Shape fixing and keeping method for polypropylene co-mixing infusion bag

An infusion bag, polypropylene technology, applied in the field of medical devices, can solve problems such as sterilization pressure control mode and parameter mismatch, and achieve the effect of avoiding shape interference, preventing bag shrinkage, and neat shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

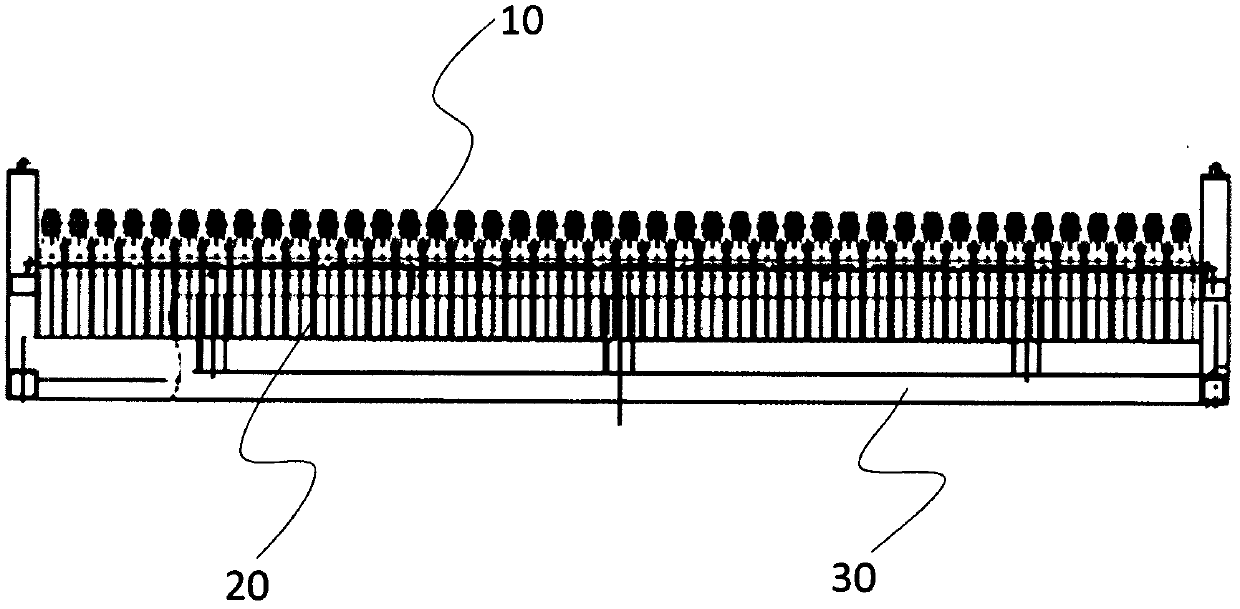

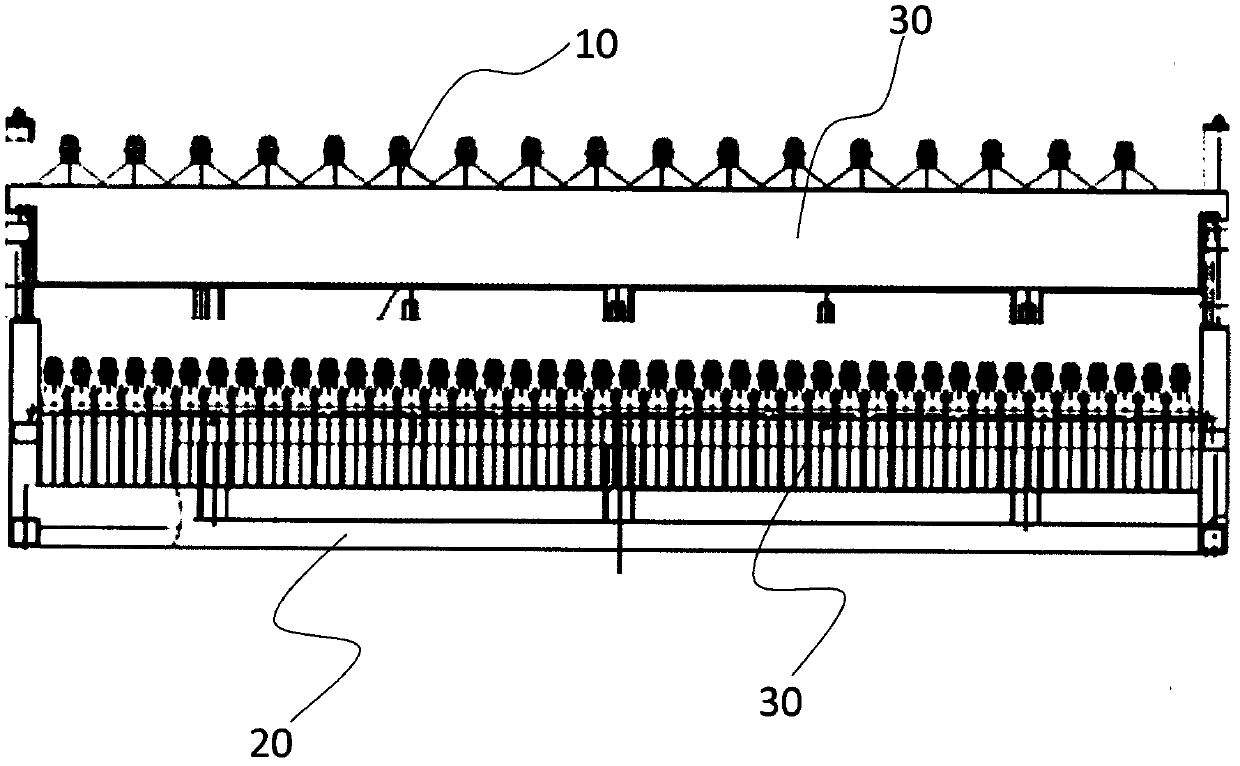

Image

Examples

Embodiment 1

[0029]500ml sodium chloride injection

[0030] (1) The temperature of the filling liquid is 48°C;

[0031] (2) adopt the vertical loading mode of the present invention;

[0032] (3) The sterilization temperature is 121°C, the sterilization time is 12 minutes, and the sterilization pressure is 0.19MPa; the sterilization starts at 13:21, and when the sterilization temperature reaches 121°C, the pressure reaches 0.19Mpa and heat preservation and pressure extinguishing Sterilize for 12 minutes, and the pressure in the heat preservation stage is maintained at 0.19MPa. After the completion, the pressure in the sterilizer will decrease with the temperature drop. cabinet;

[0033] (4) After sterilization, the product is full, the bag shape is uniform, and the transparency is high. The pressure inside the bag has been tested to be between 0.008-0.013MPa, which improves the ability of the bag to resist external pressure and ensures that the shape of the bag does not deform.

Embodiment 2

[0035] 100ml: glucose injection

[0036] (1) The temperature of the filling liquid is 63°C;

[0037] (2) adopt the vertical loading mode of the present invention;

[0038] (3) Sterilize with a sterilization temperature of 121°C, a sterilization time of 12 minutes, and a pressure of 0.21MPa; the sterilization starts at 10:09, and when the sterilization temperature reaches 121°C, the pressure reaches 0.21MPa and starts to maintain pressure Sterilize for 12 minutes, and the pressure in the heat preservation stage is maintained at 0.21MPa; after completion, the pressure in the sterilizer decreases with the temperature drop, and when the temperature drops to 50°C, it drops to 0.13MPa and starts to release the pressure. At 11:37, the pressure drops to normal pressure and exits. cabinet;

[0039] (3) After sterilization, the product is full, with uniform bag shape and high transparency. The pressure inside the bag is tested to be between 0.008-0.013MPa, which improves the bag's ab...

Embodiment 3

[0041] 100ml: glucose injection

[0042] (1) The temperature of the filling liquid is 50°C;

[0043] (2) adopt the vertical loading mode of the present invention;

[0044] (3) Sterilize with a sterilization temperature of 121°C, a sterilization time of 12 minutes, and a sterilization pressure of 0.24MPa; the sterilization starts at 15:23, and when the sterilization temperature reaches 121°C, the pressure reaches 0.24MPa and begins to maintain Sterilize by pressure for 12 minutes, and maintain the pressure at 0.24MPa during the heat preservation stage; after cooling down, the pressure in the cabinet will decrease with the temperature drop, and when the temperature drops to 50°C, the pressure will drop to 0.12MPa and start to release the pressure. At 16:49, the pressure will drop to 10KPa Come out when:

[0045] (3) After sterilization, the product is full, with uniform bag shape and high transparency. The pressure inside the bag is tested to be between 0.011-0.015MPa, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com