Humidification system for fixed fuel cell power station and control method

A fuel cell and humidification system technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of inability to achieve humidification, low energy utilization, etc., to solve the problem of droplet entrainment and improve energy utilization efficiency, and the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

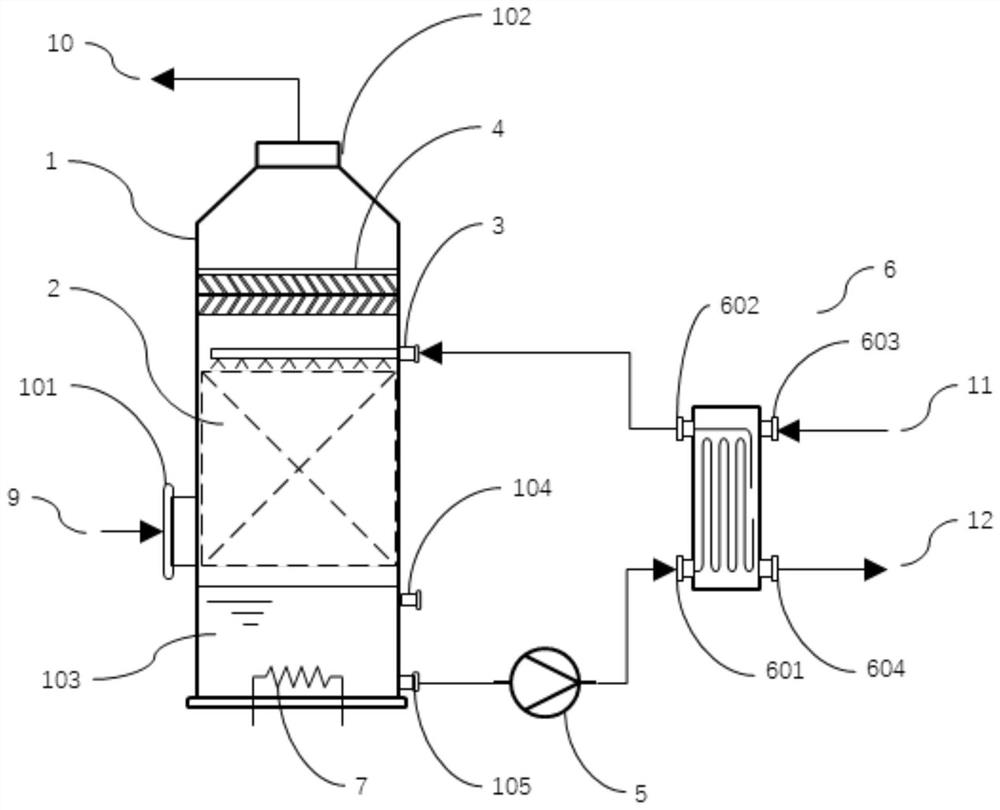

[0051] Embodiment 1: A humidification system for a stationary fuel cell power station.

[0052] Such as figure 1 As shown, the humidification system for a stationary fuel cell power station in this embodiment includes a tower body 1 . The tower body 1 has an air outlet 102 at the top and an air inlet 101 at the side. The air inlet 101 is set lower than the air outlet 102 . Between the air inlet 101 and the air outlet 102, the tower body 1 is provided with a packing layer 2, a spray device 3 and a droplet intercepting device 4 from bottom to top; the droplet intercepting device 4 is used to separate the mist entrained in the updraft droplet.

[0053] Before humidification, the reaction gas 9 enters the tower body 1 from the lower air inlet 101 and flows upward, first flows through the packing layer 2, that is, the gas-liquid contact area to complete the humidification process, and then enters the droplet interception device 4 after passing through the spray device 3, Carry ou...

Embodiment 2

[0066] Embodiment 2: A humidification system for a stationary fuel cell power station.

[0067] Such as figure 2 As shown, in this embodiment, on the basis of Embodiment 1, a second waste heat exchanger 8 is also immersed in the water storage tank 103 (only its connection interface is shown in the figure); the second waste heat exchanger 8 has a second The stack circulating water inlet 801 and the second stack circulating water outlet 802 , the second stack circulating water inlet 801 is set higher than the second circulating water outlet 802 . The second waste heat exchanger 8 and the first waste heat exchanger 6 are connected in series to the stack circulating water system of the fuel cell power plant, that is, the second stack circulating water inlet 801 is connected to the first stack circulating water outlet 604, The second stack circulating water outlet 802 and the first stack circulating water inlet 603 are connected to the stack circulating water system of the fuel c...

Embodiment 3

[0070] Embodiment 3: A control method for a humidification system for a stationary fuel cell power station.

[0071] The control method of this embodiment is used to control the humidification system for the stationary fuel cell power station of Embodiment 1, comprising steps:

[0072] S1. Turn on the electric heater 7 to the maximum power, and preheat the water in the water storage tank 103 to 60°C;

[0073] S2. Start the water pump 5, and send a message that the fuel cell power station can start running; at the same time, during the operation of the fuel cell power station, the power of the electric heater 7 is controlled by the PID controller to control the spray circulating water in the spray device 3 Water temperature, the target temperature is 60°C.

[0074] The PID controller not only controls the electric heater 7 according to the water temperature of the spraying circulating water in the spraying device 3, but also according to the changing trend of the water tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com