Hydraulic oil cylinder barrel structure capable of preventing axial rotation

A technology of hydraulic oil cylinder and axial rotation, applied in the field of hydraulic cylinder, can solve the problem that the axial rotation of the piston rod cannot be prevented, and achieve the effect of improving the clamping and limiting effect, preventing offset and improving the limiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

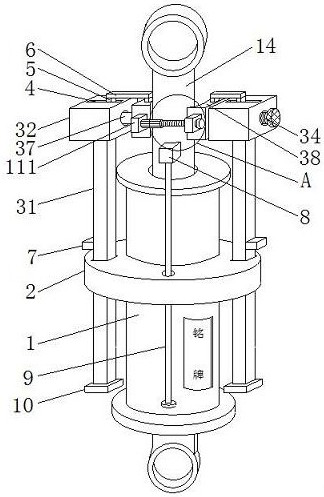

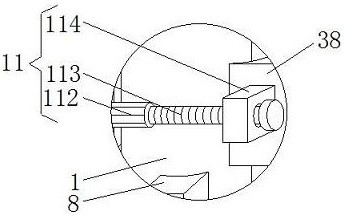

[0027] refer to Figures 1 to 6 , a hydraulic cylinder structure for preventing axial rotation, comprising a cylinder body 1, a fixed plate 2 is welded on the surface of the cylinder body 1, a piston rod 14 is movably connected to the center of the top of the cylinder body 1, and the piston rod 14 The center of the top is welded with a first fixed block, and the center of the front of the first fixed block is provided with a first connecting hole, and both sides of the piston rod 14 are provided with a clamping mechanism 3. Limiting mechanisms 11 are arranged on both sides, a second fixing block is welded at the center of the bottom of the cylinder body 1, and a second connection hole is opened at the center of the front bottom of the second fixing block.

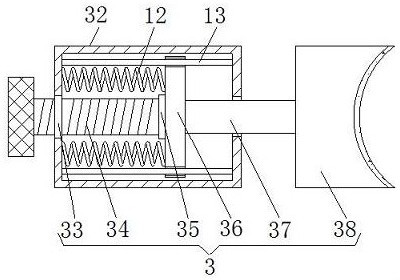

[0028] Clamping mechanism 3 comprises movable post 31, fixed box 32, first threaded sleeve 33, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com