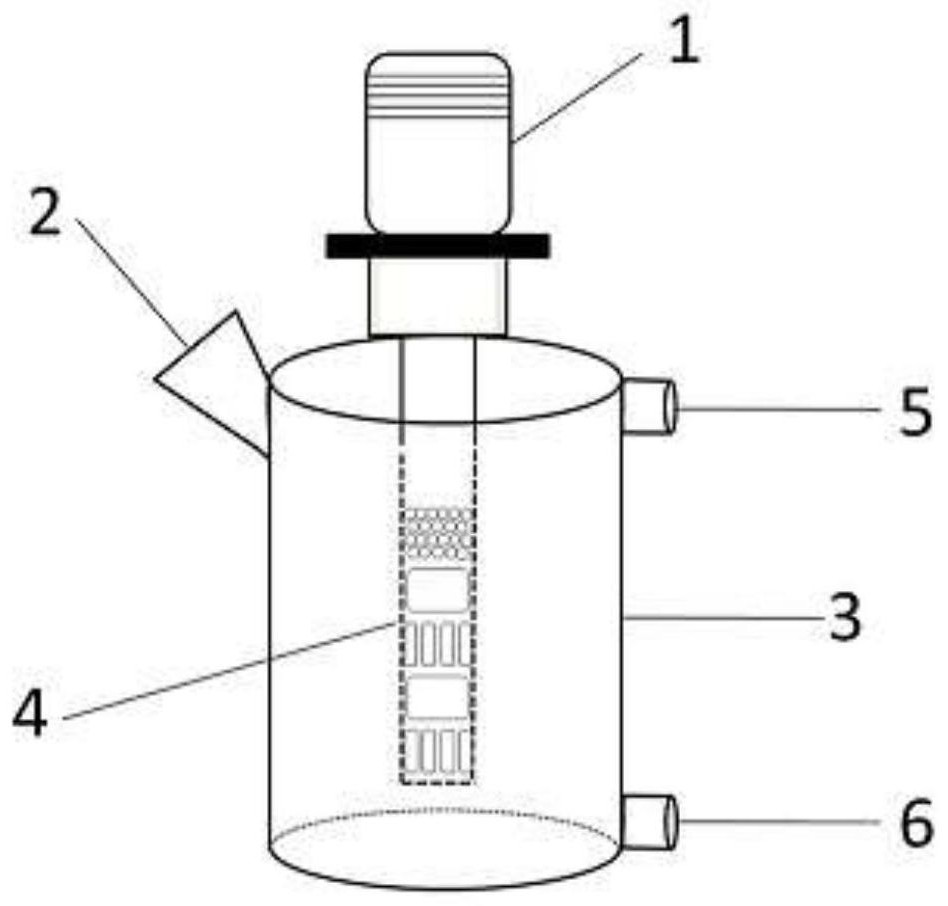

Oil sludge homogenization reaction device and homogenization method

A reaction device and homogenization technology, applied in chemical instruments and methods, sludge treatment, transportation and packaging, etc., can solve the problems of high energy consumption and poor homogenization effect, and achieve low energy consumption and poor improvement effect , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

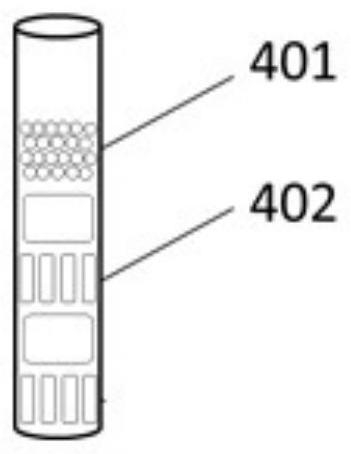

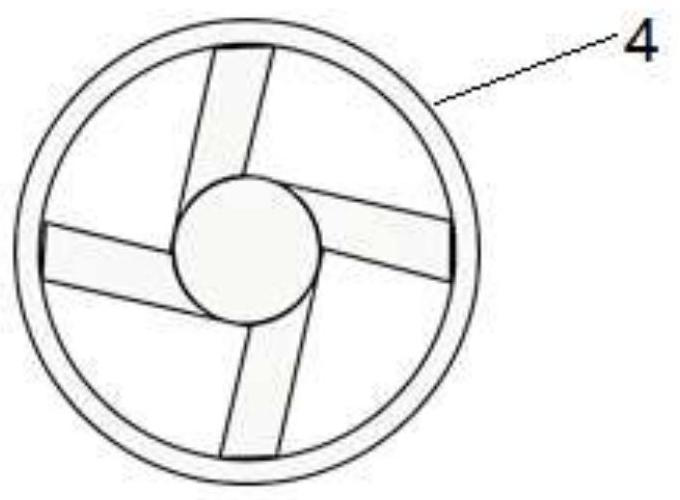

Method used

Image

Examples

Embodiment 1

[0028] A homogenization method based on a sludge homogenization reaction device, comprising the following steps:

[0029] (1) Add oil sludge and water to the feed port of the oil sludge homogenization reaction device, and the weight ratio of oil sludge and water is 1:2.

[0030] (2) Turn on the motor 1, control the rotor speed to 6000r / min, and the running time to 3min.

[0031] (3) After the treated oil sludge slurry enters the centrifuge through the collection port for further dehydration and oil removal, the remaining solids are collected to detect the oil content.

[0032] Using the technology of the present invention, homogenization treatment is carried out for Daqing oil sludge (oil content 15%), and the oil content of oil sludge after treatment is 1.8%, which reaches the current general industry standard "Pollution Control Standard for Comprehensive Utilization of Oilfield Oily Sludge" (DB23 / T1413-2010) is a 2% requirement.

Embodiment 2

[0034] A homogenization method based on a sludge homogenization reaction device, comprising the following steps:

[0035] (1) Add oil sludge and water to the feed port of the oil sludge homogenization reaction device, and the weight ratio of oil sludge and water is 1:2.

[0036] (2) Turn on the motor, control the rotor speed to 6000r / min, and run for 3 minutes.

[0037] (3) After the treatment, the sludge slurry enters the centrifuge through the collection port for further dehydration and oil removal.

[0038] (4) Add the oil sludge collected after dehydration and degreasing, water and inorganic mineral restoration agent from the feed port of the sludge homogenization reaction device, wherein the weight ratio of the oil sludge collected after dehydration and degreasing to water is 1:1, The amount of restoration agent added is 20% of the weight of the sludge.

[0039] (5) Turn on the driving motor, control the rotor speed to 3000r / min, and the running time to 2min.

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com