Locking quick-change chuck assembly

a quick-release, chuck technology, applied in the direction of manufacturing tools, mechanical equipment, transportation and packaging, etc., can solve the problems of workers, construction workers and carpenters whoregularly change drill bits in numerous types of construction projects, and may not only be inconvenient to change bits, but also dangerous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

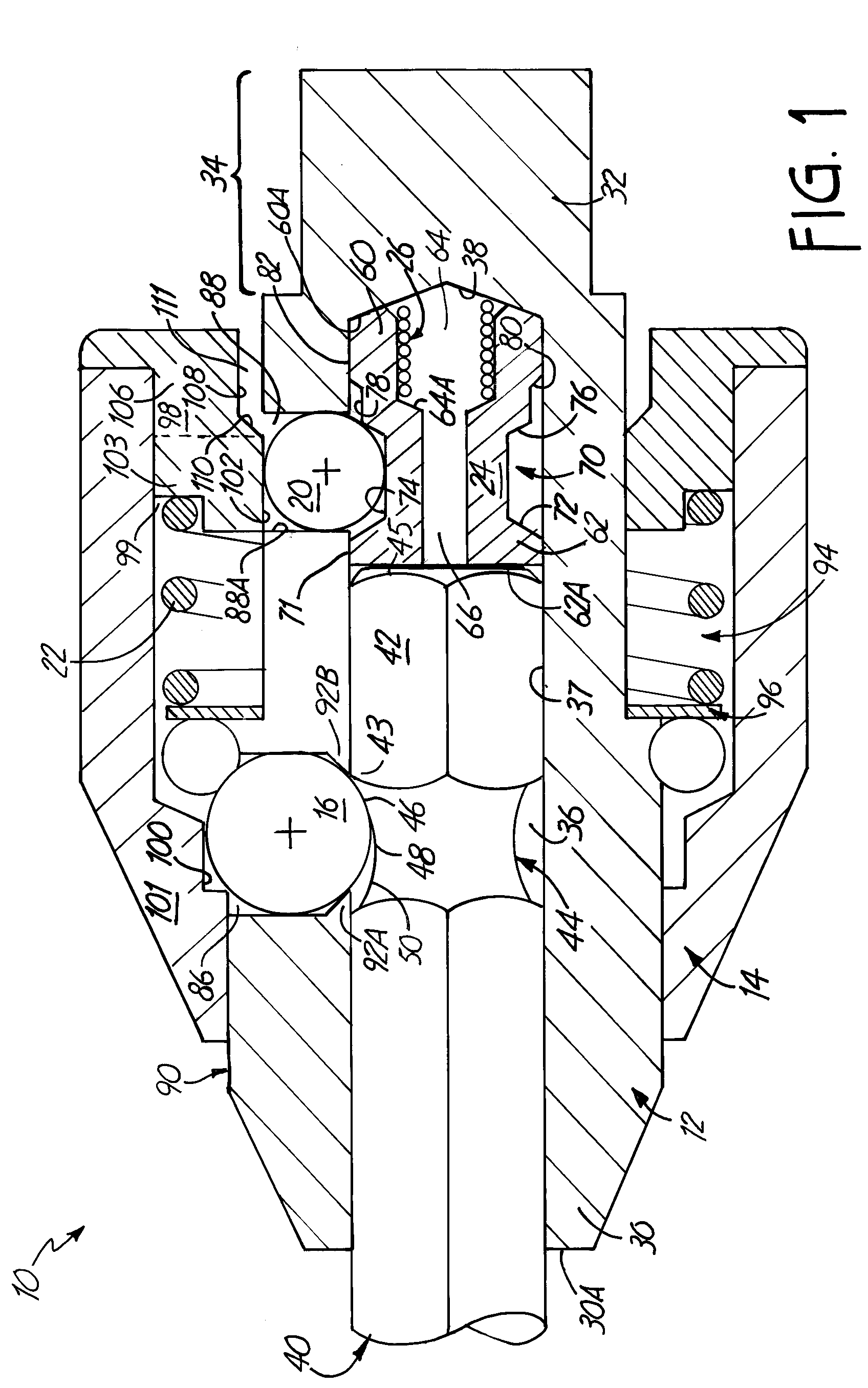

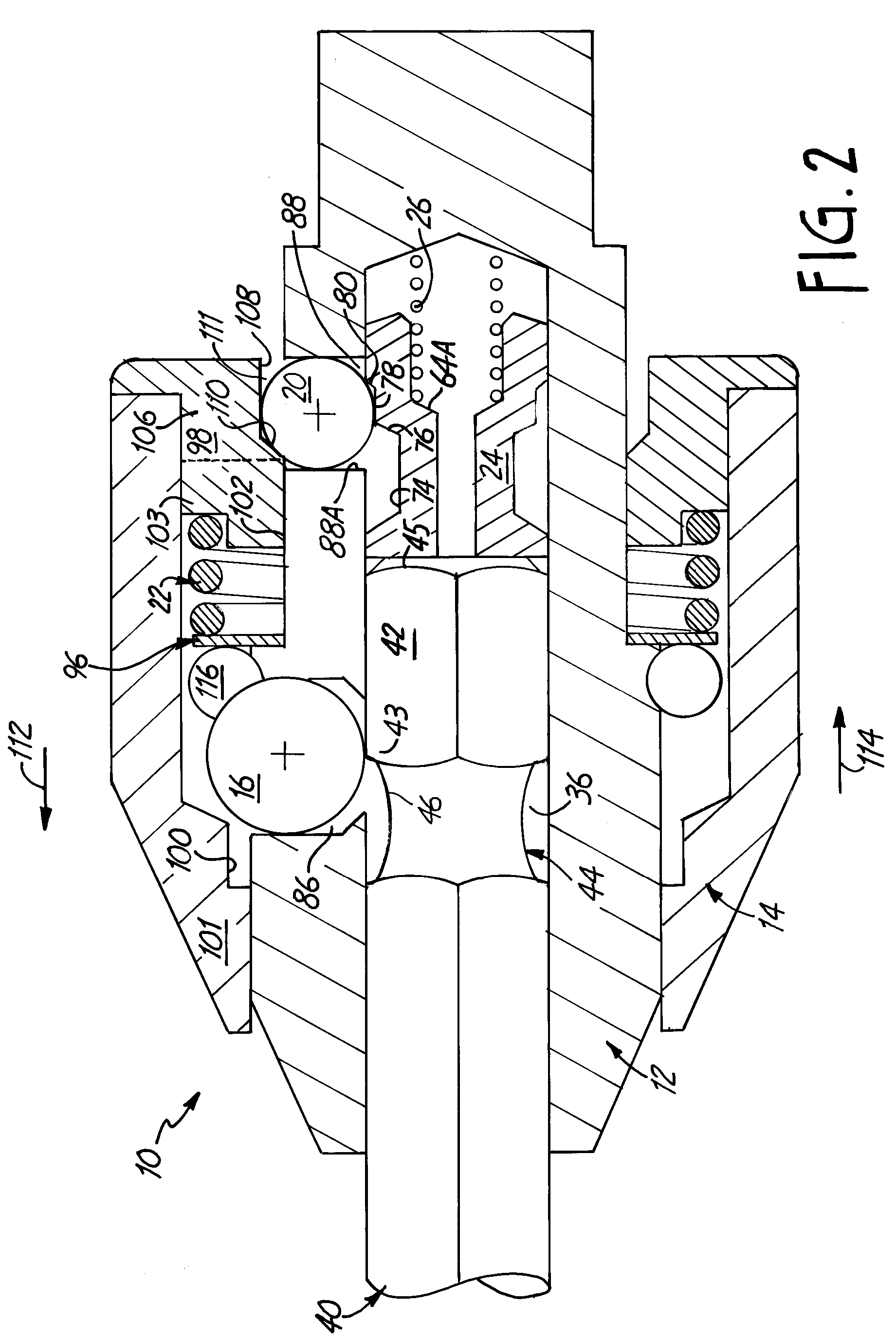

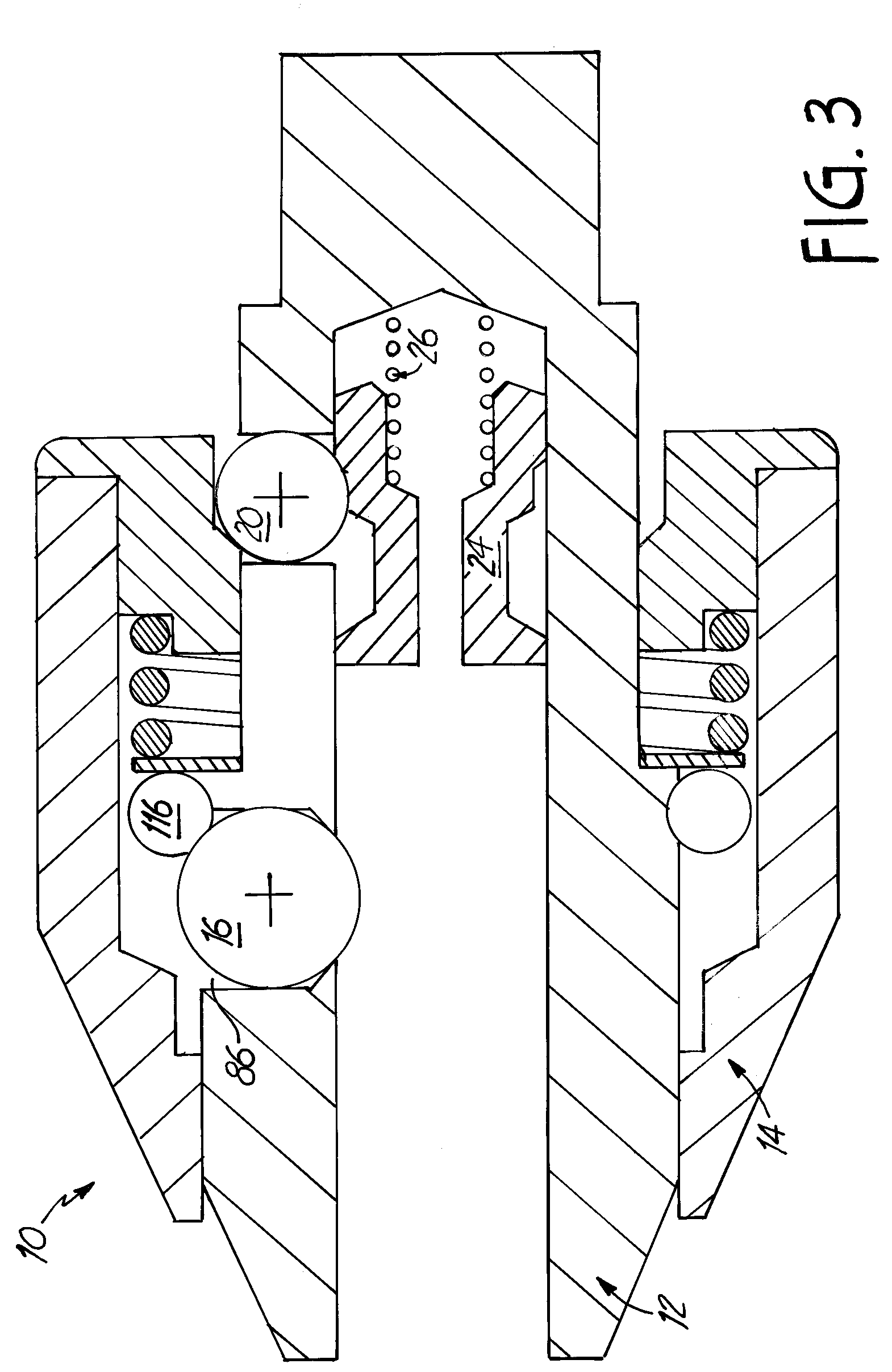

[0034] The present invention is a quick change chuck for a tool bit illustrated generally at 10 in FIG. 1. The chuck 10 includes a chuck hub 12, a sleeve 14, a bit detent ball 16, a shuttle detentball 20, a sleeve spring 22, a shuttle 24 and a shuttle spring 26.

[0035] The chuck hub 12 includes a forward distal end 30 and a driven proximal end 32. The driven end 32 is shaped to form a spindle 34 (typically having a hexagonally shaped cross-section) to provide a connection to the power tool. The forward end 30 terminates in a forwardface 30A. A hexagonal bore 36 extends perpendicularly into the forward face 30A and axiallytowards the driven end 32 of the hub 12. The hexagonal bore 36 is centered in the forward face30A, is substantially aligned along the longitudinal axis of the hub 12 and is shaped to admit astandard quick release tool bit 40. The bore 36 includes an inner wall 37 and terminates in thehub 12 along a terminating face 38. Preferably, the terminating face 38 is generally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com