Furnace discharge robot steel chisel straightening machine

A straightening machine and robot technology, applied in the field of steel processing, can solve the problem of manual straightening and other problems, and achieve the effect of obvious straightening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

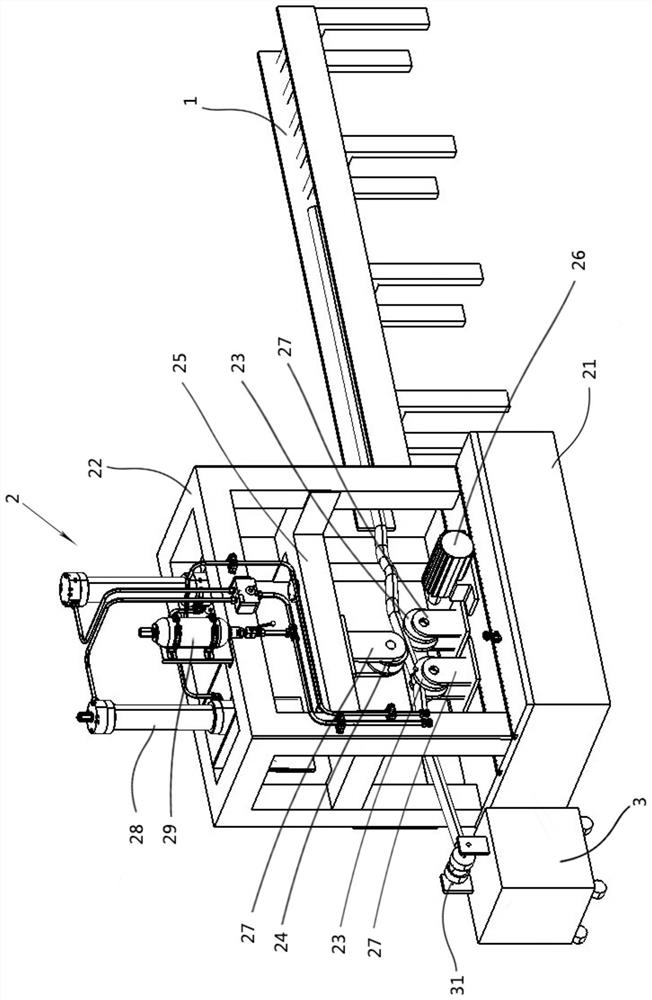

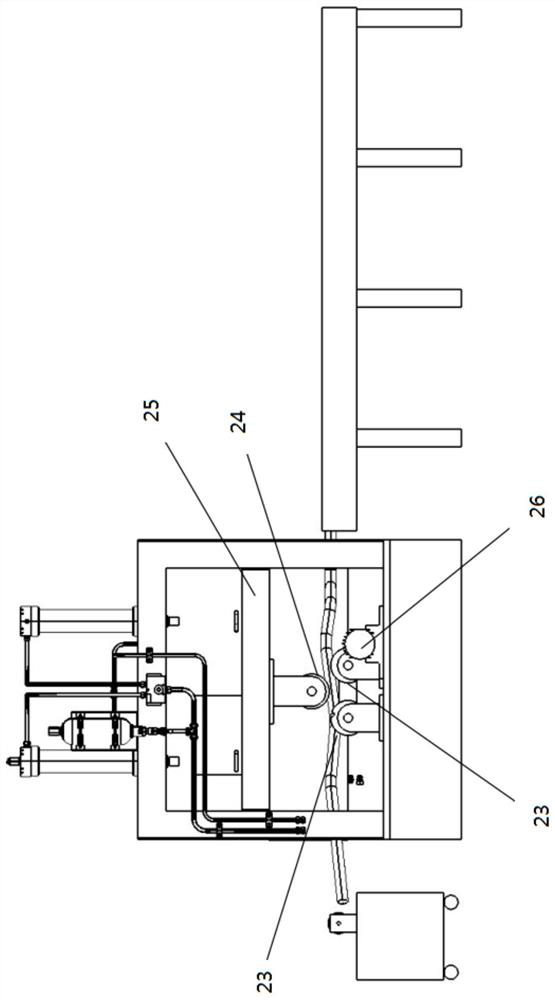

[0027] See Figure 1 - Figure 2 The embodiment of the present invention provides the following embodiments:

[0028] Brazing the machine steel brazing straight machine, including the feeding table 1, the straightening device 2, and the conductive station 3, the conductive station 3, the conductive station 3, the conductive station 3, processed by the straightening device 2) The material is exported. In the above configuration, the straightening device 2 includes a base 21, a frame 22, aater roller 23, a lower pressure roller 24, a lifting bracket 25, and a motor 26; the active roller 23 is fixed to the base 21 through the roller bracket 27, The feed direction is sequentially provided in two, wherein the two active rollers 23 are respectively coupled to the two roller brackets 27, and the two roller brackets 27 are detachably fixed above the base 21, and the two active roller 23 are fed. The direction is set to a straight line setting, and the height is consistent, and both the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com