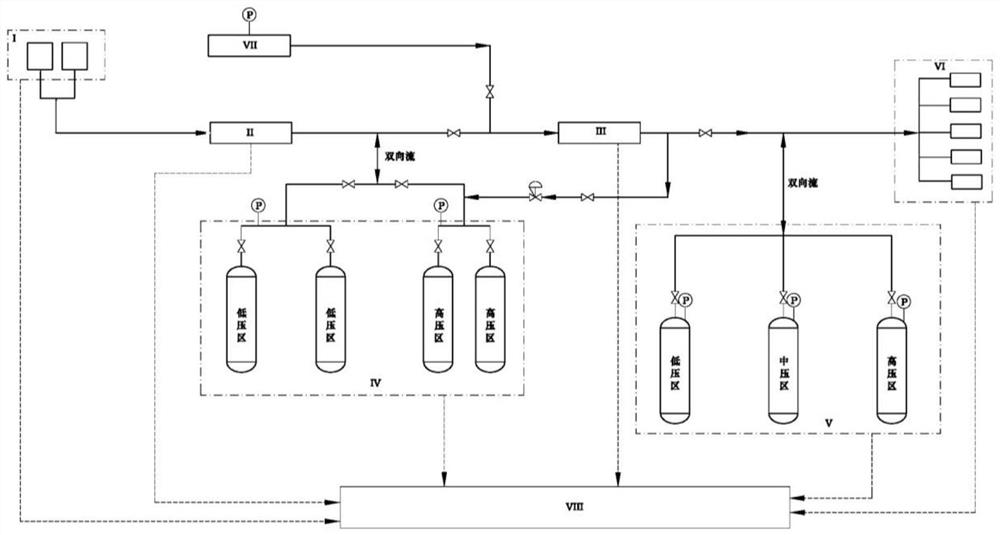

Equipment type selection method of hydrogen production and hydrogenation station system

A technology for equipment type selection and hydrogen production equipment, applied to the method of container discharge, equipment discharged from pressure vessels, mechanical equipment, etc., can solve problems such as complex and difficult operation management, increased equipment investment, and increased maintenance costs. Achieve the effect of reducing the frequency of frequent start and stop, improving the utilization rate of hydrogen, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] In a certain area, it is planned to build a hydrogen refueling station with in-station hydrogen production. The service objects of the hydrogen refueling station are surrounding buses, small cars, muck trucks and other heavy trucks, cranes in surrounding industrial sites, passenger buses, etc., including 20 small cars 30 vehicles, buses and passenger buses, 10 heavy trucks, 20 cranes, and no other vehicles use hydrogen.

[0130] Among them, according to the research on the hydrogenation situation in this area, the concentrated hydrogenation time is from 9:00 to 21:00, in which the hydrogenation volume reaches 70kg / h for 5 consecutive hours, and there is almost no hydrogenation at night. The hydrogen refueling station is very sensitive to the shutdown of the hydrogen production equipment and needs to maintain continuous operation; the second sensitive factor is the secondary compressor, which reduces the number of startups and reduces maintenance costs.

[0131] Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com