Winding machine and method for winding a fibrous web onto a winding core

A fiber web, winder technology, applied in the field of winder and for winding fiber web onto the core, which can solve the problems of high running cost, high air consumption, poor function, etc., and achieve good linearity The effect of strength, cheap manufacture, and good function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

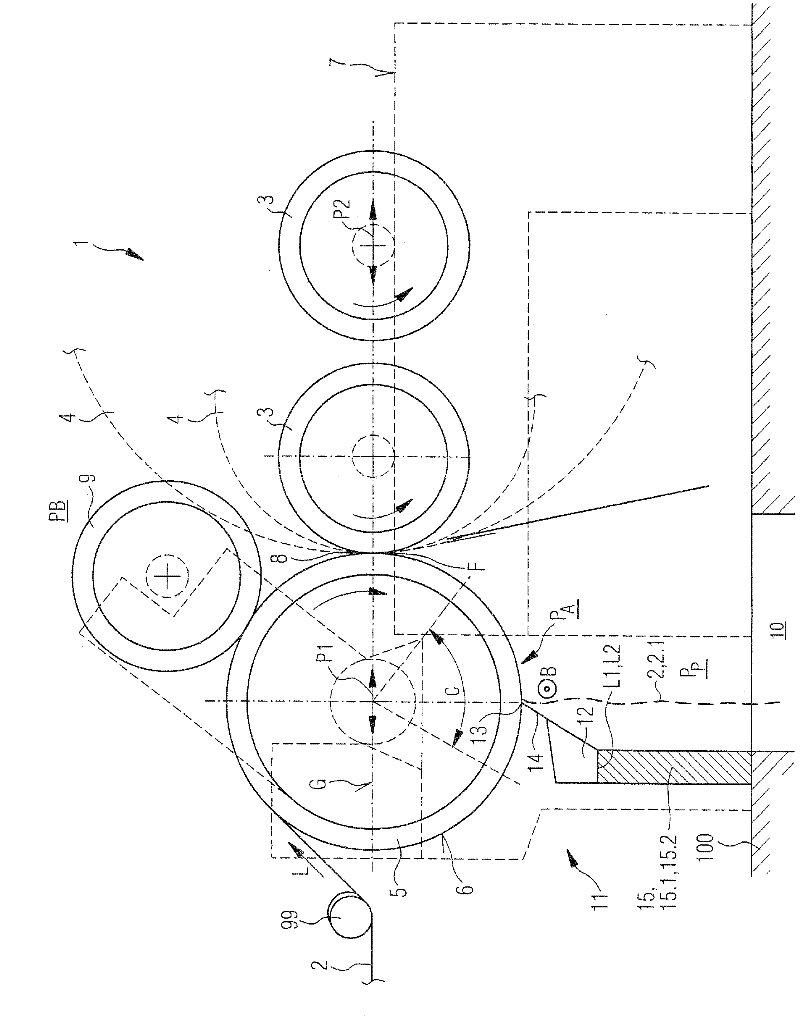

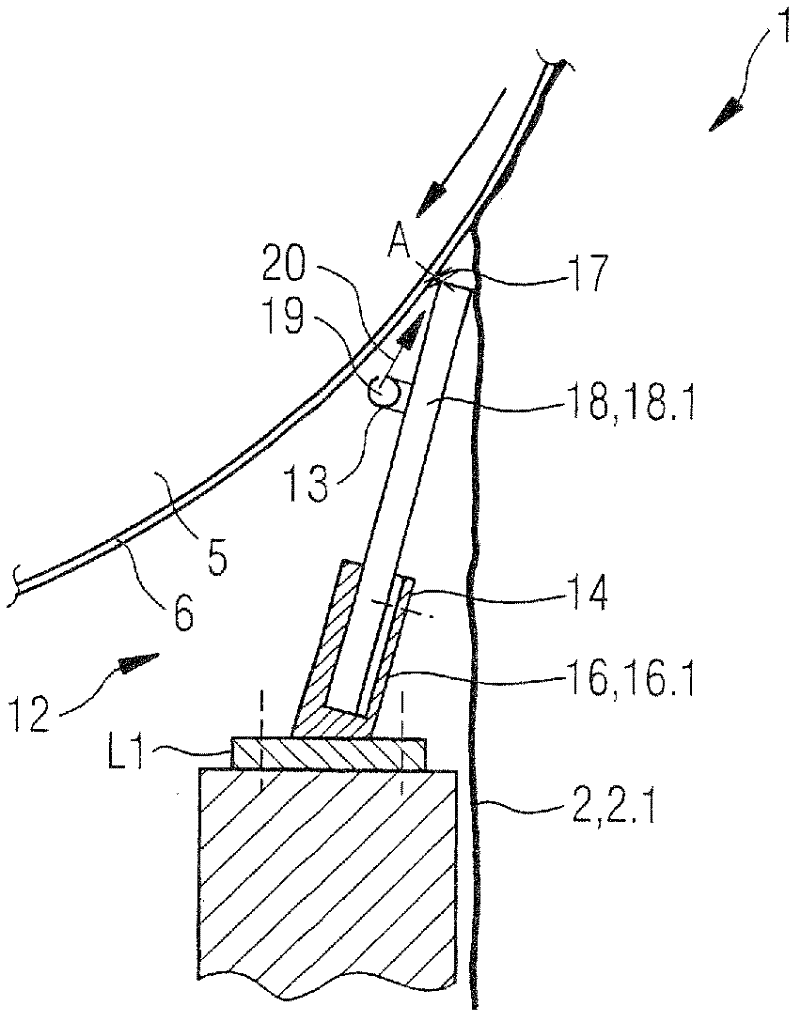

[0042] figure 1 Shown in a schematic side view is a winder 1 for winding a fiber web 2 onto a mandrel 3 into a reel 4 shown only in dashed lines, in particular empty or partially Winding core. The fibrous web 2 may in particular be a fibrous web, such as a paper, cardboard or tissue web.

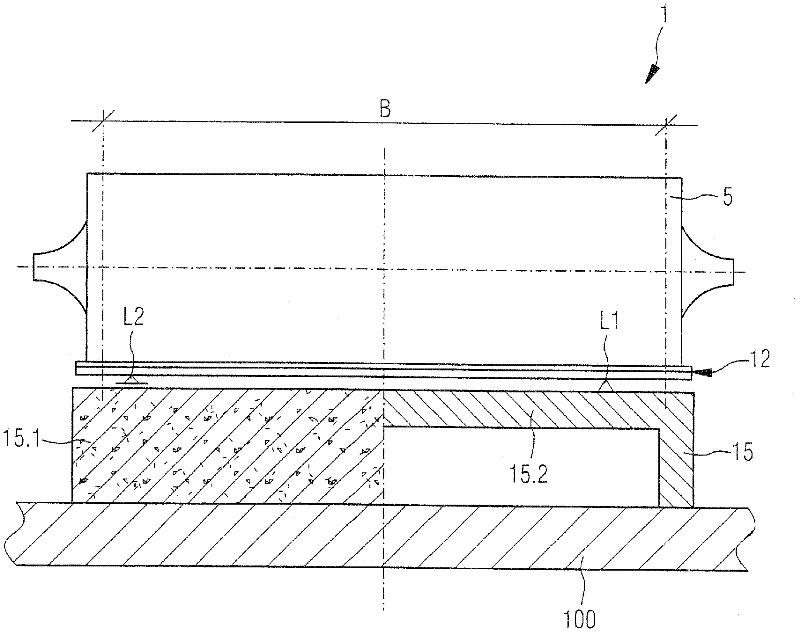

[0043] The winder 1 placed on the hall floor 100 comprises a carrying drum 5 , which is also called a pressure drum or a support roll in the professional field, and around which the fibrous web 2 is wound in sections, the carrying drum 5 is either rigidly supported , can either be moved along an imaginary horizontal line G indicated by a dotted line by means of a not shown slider device or a pressing device (double arrow P1 ) and generally driven by a not shown drive. Various bearings and types of movement for the carrier roller 5 are disclosed in particular in German laid-open publication DE 19807897 A1; the content of this publication with respect to the various types of bearings and mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com