Efficient permanent magnet submersible mixer with sand prevention and winding prevention functions

A submersible mixer, anti-winding technology, applied in mixers, transportation and packaging, chemical instruments and methods, etc., can solve the problems of easily damaged sealing surface and rubber sheath, affecting service life, destroying mechanical seal sealing surface, etc. Increase the probability of interception, avoid fiber entanglement, and avoid the effect of scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

[0031] It should be noted that, for the convenience of description, the following term "front end" is figure 1 and figure 2 The left end of the figure indicates the installation orientation of the impeller relative to the motor, and the "rear end" is figure 1 and figure 2 The right end of the figure indicates the installation orientation of the motor relative to the impeller.

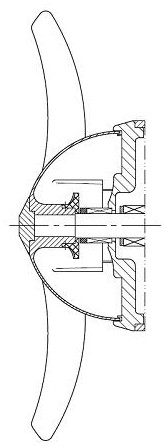

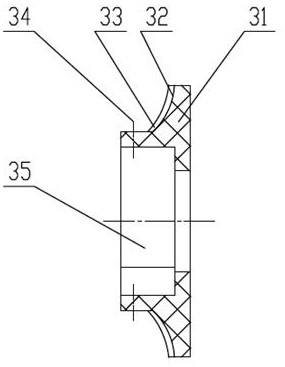

[0032] An embodiment of the present invention provides a high-efficiency permanent magnet submersible mixer with sand prevention and anti-winding functions, such as figure 1 As shown, it includes an impeller 1, a shroud 2, a miniature impeller 3, a mechanical seal seat 4 and a motor 5. The mechanical seal seat 4 is coaxially assembled o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com