Threading robot for building electrical construction

A construction electrical and robotic technology, applied in the field of threading robots, can solve the problems of looseness, entanglement of traction wires and cables, and intricate traction wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

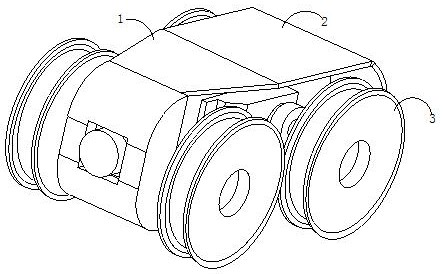

[0030] see figure 1 , the present invention provides a technical solution: a threading robot for building electrical construction, its structure includes a winding device 1, a body 2, and a moving wheel 3, the winding device 1 is connected to the body 2, and the body 2 is connected to the body 2 Both sides of the winding device 1 are provided with moving wheels 3 .

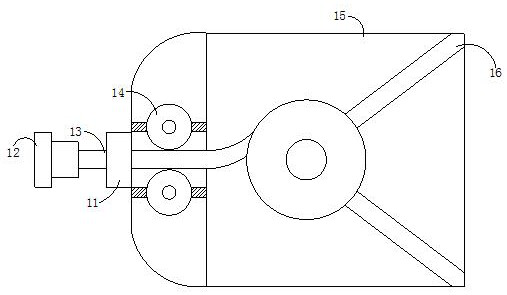

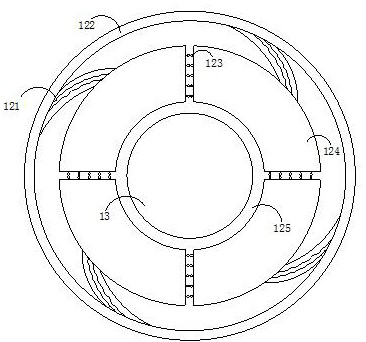

[0031] see figure 2 , the rewinding device 1 includes an interface 11, a docking fastener 12, a pulling wire 13, an auxiliary guide 14, a cavity 15, and a rewinding assembly 16, the interface 11 is fixedly connected to the cavity 15, and the cavity A winding assembly 16 is installed inside the body 15, and the winding assembly 16 is connected to the pulling wire 13, and the pulling wire 13 is connected to the interface 11 through the auxiliary guide 14, and the pulling wire 13 is connected to two auxiliary Between the guides 14, the traction line 13 is inserted and connected to the docking fastener 12, the cav...

Embodiment 2

[0038] see figure 1 , the present invention provides a technical solution: a threading robot for building electrical construction, its structure includes a winding device 1, a body 2, and a moving wheel 3, the winding device 1 is connected to the body 2, and the body 2 is connected to the body 2 Both sides of the winding device 1 are provided with moving wheels 3 .

[0039] see figure 2 , the rewinding device 1 includes an interface 11, a docking fastener 12, a pulling wire 13, an auxiliary guide 14, a cavity 15, and a rewinding assembly 16, the interface 11 is fixedly connected to the cavity 15, and the cavity A winding assembly 16 is installed inside the body 15, and the winding assembly 16 is connected to the pulling wire 13, and the pulling wire 13 is connected to the interface 11 through the auxiliary guide 14, and the pulling wire 13 is connected to two auxiliary Between the guides 14, the traction line 13 is inserted and connected to the docking fastener 12, the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com