An automatic adjustment device for processing parameters of a spiral air duct and a spiral air duct machine

A technology for automatic adjustment of processing parameters, which is applied in the field of spiral air duct machines and automatic adjustment devices for processing parameters of spiral air ducts, can solve the problems of reducing production efficiency, generating waste products, and taking a long time, so as to improve production efficiency and improve Efficiency and accuracy, the effect of reduced time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

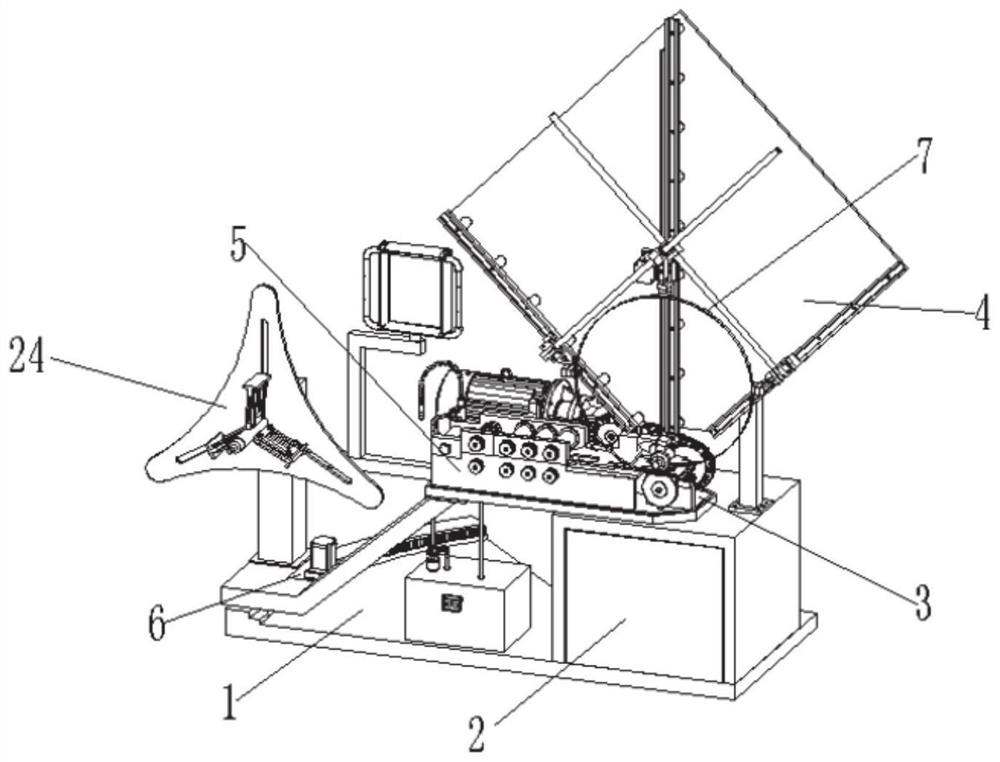

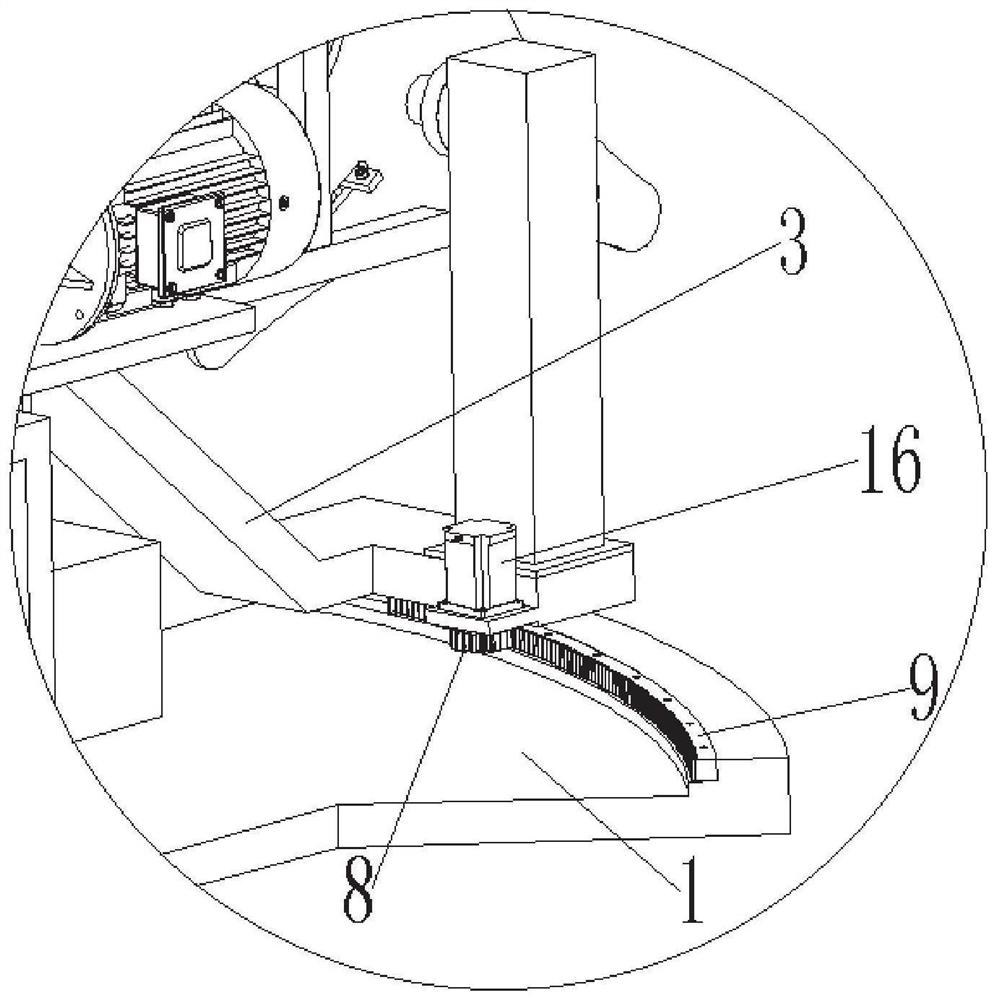

[0032] In a typical embodiment of the present invention, as Figure 1-Figure 4 As shown, an automatic adjustment device for processing parameters of a spiral air duct is proposed, including a base 1, and a diameter adjustment mechanism 4 and a helix angle adjustment mechanism 6 are arranged on the base 1, and the two are respectively used to adjust the diameter and the helix angle of the spiral air duct. .

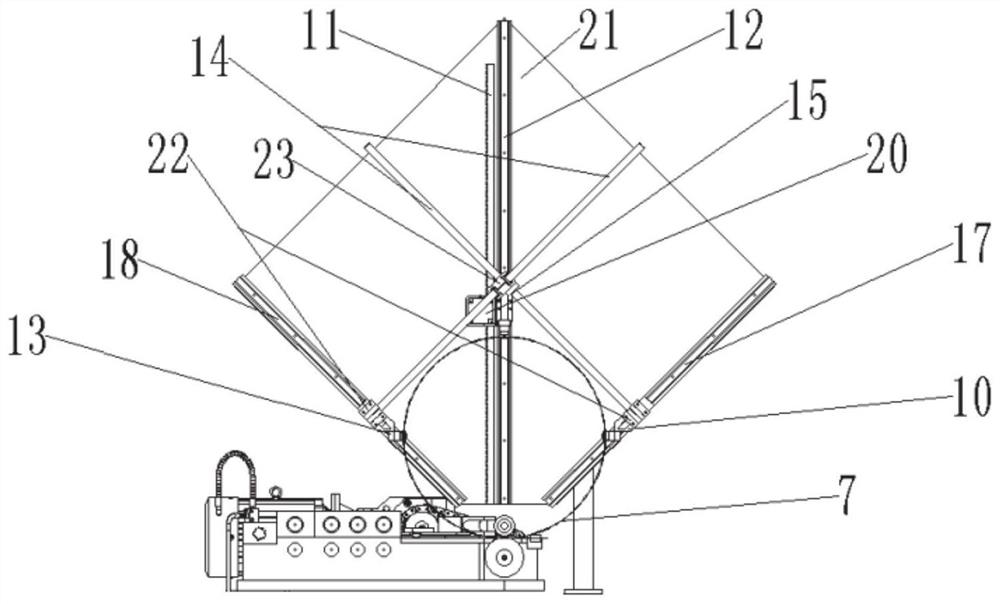

[0033] Specifically, a frame 2 is fixed on the top of the base 1 , a diameter adjusting mechanism 4 is fixed on the top of the frame 2 , and the diameter adjusting mechanism is provided with a vertically arranged first slide rail 12 and an inclined second slide rail.

[0034] Among them, there are two second slide rails, namely the right bearing slide rail 17 and the left bearing slide rail 18, the right bearing slide rail 17 and the left bearing slide rail 18 are perpendicular to each other, and the first slide rail 12 is vertically downwardly arranged on the Between the...

Embodiment 2

[0053] This embodiment provides a spiral air duct machine, which adopts the automatic adjustment device for processing parameters of the spiral air duct described in Embodiment 1. Specifically, it includes a diameter adjustment mechanism and a helix angle adjustment mechanism, and the diameter adjustment mechanism is fixedly arranged on the machine. On the frame, the frame is fixed on the base of the spiral duct machine, and the roller box and the steel belt mold are installed on the rack at the same time. The steel belt mold is fixed on the roller box. Turn to adjust the helix angle.

[0054] When producing spiral air ducts of different diameters, the steel strip mold holder needs to be loosened first for parameter adjustment. When adjusting the helix angle of the helical air duct, start the second stepper motor, and through the cooperation of the second gear and the second rack, the second stepper motor moves along the arc-shaped second rack, thereby driving the air conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com