A Pile Top Rigidity Adjusting Device Based on Variable Strength Supporting Materials

A technology of adjusting device and changing strength, applied in the field of foundation foundation, can solve the problems of complex preparation process, low adjustment precision, easy corrosion of supporting members, etc., and achieve the effects of simple preparation process, high adjustment precision and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

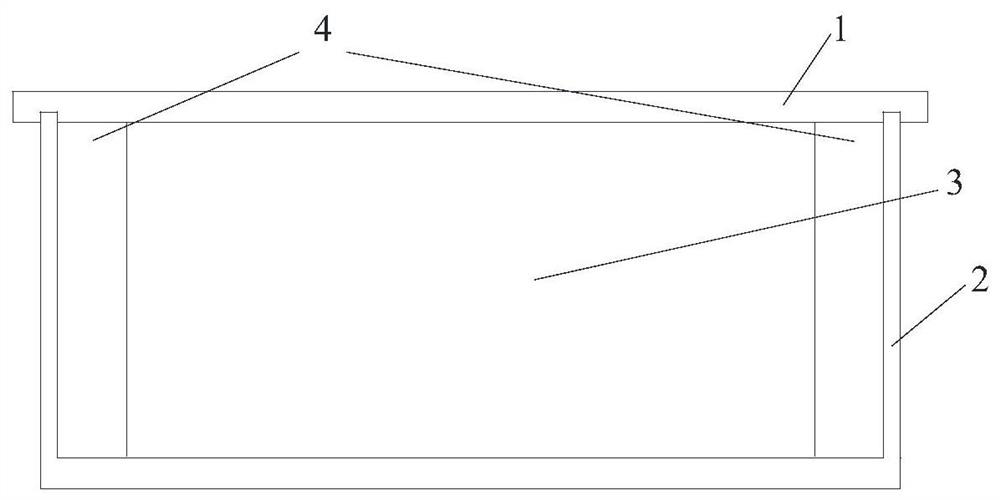

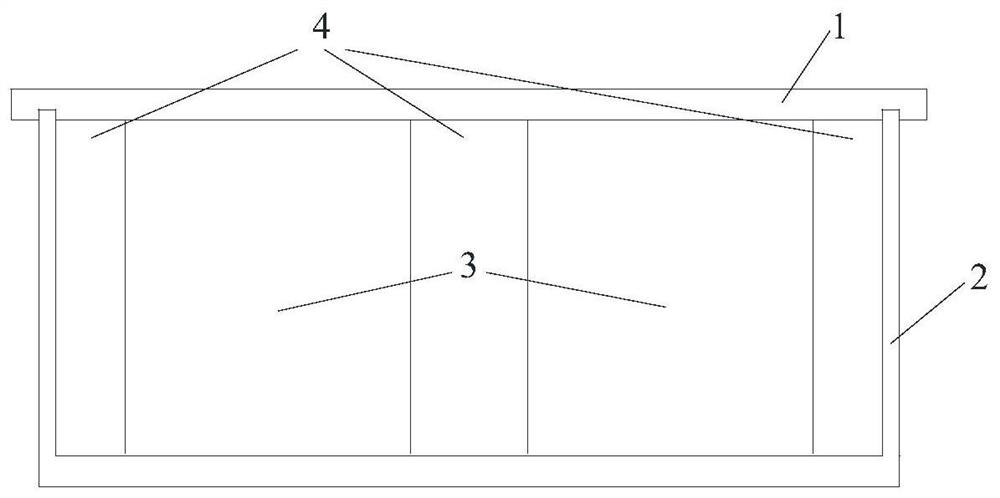

[0066] A pile top stiffness adjustment device, such as figure 1 , figure 2 As shown, it includes a cover plate 1 , a cylinder block 2 , a variable-strength metal support material 3 and a buffer material 4 . The cylinder block 2 is in the form of an upper opening and a lower sealing structure. The cover plate 1 is installed on the upper part of the cylinder block 2. The variable-strength metal supporting material 3 stands inside the cylinder block 2, and the buffer material 4 fills the internal gap of the rigidity adjusting device.

[0067] The variable-strength metal support material 3 uses the difference in appearance parameters to change its own compression performance, thereby further improving the existing pile top stiffness adjustment device, overcoming the existing pile top stiffness adjustment device. The disadvantages of vertical displacement caused by the crushing or discharge of materials, high adjustment accuracy, stable operation, simple preparation process and l...

Embodiment 2

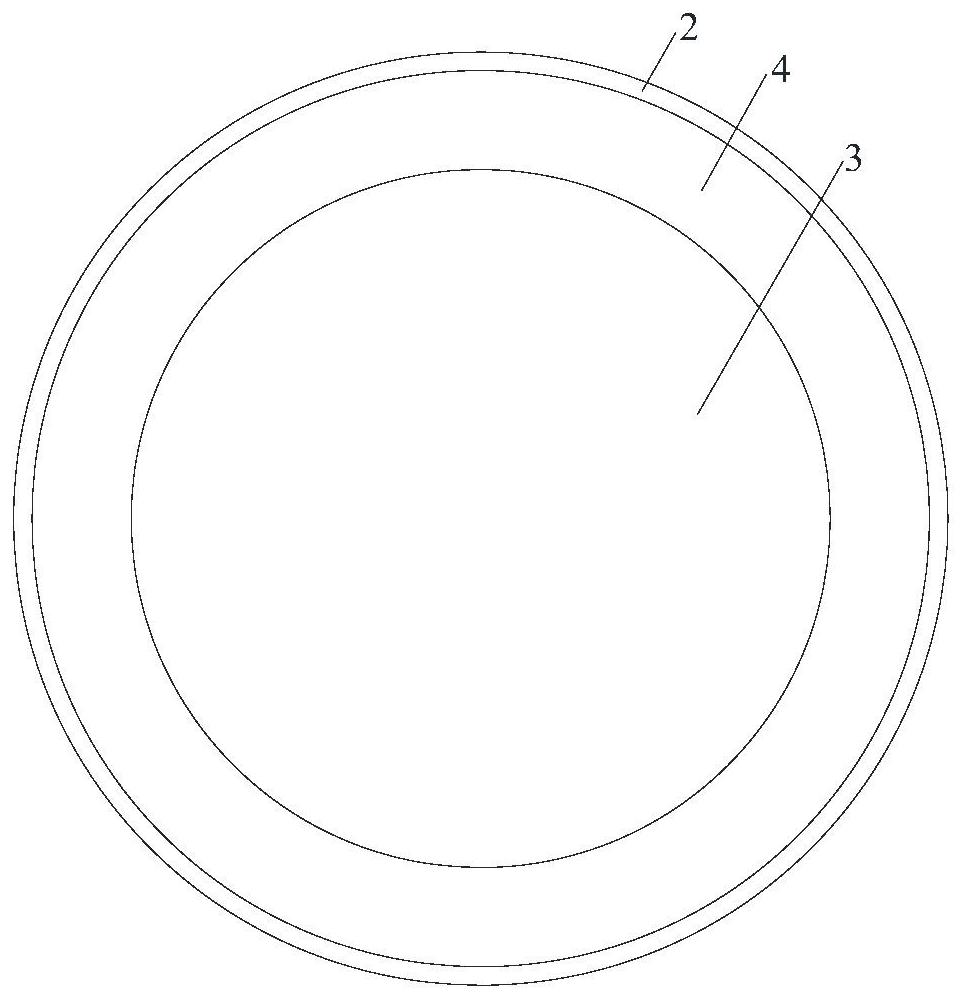

[0085] The difference from Embodiment 1 is the shape of the variable-strength metal support material 3, such as image 3 , Figure 4 shown. The variable-strength metal support material 3 is foamed metal, and the shape is a hollow cylinder. The height of the hollow cylinder is 120mm, the upper section diameter is 200mm, and the inner diameter is 60mm.

Embodiment 3

[0087] The difference from Embodiment 1 lies in the shape of the variable-strength metal support material 3, such as Figure 5 shown. The variable-strength metal supporting material 3 is foamed metal, and the shape is a truncated cone. The height of the truncated cone is 120 mm, the diameter of the upper section is 150 mm, and the diameter of the lower section is 250 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com