Construction device and method of roadway composite beam support system

A technology of construction device and construction method, which is applied in the direction of tunnel, shaft equipment, installation of anchor rods, etc., can solve the difficulties in meeting the construction efficiency and safety requirements of composite beam support, the mismatch of anchor cable drilling holes, and the time-consuming installation of anchor cables To achieve the effect of facilitating the installation of anchor cables, saving workers' physical strength and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

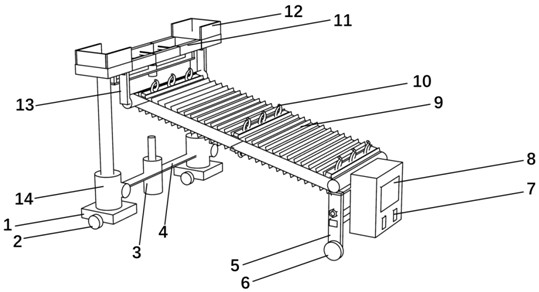

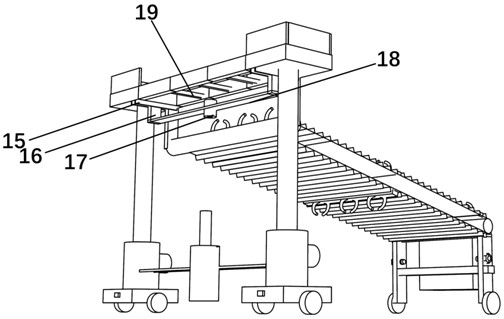

[0030] In a typical embodiment of the present disclosure, such as Figure 1-Figure 2 As shown, a construction device for the roadway composite beam support system is given.

[0031] Aiming at the problems of low efficiency and poor safety in roadway composite beam support at present, the composite beam is installed through the construction device of the roadway composite beam support system, and the composite beam is supported by the first bracket located in front, and the conveying mechanism 9 Establish the connection relationship between the high position of the composite beam and the low position of the second support at the rear, use the drilling rig 3 and the tensioner 17 to complete the drilling and anchor cable tensioning work, reduce the installation difficulty of the composite beam, and improve the construction of the composite beam in the roadway efficiency and safety.

[0032] The construction device of the roadway composite beam support system mainly includes the ...

Embodiment 2

[0065] In another embodiment of the present disclosure, as Figure 1-Figure 2 As shown, a construction method of roadway composite beam support system is given.

[0066] Utilize the roadway composite beam support system construction device in embodiment 1, comprise the following steps:

[0067] Place the combined beam on the top surface of the supporting plate 11, the lifting frame 14 lifts the supporting plate 11 and the combined beam to the support position, and simultaneously drives one end of the conveying mechanism 9 to rise, and the second support 5 moves with the other end of the conveying mechanism 9;

[0068] The drilling rig 3 passes through the support plate 11 to drill holes in the composite beam and the surrounding rock, and the anchor cable clamp 10 carries the anchor cable and transports it to the anchor cable tensioner 17;

[0069] During the drilling process, the position of the drilling rig 3 is adjusted to drill holes in multiple set positions of the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com