Filter screen, range hood and cooking fume filtering method

A range hood and oil fume filtering technology, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problem of affecting the air volume of the range hood and the effect of the range hood, reducing the performance of the range hood, increasing the resistance of the flue, etc. problems, to achieve the effect of improving user experience, low noise, and improving purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] The filter screen in this embodiment can be applied in various filtering products. During application, the filter screen is installed in the filter channel of the corresponding filter product. When the filter screen is used in an air cleaner, the filter screen is installed in the air filter. within the flow channel. When the filter screen is used in a range hood, the filter screen is installed in the range hood's fume passage.

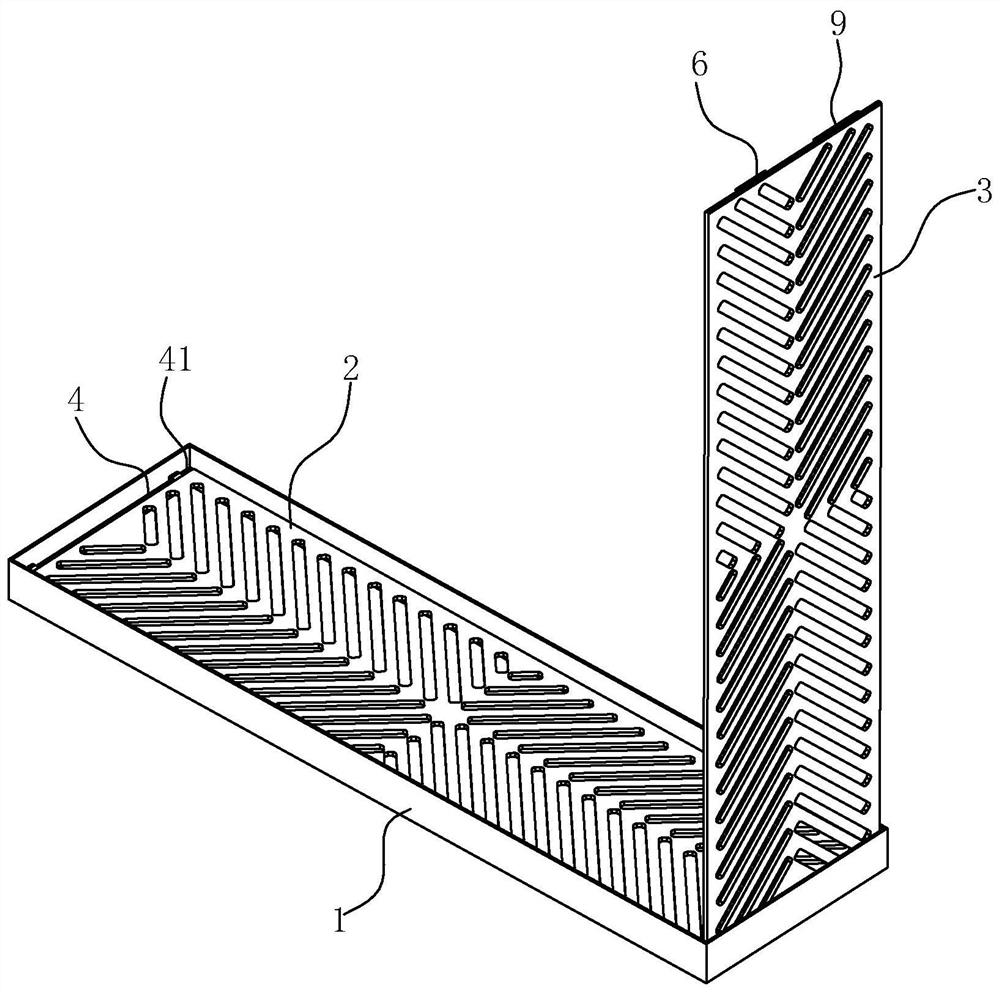

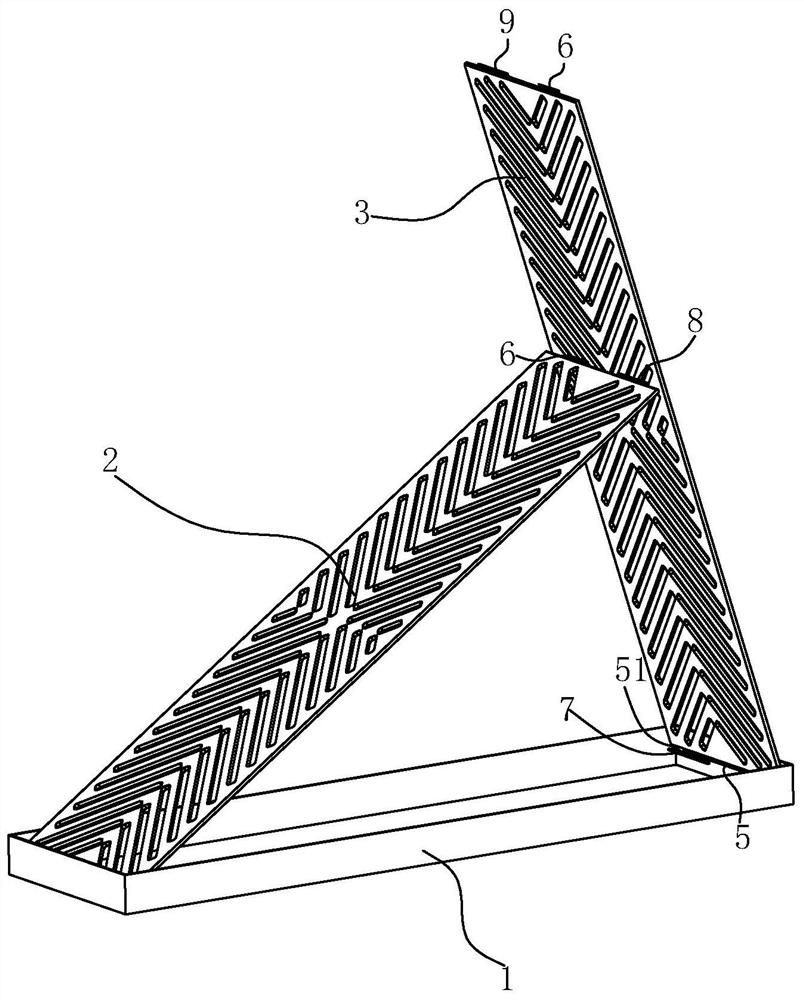

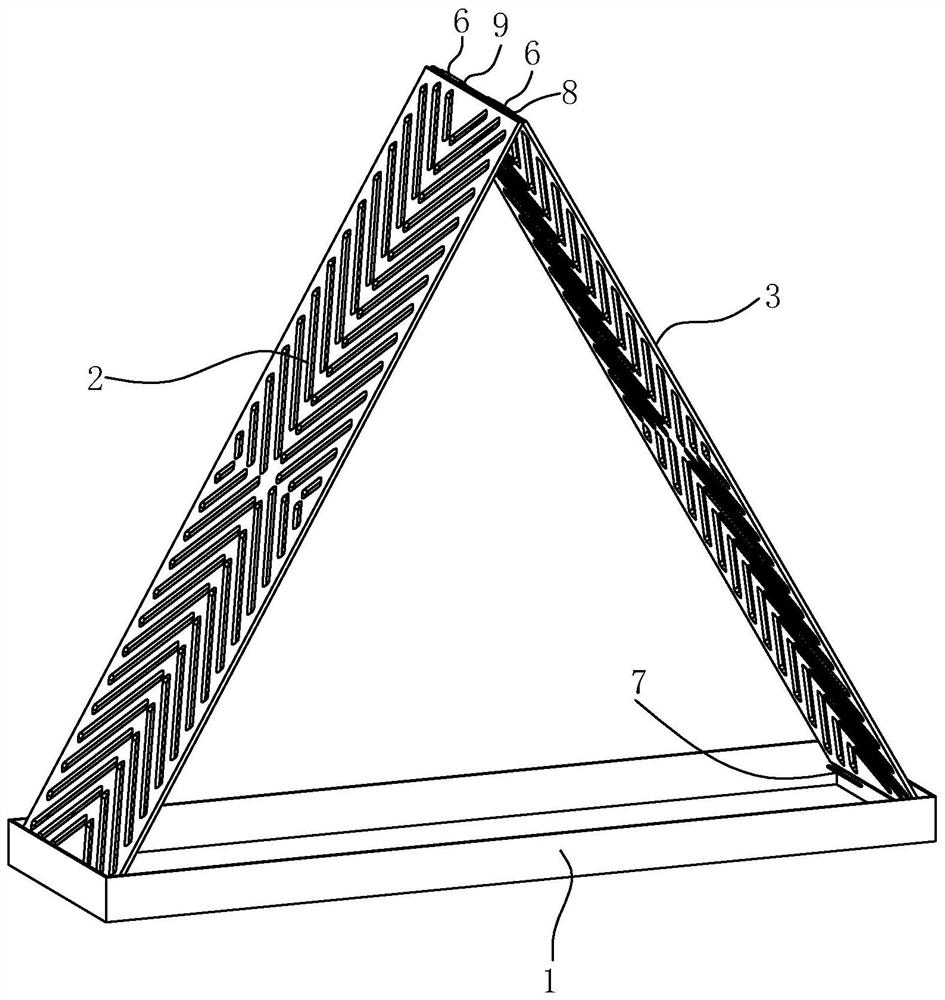

[0034] Such as Figure 1 to Figure 4 As shown, the filter includes a frame 1, a first filter 2, a second filter 3 and a driving mechanism. The frame 1 is surrounded by frame strips, and then the flow surface of the frame 1 is formed in the middle. The shape of the flow surface is the same, so that the areas of the first filter screen 2 and the second filter screen 3 match the area of the flow surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com