Screwdriver

A screwdriver and bit technology, applied in screwdrivers, wrenches, wrenches, etc., can solve the problems of inconvenient operation, obstructing the user's sight, and inability to accurately replace the bit, and achieve the effect of easy installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

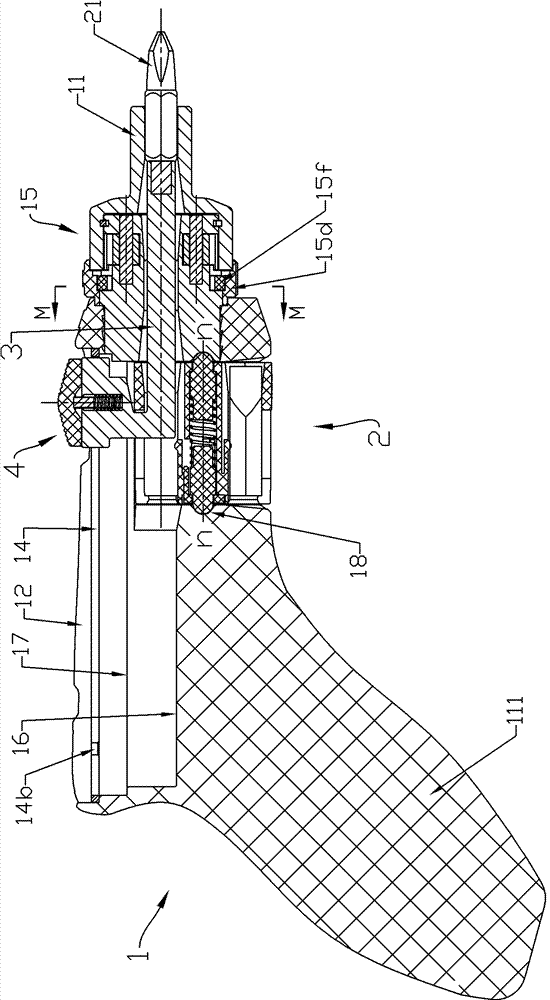

[0084] figure 1 A cross-sectional structure of a preferred embodiment of the screwdriver of the present invention is shown, and the screwdriver includes:

[0085] The handle 1 is provided with a bit sleeve 11 at its front end, and a seam 12 extending forward and backward is provided on the handle 1 at a position behind the bit sleeve 11 and a mounting position 13 visible from the seam 12 is provided, and a slideway is provided on the edge of the seam 12 14. A first positioning part 14a is provided on the front part of the slideway 14;

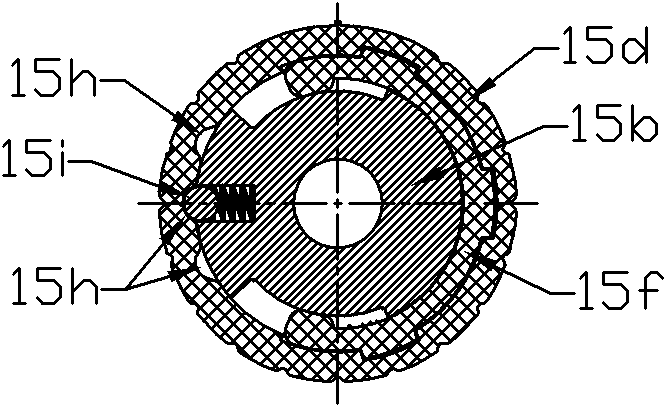

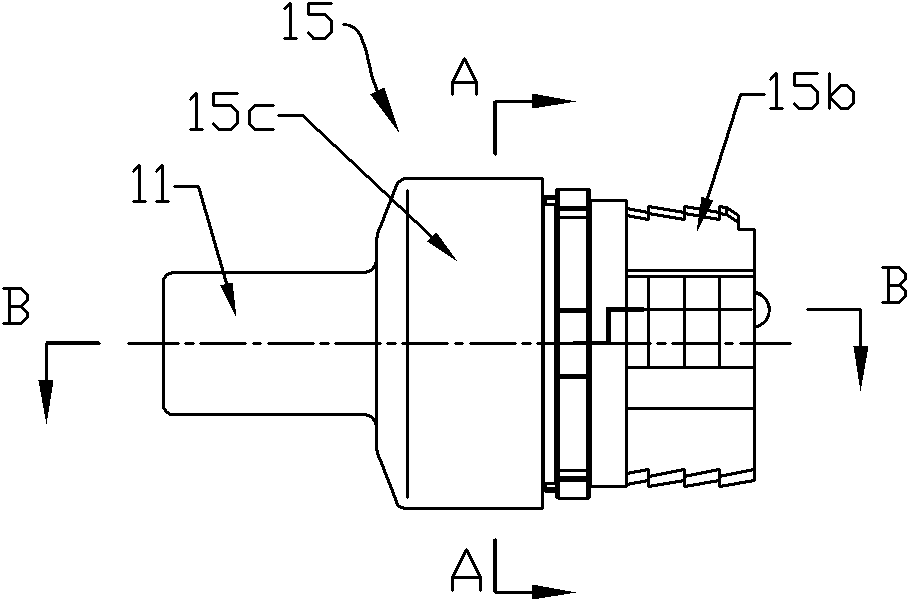

[0086] Wheel bit holder 2 (see Figure 7-15 ), its axis n-n (ie its axis direction, see figure 1 , Figure 12 , Figure 14-15 ) is rotatably installed in the installation position 13 relative to the front-back direction of the handle (the front-back direction of the handle is defined as being consistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com