Natural ester insulating liquid

A technology of insulating liquid and natural ester, applied in the petroleum industry, lubricating composition, etc., can solve the problems of low flash point and low freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

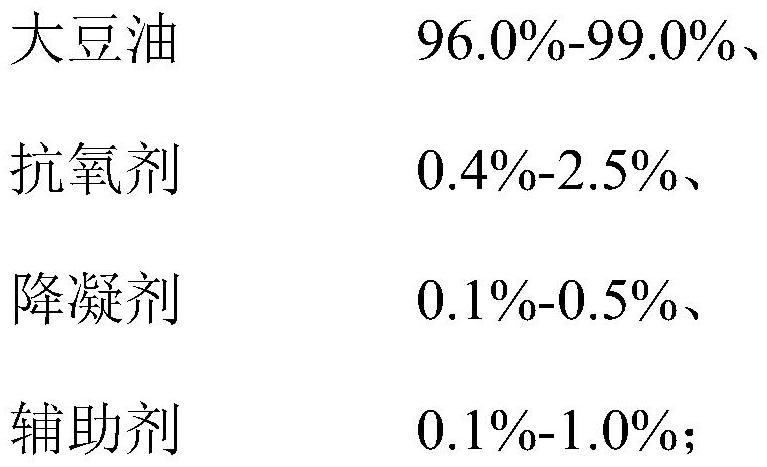

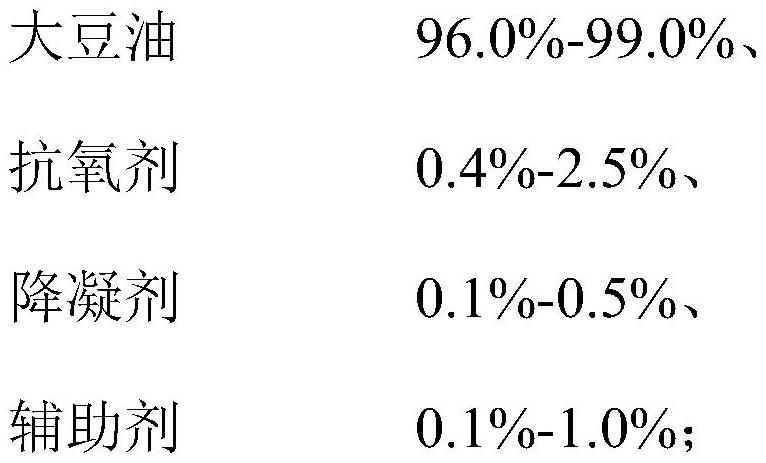

[0087] This example provides a natural ester insulating liquid, the specific formula of which is shown in Table 1. The natural ester insulating liquid is prepared by the following steps:

[0088] In terms of mass percentage, heat 98.1% soybean oil to 50-60°C, add 0.1% tocopherol, 0.3% sterol, 0.6% antioxidant T501, 0.2% citric acid, 0.2% pour point depressant Mix and stir with 0.5% auxiliary agent for 20-30min, cool to room temperature, wherein, the tocopherol is composed of 10% α-tocopherol, 3% β-tocopherol, 72% γ-tocopherol and 25% δ-tocopherol, The sterols consisted of 5% campesterol, 25% stigmasterol and 70% β-sitosterol to prepare natural ester insulating oil.

[0089] Table 1

[0090]

Embodiment 2

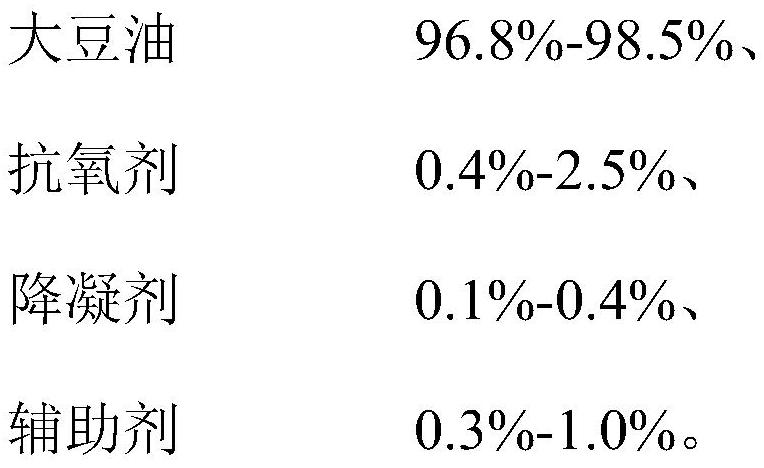

[0092] This embodiment provides a natural ester insulating liquid, the specific formula of which is as described in Table 2. The natural ester insulating liquid is prepared by the following steps:

[0093]In mass percentage, heat 97.9% soybean oil to 50-60°C, add 0.2% tocopherol, 0.4% sterol, 0.5% antioxidant T501, 0.1% citric acid, 0.1% pour point depressant Mix and stir with 0.8% auxiliary agent for 20-30min, cool to room temperature, wherein, the tocopherol is composed of 13% α-tocopherol, 5% β-tocopherol, 64% γ-tocopherol and 18% δ-tocopherol, The sterols consisted of 4% campesterol, 28% stigmasterol and 68% β-sitosterol to prepare a natural ester insulating oil.

[0094] Table 2

[0095]

Embodiment 3

[0097] This embodiment provides a natural ester insulating liquid, the specific formula of which is shown in Table 2. The natural ester insulating liquid is prepared by the following steps:

[0098] In terms of mass percentage, heat 98.3% soybean oil to 50-60°C, add 0.15% tocopherol, 0.35% sterol, 0.3% antioxidant T501, 0.2% citric acid, and 0.3% pour point depressant Mix and stir with 0.4% auxiliary agent for 20-30min, cool to room temperature, wherein, the tocopherol is composed of 8% α-tocopherol, 4% β-tocopherol, 75% γ-tocopherol and 13% δ-tocopherol, The sterols consisted of 2% campesterol, 25% stigmasterol and 73% β-sitosterol to prepare natural ester insulating oil.

[0099] table 3

[0100]

[0101]

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com