Heat-resistant material drilling device

A heat-resistant material and drilling technology, which is used in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of ineffective coolant, difficult to discharge drilling chips, and high temperature of the drill bit, saving manpower, The process of evaporation and heat absorption is fast and the heat dissipation effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

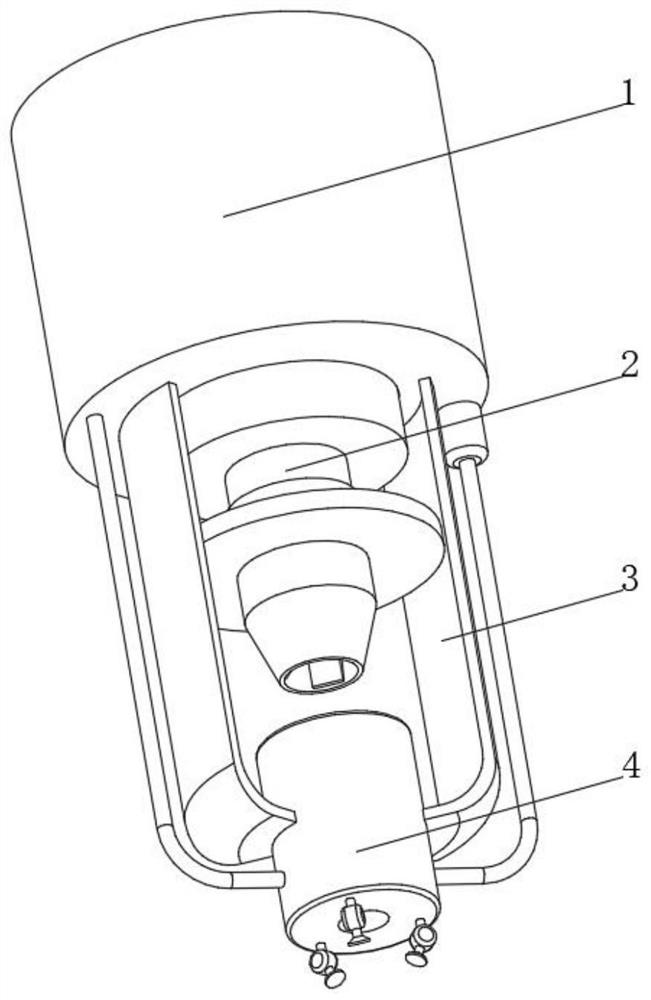

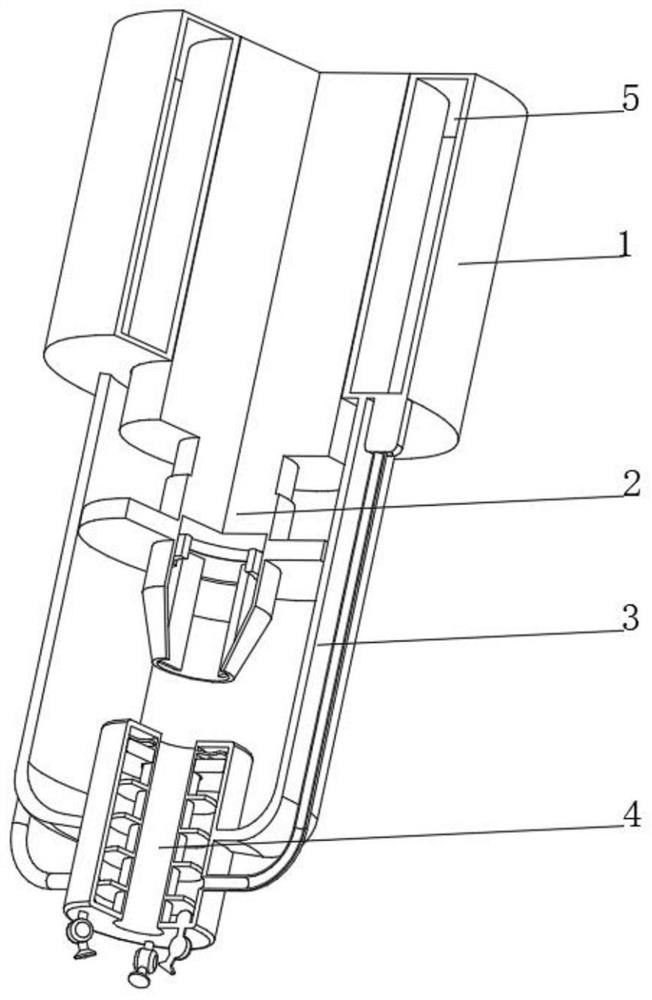

[0034] see Figure 1-4 , the present invention provides a technical solution: a heat-resistant material drilling device, specifically comprising:

[0035] The fixed seat 1, the bottom of the fixed seat 1 is connected with the tool fixed seat 2 through the rotating shaft, the top of the tool fixed seat 2 is fixedly connected with the drive shaft of the external motor through the rotating shaft, and the inside of the fixed seat 1 is provided with a coolant storage tank 5;

[0036] Bracket 3, the bracket 3 is arranged at the bottom of the fixing seat 1 on both sides of the tool fixing seat 2, and the bottom of the bracket 3 is fixedly connected with a cooling device 4;

[0037] Cooling device 4 comprises:

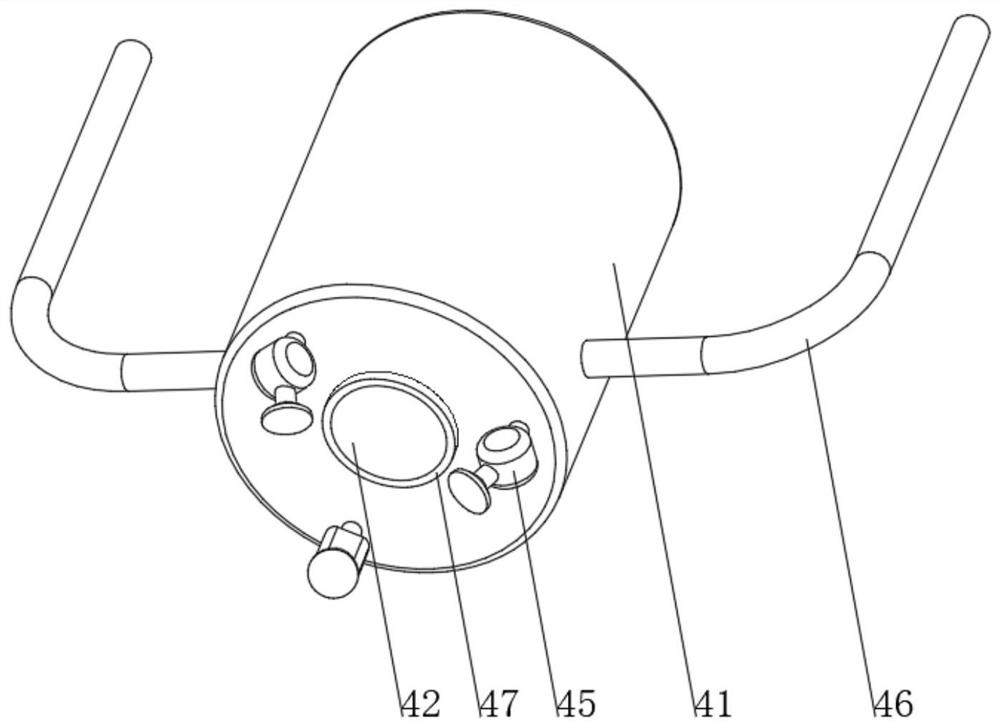

[0038] Cooling cylinder 41, the top and bottom of the cooling cylinder 41 are provided with a through hole 42, the inner wall of the through hole 42 is connected to the limit ring 47 through bearing rotation, and the two sides of the cooling cylinder 41 are connected with a c...

Embodiment 2

[0046] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the nozzle device 45 includes a liquid outlet pipe 451, one end of the liquid outlet pipe 451 is connected with a fixed disk 452, one side of the fixed disk 452 is connected with a rotating disk 453, and the fixed disk 452 The inner wall and the outer wall of the rotating disk 453 are rotationally connected by sealed bearings. One side of the rotating disk 453 is connected with a nozzle 454, and the end of the nozzle 454 far away from the rotating disk 453 is connected with an atomizing nozzle 455. The nozzle device 45 is provided with multiple groups and uniform Distributed at the bottom of the cooling cylinder 41 , the top of the outlet pipe 451 communicates with the interior of the cooling cylinder 41 , and a damping pad is provided between the fixed disk 452 and the rotating disk 453 .

[0047] A nozzle device 45 is provided. When the pressure inside the cooling cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com