Flushing-free single-layer ceramic urinal and urine resource recycling system thereof

A ceramic body and urinal technology, applied in the field of sanitary ware, can solve the problems of increased product cost, heavy installation, and material cost, and achieve the effects of reducing the use of materials, light and easy installation, and reducing raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

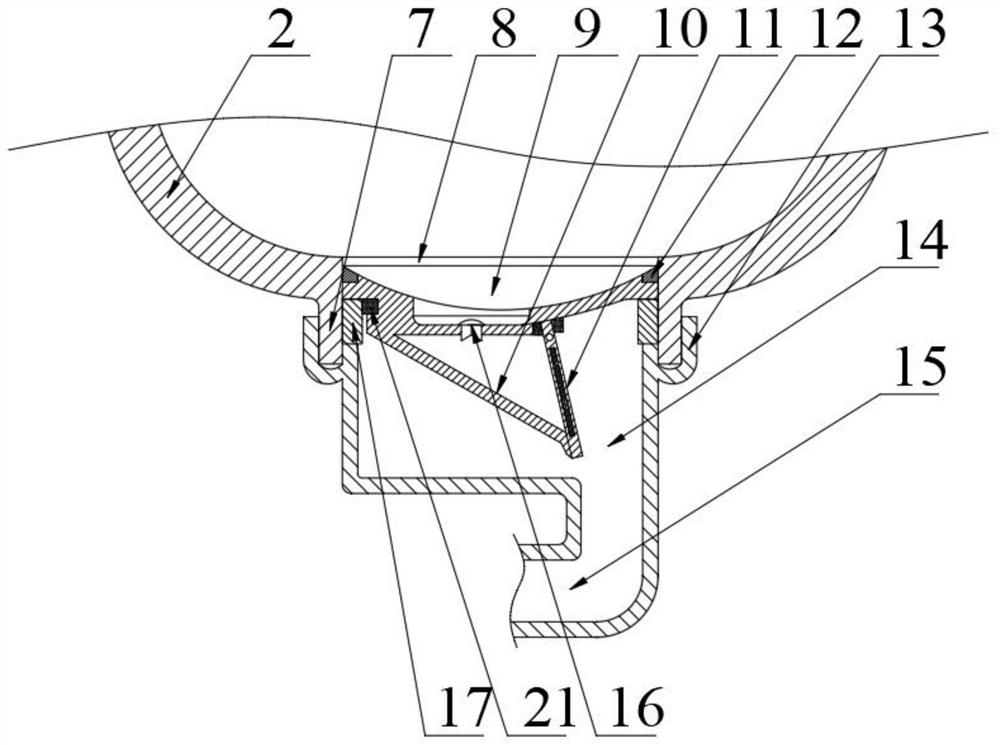

[0026] A flush-free single-layer ceramic body urinal, comprising a urinal ceramic body 2, a liquid discharge port 8 at the bottom of the urinal ceramic body is arranged eccentrically; an eccentric liquid discharge unit is axially inserted into the liquid discharge port, and the liquid discharge port The bottom is coaxially fitted with a liquid discharge cylinder 14; the eccentric liquid discharge unit includes a vertically arranged eccentric liquid discharge bowl 9 and a horizontally arranged liquid leakage cone 10, wherein the mouth of the eccentric liquid discharge bowl is upward and axially sealed and plugged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com