Full-speed fin stabilizer based on complete Weis-Fogh structure and control method thereof

A weis-fogh and fin stabilizer technology, applied in the field of full speed fin stabilizer and its control, can solve the problems of complex structure, inconvenient rotation, etc., and achieve the effect of large lift, compatibility and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

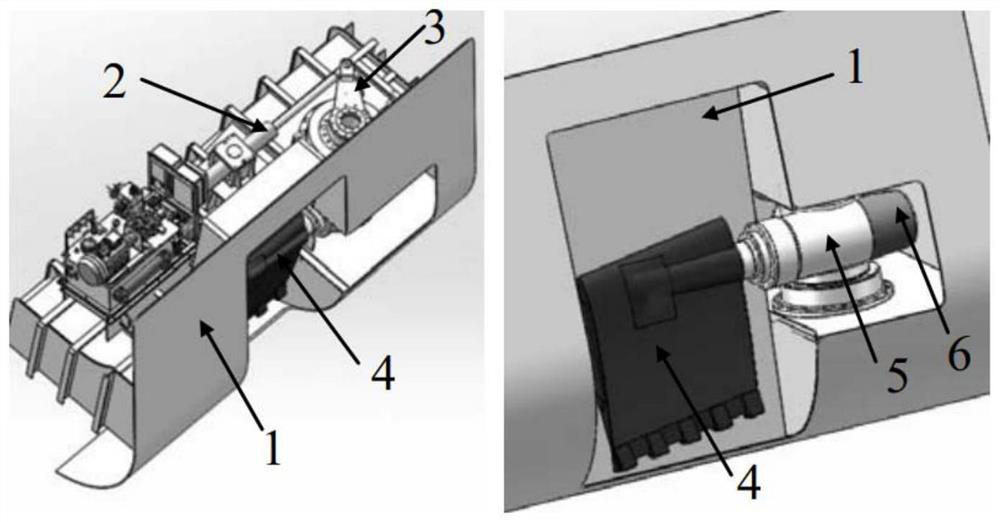

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

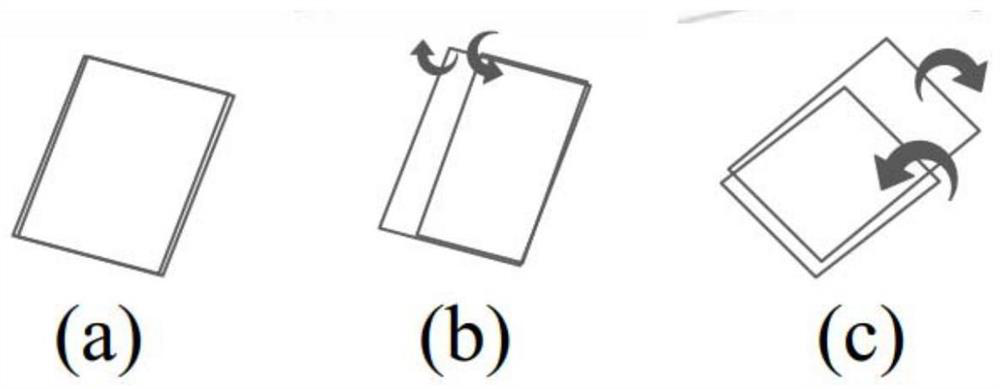

[0033] Step 1: According to the roll information of the ship obtained by the attitude sensor, at zero or low speed, at the beginning of a cycle, the tip chord of the fin blade is vertically upward, and the fin blade and the upper side of the hull are attached together, and the included angle is 0 degree, such as Figure 4 In (a) shown.

[0034] Step 2: The piston rod of the opening and closing oil cylinder is retracted for a section, so that the bow chord of the fin blade is rapidly opened 30 degrees relative to the upper side of the hull, and this process does not exceed 1 / 10 of the rolling period, such as Figure 4 In (b) shown.

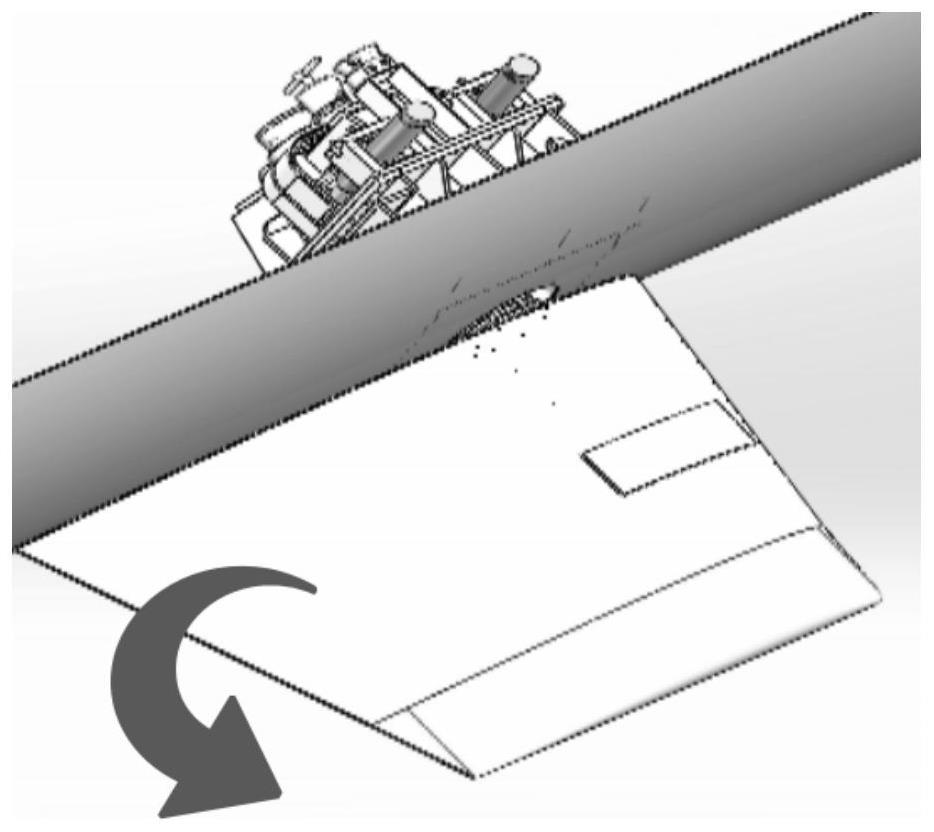

[0035] Step 3: The hydraulic motor drives the fins to start to accelerate and flap downwards, and at the same time the piston rod of the opening and closing cylinder stretches out. When the fins move to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com