Concrete mixture using magnesium oxychloride cement to solidify coal gasification slag and preparation method thereof

A technology of magnesium oxychloride cement and coal gasification slag, which is applied in the field of building materials, can solve the problems of low strength of concrete building materials, high carbon content of coal gasification slag, and low comprehensive utilization rate, so as to reduce the overall moisture content and improve the solidification strength , the effect of low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

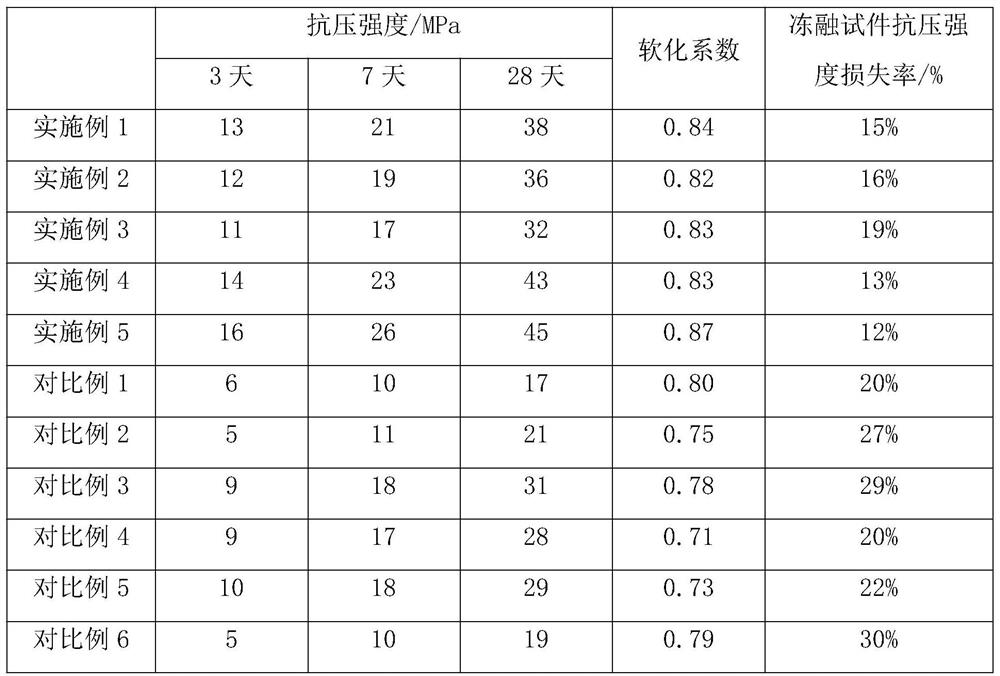

Embodiment 1

[0049] The preparation method of the concrete mixture that utilizes magnesium oxychloride cement to solidify coal gasification slag, comprises the following steps:

[0050] Step 1, take by weight the total amount of 60 parts of coal gasification slag respectively, wherein the coarse slag and fine slag mass ratio is 7:3, the coarse slag and the fine slag are mixed and stirred for 5min, and 11 parts of halogen chips are weighed, Add to the mixed coal gasification slag, stir for 5min, and let stand for 30min to obtain Mixture I;

[0051] Step 2, weigh 0.1 part of trisodium phosphate, 0.1 part of citric acid and 0.3 part of styrene-butadiene rubber emulsion by weight, add them to the mixture I of step 1, and stir for 10min to obtain the mixture II;

[0052] Step 3, weigh 15 parts of fly ash by weight, add it to the mixture II in step 2, and stir for 10 min to obtain the mixture III;

[0053] Step 4: Weigh 12.5 parts of light-burned magnesium powder by weight, add it to the mixtur...

Embodiment 2

[0055] The preparation method of the concrete mixture that utilizes magnesium oxychloride cement to solidify coal gasification slag, comprises the following steps:

[0056] Step 1, take by weight the total amount of 70 parts of coal gasification slag respectively, wherein the coarse slag and fine slag mass ratio is 7:3, the coarse slag and the fine slag are mixed and stirred for 5min, and 8 parts of halogen chips are weighed, Add to the mixed coal gasification slag, stir for 10min, and let stand for 30min to obtain Mixture I;

[0057] Step 2, weigh 0.1 part of trisodium phosphate, 0.05 part of phosphoric acid, 0.15 part of oxalic acid and 0.3 part of polytetrafluoro emulsion by weight, add it to the mixture I of step 1, and stir for 10 minutes to obtain the mixture II;

[0058] Step 3, weigh 11.4 parts of fly ash by weight, add it to the mixture II in step 2, and stir for 10 min to obtain mixture III;

[0059] Step 4: Weigh 10 parts of light-burned magnesium powder by weight,...

Embodiment 3

[0061] The preparation method of the concrete mixture that utilizes magnesium oxychloride cement to solidify coal gasification slag, comprises the following steps:

[0062] Step 1, take by weight the total amount of 85 parts of coal gasification slag respectively, wherein the coarse slag and fine slag mass ratio is 8:2, the coarse slag and the fine slag are mixed and stirred for 10min, and 5 parts of halogen chips are weighed, Add to the mixed coal gasification slag, stir for 10min, and let stand for 30min to obtain Mixture I;

[0063] Step 2, weigh 0.1 part of sodium metaphosphate, 0.1 part of citric acid and 0.5 part of styrene-butadiene rubber emulsion by weight, add them to the mixture I of step 1, and stir for 10min to obtain the mixture II;

[0064] Step 3, weigh 2 parts of fly ash by weight, add it to the mixture II of step 2, and stir for 5 minutes to obtain the mixture III;

[0065] Step 4: Weigh 7.3 parts of light-burned magnesium powder by weight, add it into the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com