A kind of preparation device and preparation method of water-absorbing electrostatic spray non-woven fabric

A technology of electrostatic spraying and preparation equipment, which is applied in the direction of heating equipment, lighting and heating equipment, progressive dryers, etc., and can solve the problem of insufficient drying of non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

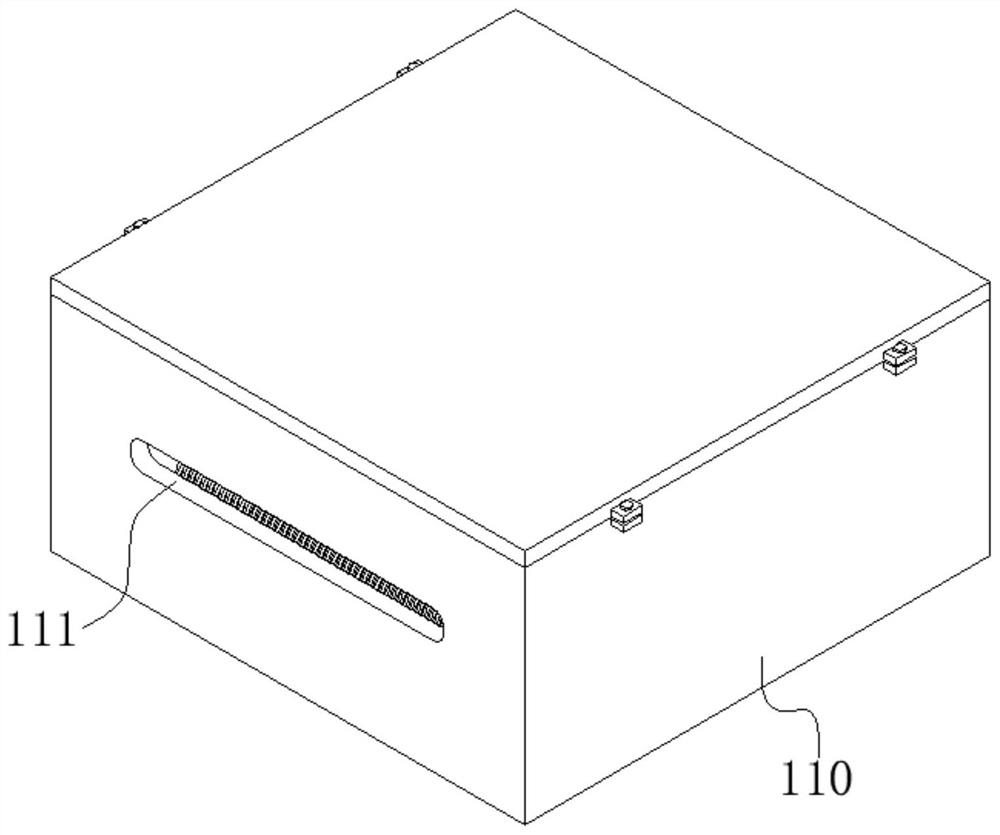

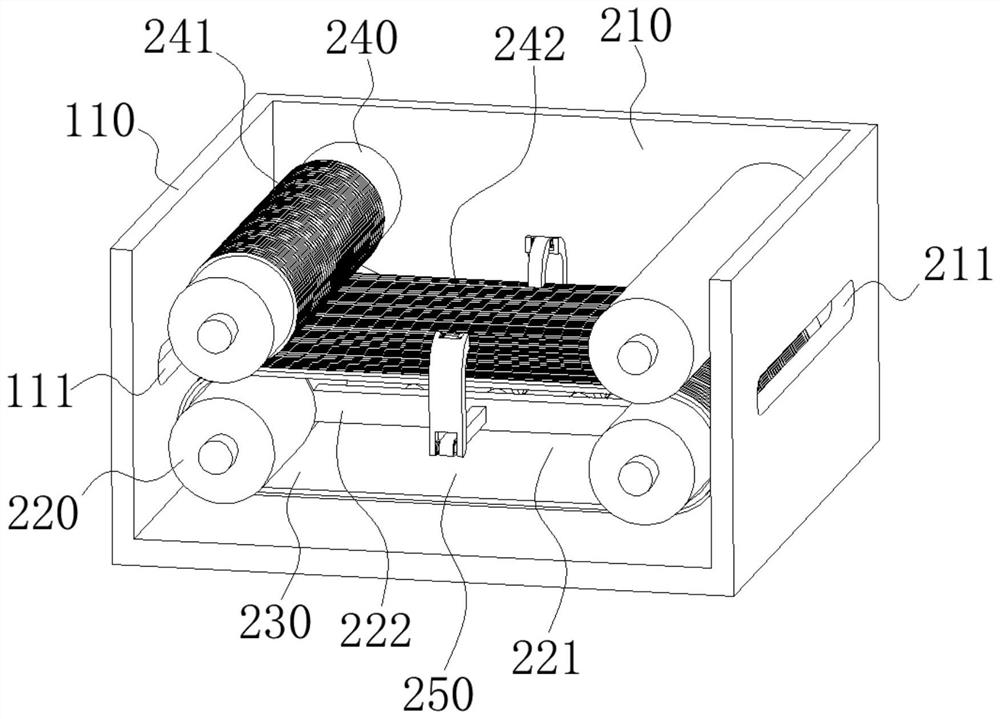

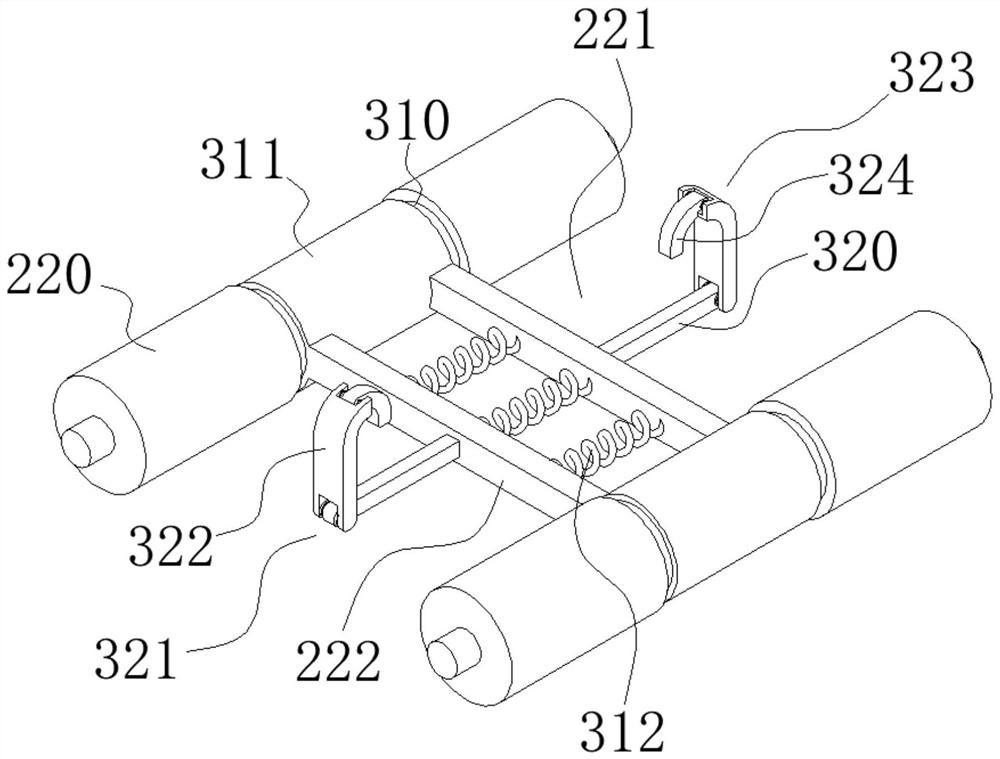

[0037] like Figure 1-4 and Figure 10 As shown, this embodiment provides a preparation device for water-absorbing electrostatic spray non-woven fabric, which includes a housing 110, a processing chamber 210 is arranged in the housing 110, and the opposite side walls of the processing chamber 210 are respectively provided with non-woven fabrics. The feeding port 111 and the discharging port 211 for the cloth to enter and exit; the processing chamber 210 is provided with two rotatable first rollers 220 for conveying non-woven fabrics in parallel, and the outer surfaces of the first rollers 220 are along the first rollers. 220 is provided with a ring-shaped rotating groove 310 in the circumferential direction; a drying mechanism 221 for drying the non-woven fabric is provided between the first rollers 220, and the drying mechanism 221 includes a fixing ring 311 sleeved in the corresponding rotating groove 310, Two first support rods 222 are arranged in parallel between the fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com