Horizontal supporting system and construction method thereof

A horizontal support and system technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of increasing the cost of foundation pit construction and the installation cost of fish belly beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

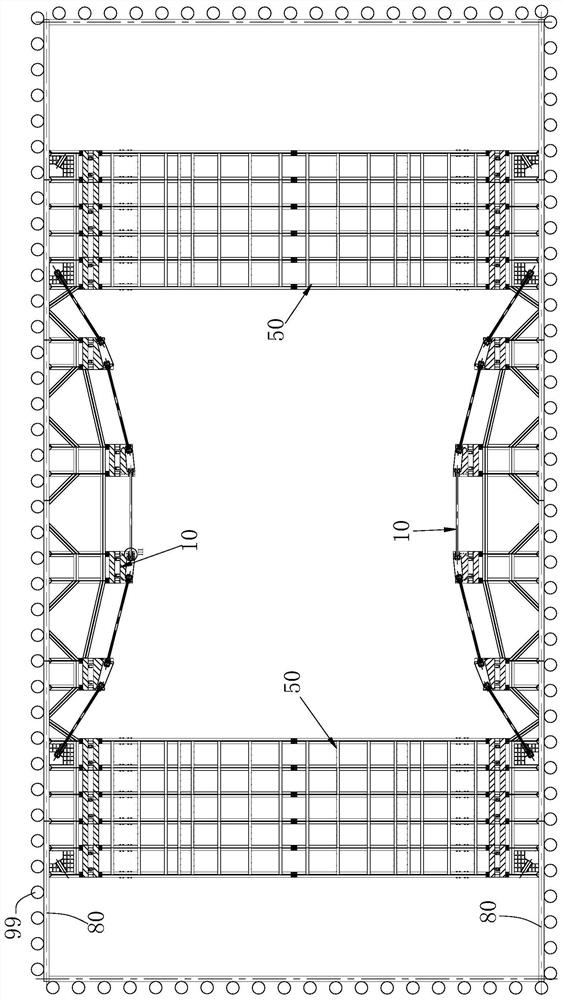

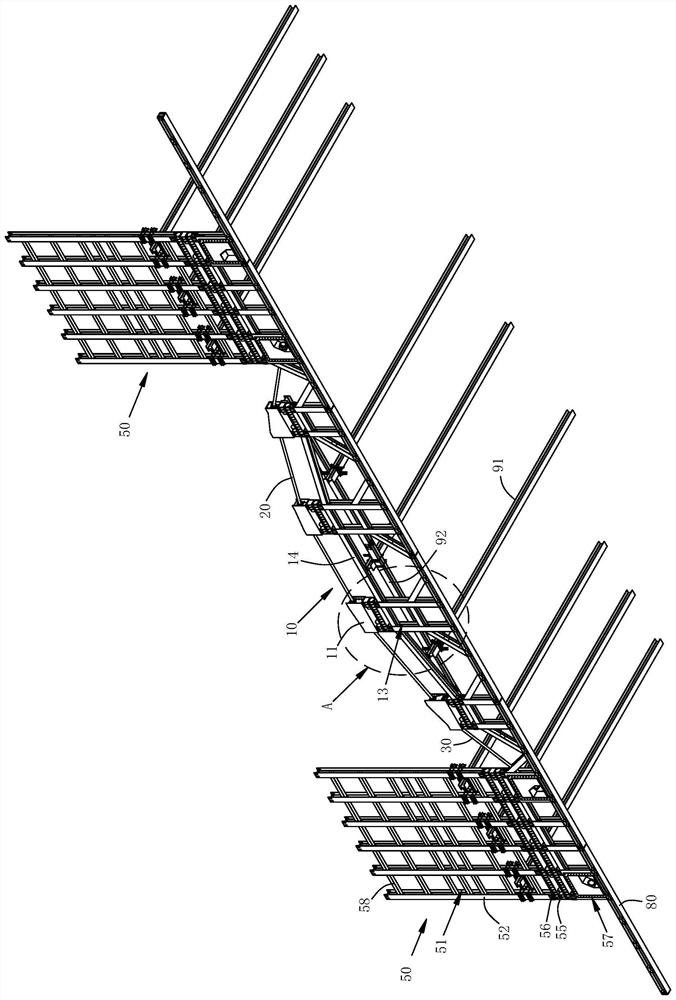

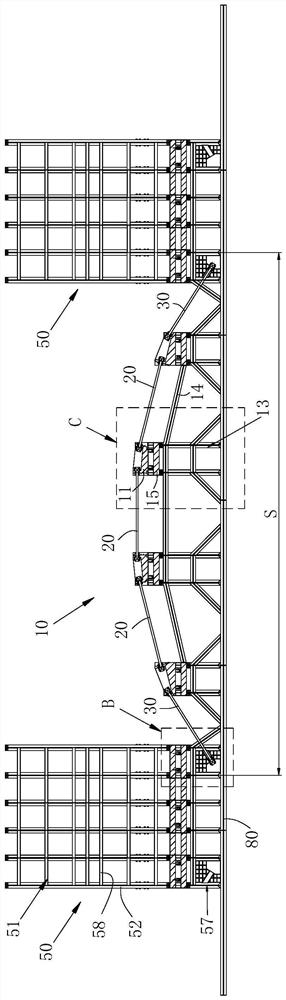

[0039] see Figure 1-Figure 7 , the horizontal support system will be described first below.

[0040] In this embodiment, the horizontal support system is arranged in the foundation pit. The foundation pit is rectangular and has two parallel long sides. The horizontal support system includes two fish-belly beams 10 and two horizontal beams 50 . A fish-belly beam 10 is arranged on each long side of the foundation pit, two horizontal beams 50 are arranged in parallel, and the two ends of each horizontal beam abut against one long side respectively. In this embodiment, the span S of each fish-belly girder is 38 meters.

[0041] Each fishbelt beam 10 includes a waist beam 80 installed on the support pile 99 and a support frame group installed on the waist beam 80. In this embodiment, the support frame group includes four support frames 13, the four The support frames 13 extend in the same direction along the horizontal direction and are all perpendicular to the waist beam 80. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com