Novel-structure horizontal machining center machine tool

A machining center and new structure technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome installation, high casting difficulty, large overall area of the base, etc., to reduce the difficulty of installation process, production casting The effect of simplicity, convenience and simplification of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

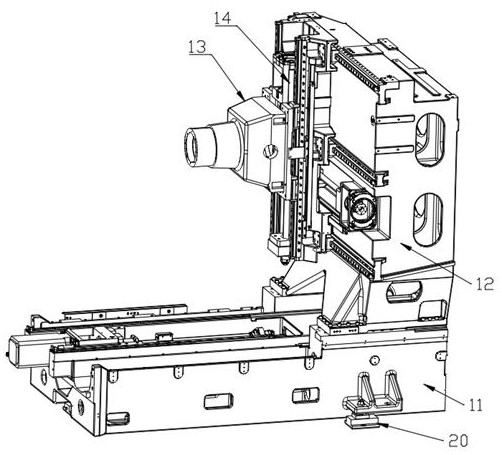

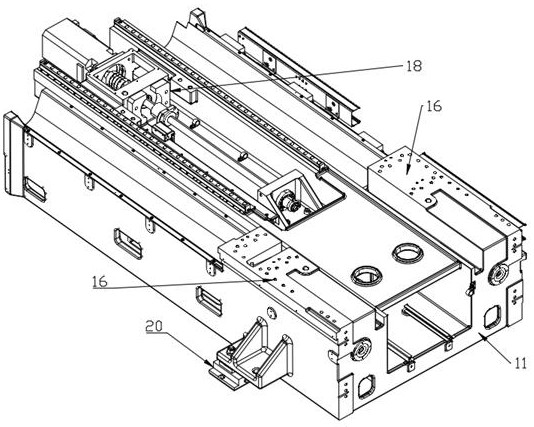

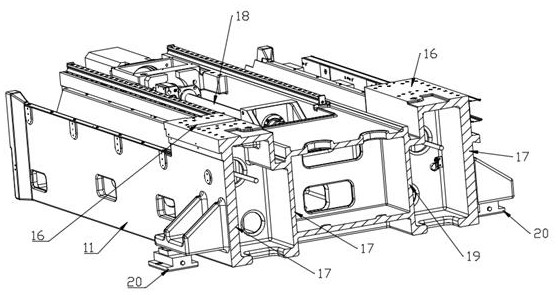

[0031] see Figure 1-8 , in an embodiment of the present invention, a horizontal machining center machine tool with a new structure includes a base 11, a column 12, a headstock 13 and a saddle 14, a line rail 15 is fixedly installed on the upper end of the base 11, and a force-receiving part is arranged on the upper end of the base 11 16. The column 12 is fixedly installed above the force-receiving part 16. A reinforcing rib 17 is provided under the force-receiving part 16. The force-receiving part 16 is supported by the reinforcing rib 17. The left end surface of the column 12 is slidably installed with a saddle 14. The front end of the column 12 is provided with a screw part 18, and the column 12 controls the movement of the saddle 14 through the screw part 18. The front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com