A glass steel pipe lining method for circulating water pipes lined with glass steel pipes

A glass steel pipe and circulating water technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems that two pipelines cannot be reconstructed and replaced at the same time, the distance between the two pipelines is small, and the operating pipeline collapses, etc., to achieve The effect of improving external pressure resistance, small backfill workload, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

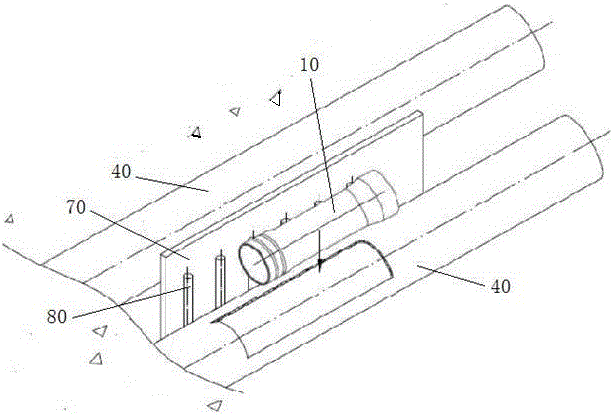

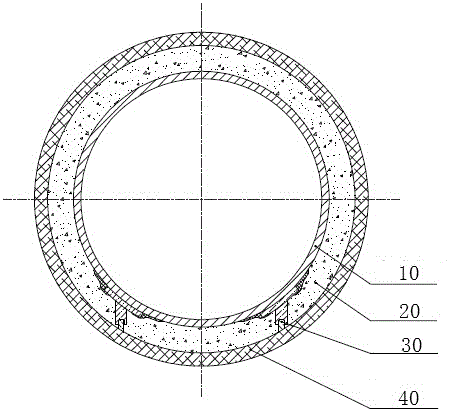

[0025] In a preferred embodiment of the present invention, as figure 1 As shown, the circulating water pipeline lined with glass steel pipes according to the specific embodiment of the present invention includes the original circulating water pipeline 40 and the glass fiber reinforced plastic pipeline 10 lined therein, and cement mortar 20 is used to fill the space between the glass fiber reinforced plastic pipeline 10 and the original circulating water pipeline 40 , the outer wall of the FRP pipe 10 has a track 30 in contact with the inner wall of the original circulating water pipe 40, the origin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com