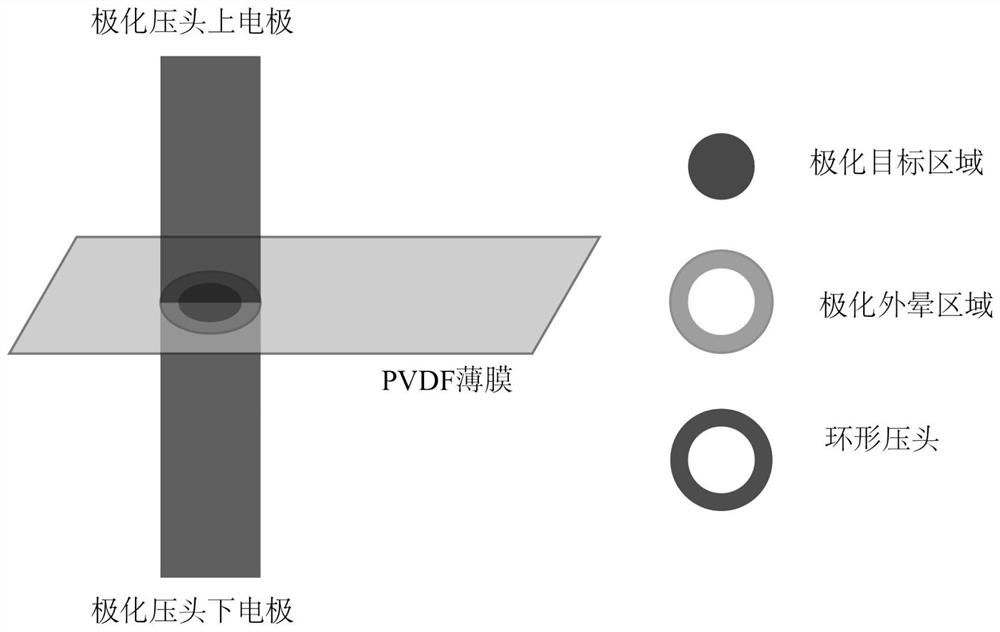

[0025] The present invention employs a topically polarization process, a gradient DC voltage is loaded with a gradient DC voltage.

[0026] Local polarization method of high precision flexible piezoelectric film material, including the steps of:

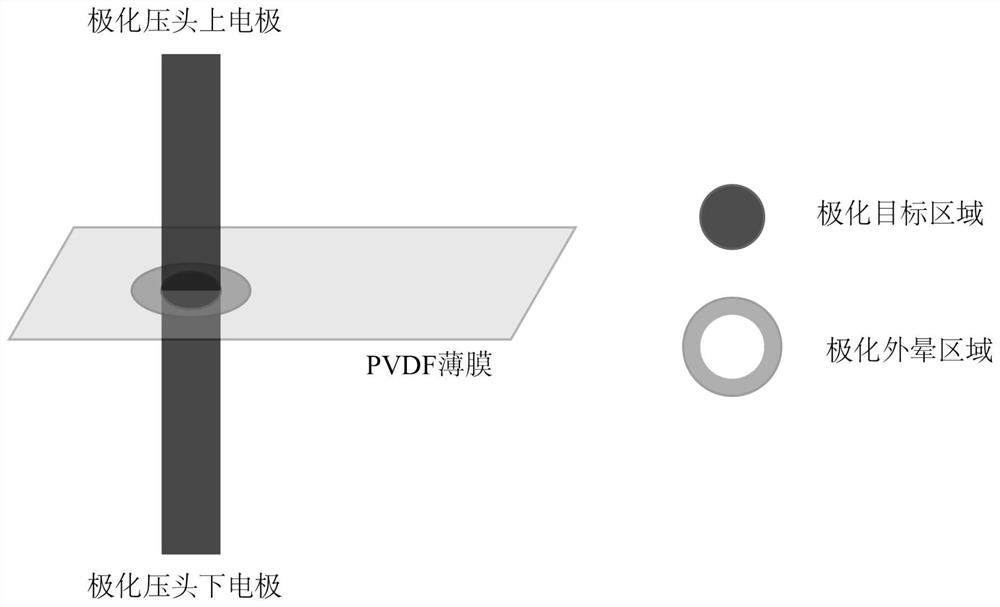

[0027] Step 1: Using the local polarization process, the flat electrode polarized indenter is used as the upper and lower electrode polarized indenter, and the film is pressed against the film on the film, and there is no additional external force;

[0028] Step 2: Divide the film into a, b, first A plane contact positive electrode, the B-plane contact negative electrode, loading 2 minutes for the initial voltage at 500V;

[0029] Step 3: Invert the film, the B-plane contact the positive electrode, and the negative electrode is contacted, and the 500V voltage is loaded for 2 minutes; during alternately loading, the film is in turn. U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com