U-shaped ring metal sealing butterfly valve and manufacturing method thereof

A metal-sealed, U-shaped technology, applied in the lift valve, valve details, valve device and other directions, can solve the problems of affecting the sealing performance, large flow resistance, thick overall structure of the valve plate, etc., achieving high sealing level and small flow resistance area , the effect of large circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

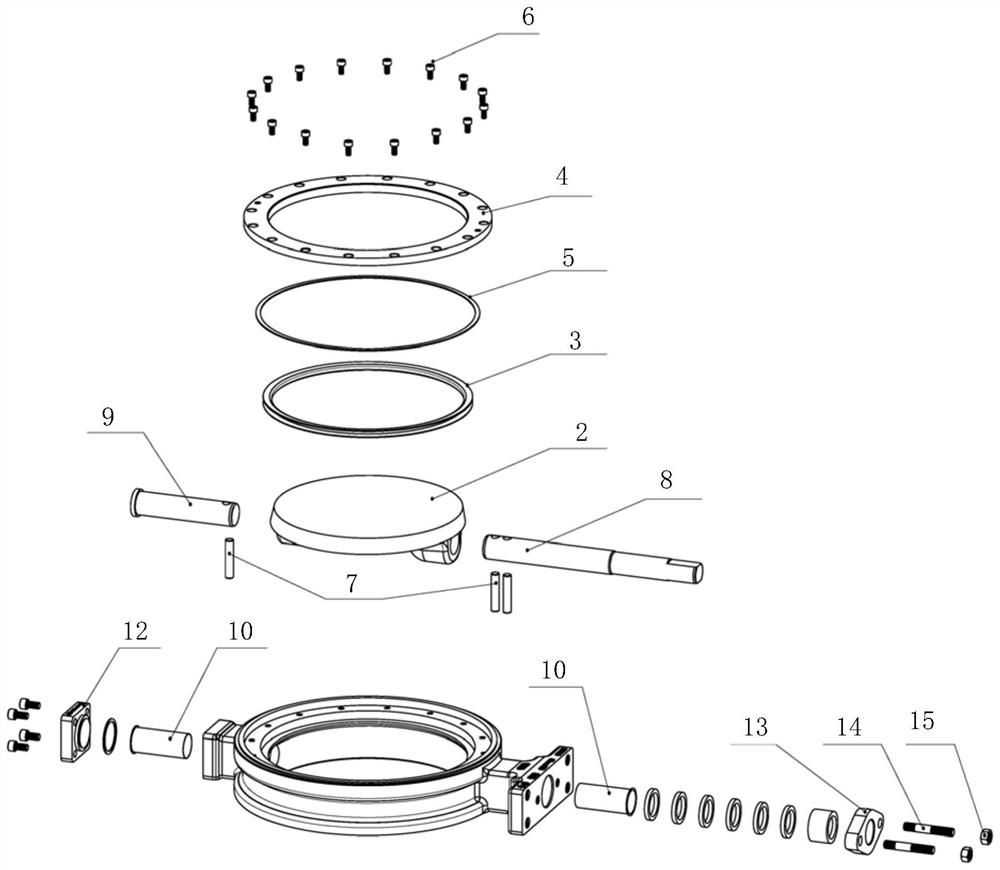

[0028] figure 1 It is an exploded schematic diagram of the structure of the U-shaped ring metal-sealed butterfly valve of the present invention.

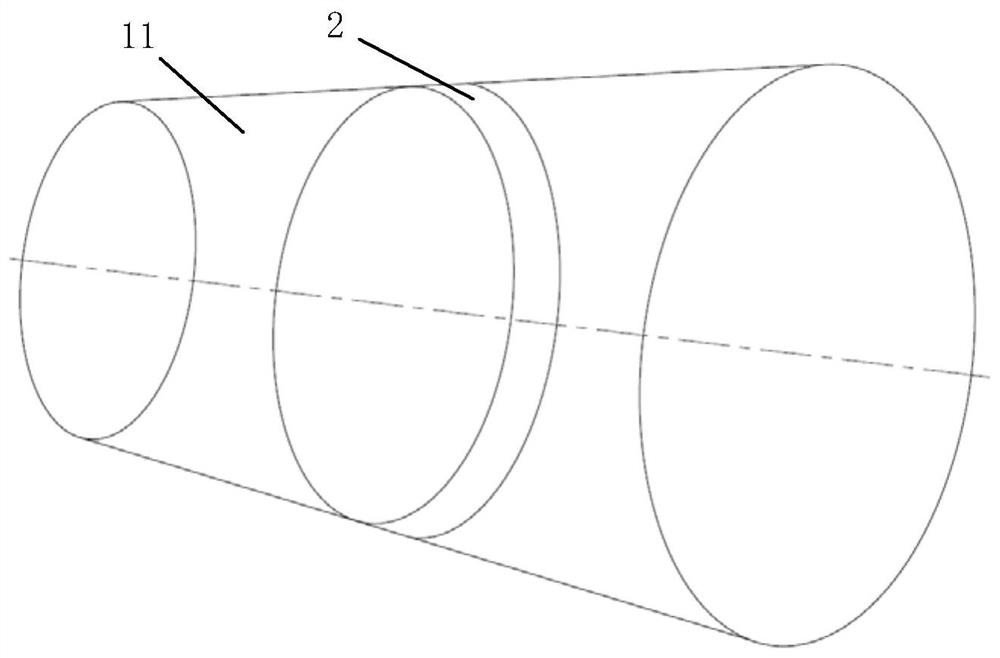

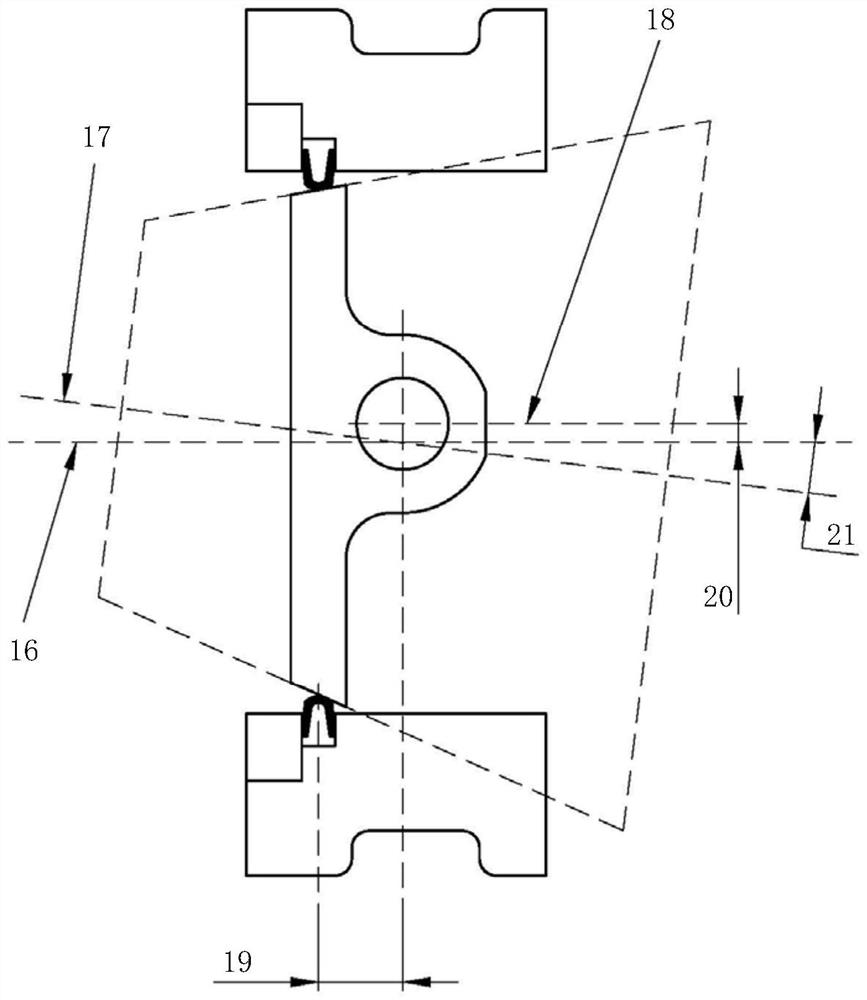

[0029] See figure 1 , the U-ring metal-sealed butterfly valve provided by the present invention includes a valve body 1, the middle of which is hollowed out and a rotatable butterfly plate 2 is installed, and a valve seat ring is arranged between the valve body 1 and the butterfly plate 2 3; wherein, the valve plate 2 is eccentrically arranged in the valve body 1, the valve seat ring 3 is a metal elastic sealing ring, and the radial section of the valve seat ring 3 is roughly U-shaped , the valve seat ring 3 forms a metal seal with the butterfly plate 2 through the radial elastic force of the U-shaped ring.

[0030] The U-ring metal-sealed butterfly valve provided by the present invention is not only a tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com