Concrete structure full life cycle monitoring system and monitoring method

A concrete structure, full life cycle technology, used in measuring devices, instruments, scientific instruments, etc., can solve problems such as easy damage, inability to achieve monitoring effects, etc., to improve stability and durability, reduce signals, and improve compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to more clearly illustrate the embodiments of the present invention and / or the technical solutions in the prior art, the specific implementation manners of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. It should be pointed out that what is described below is only a part of the embodiments of the present invention, rather than all the embodiments. Those of ordinary skill in the art can also obtain other drawings and obtain other implementation manners based on these drawings without making creative efforts.

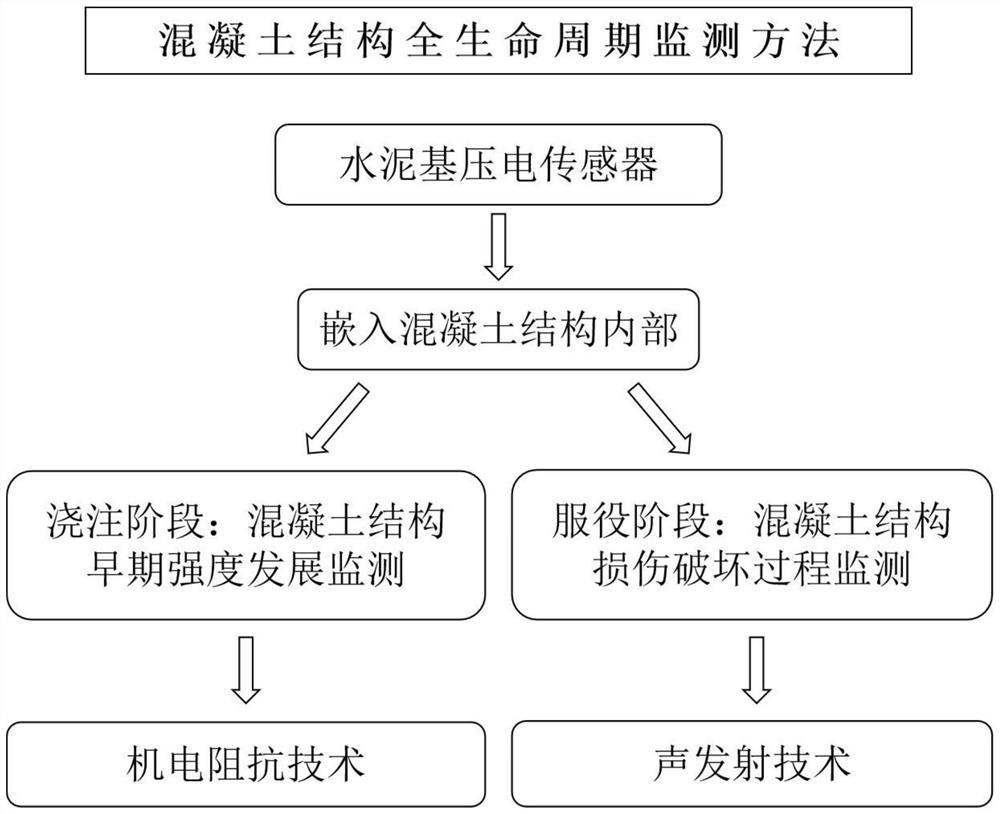

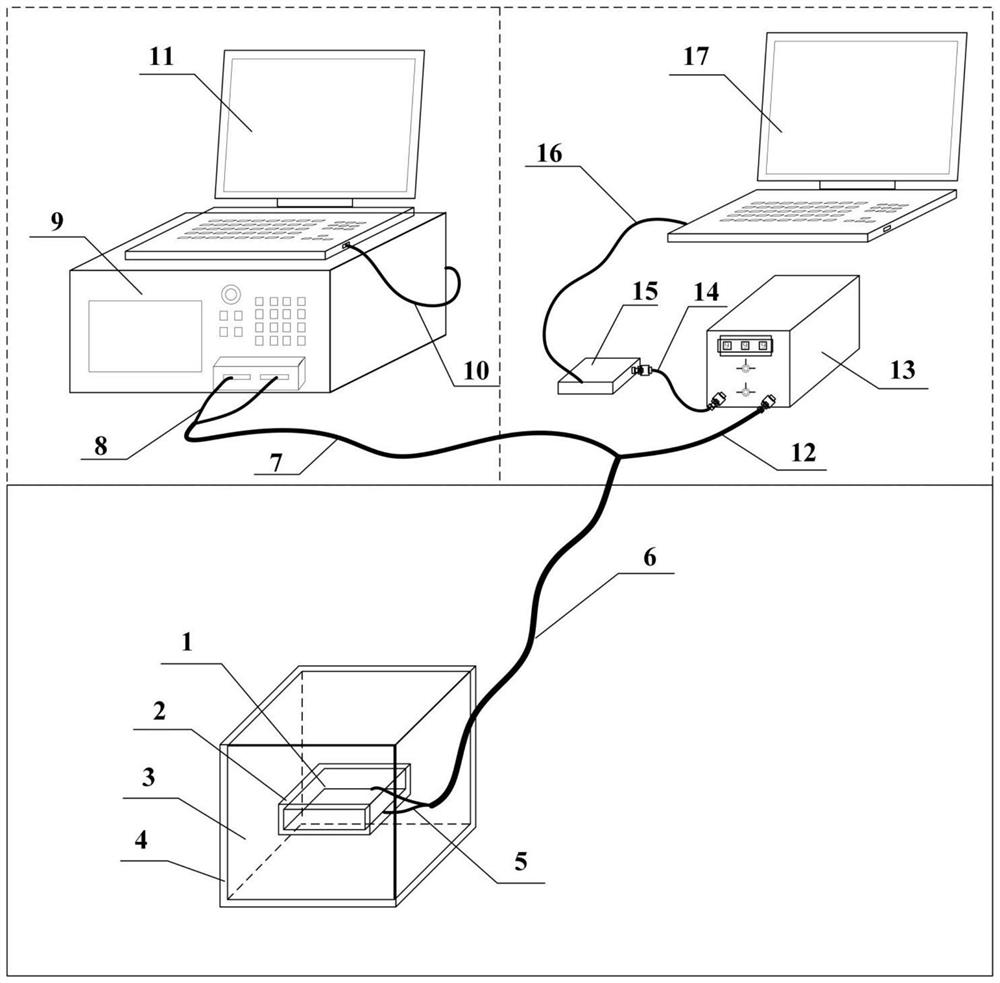

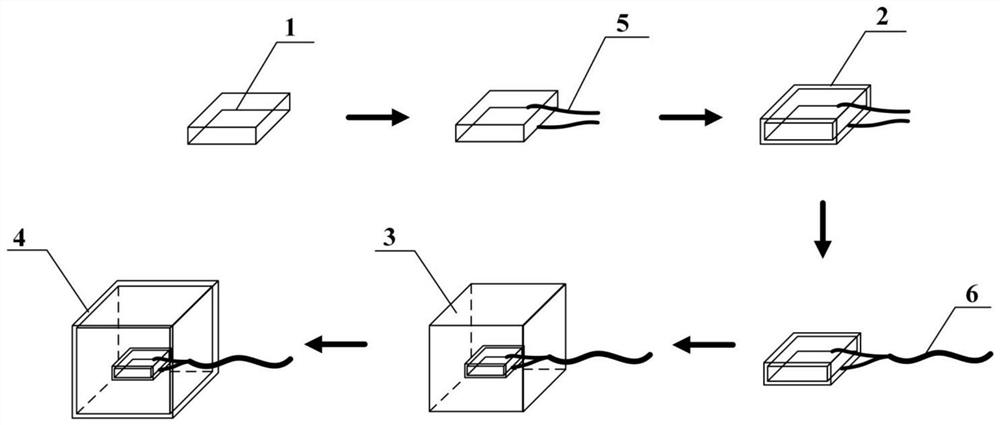

[0047] Such as figure 1 and figure 2 As shown, the present invention provides a concrete structure life cycle monitoring system, including cement-based piezoelectric sensors, impedance testing instruments 9, impedance analysis PC11, charge amplifier 13, data acquisition card 15 and acoustic emission analysis PC17, the cement-based The piezoelectric sensor includes a piezoelectric eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com