Apple slicing device for dried apple processing

A slicing device and apple drying technology, which is applied in metal processing, application, food processing and other directions, can solve the problems of slow efficiency, high labor intensity, finger cuts, etc., to improve the cleaning effect, reduce labor intensity, and prevent hands from being pressed effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

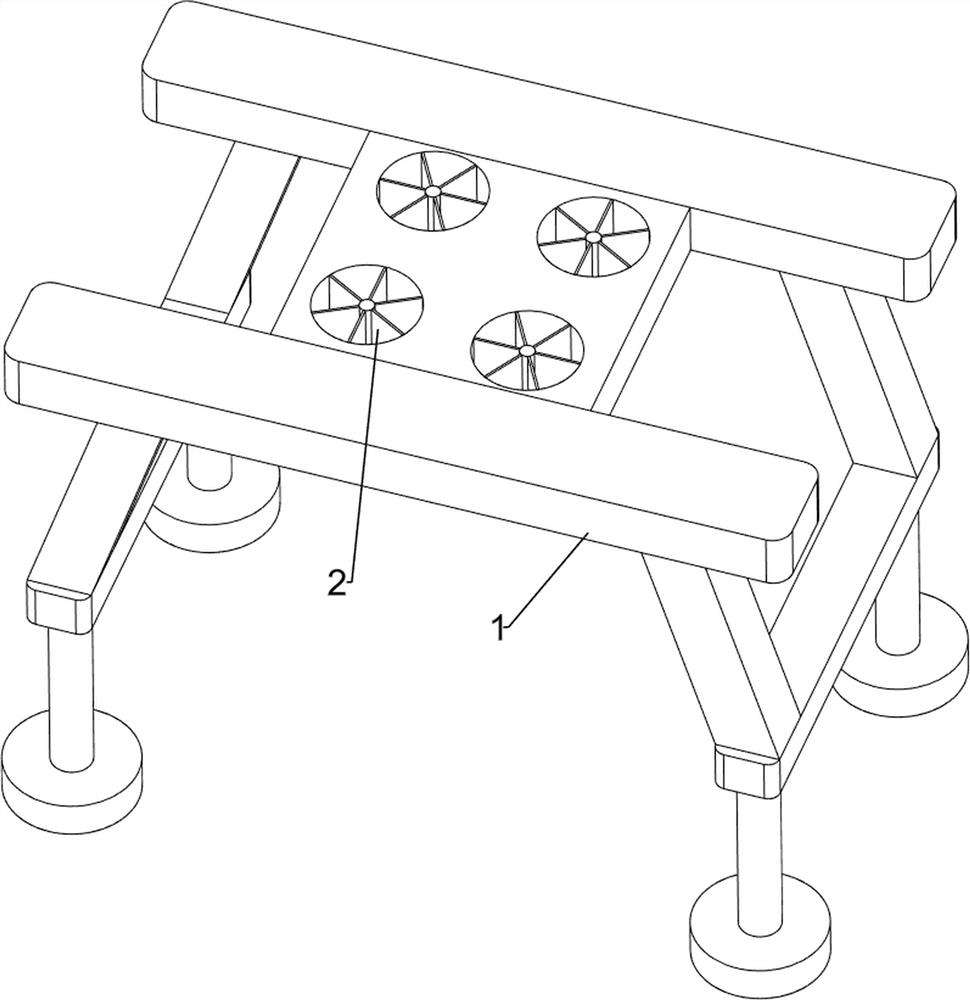

[0028] An apple slicing device for dry processing of apples, such as Figure 1-3 As shown, it includes a frame 1, a slicing knife 2, a support 3, a pressing mechanism 4 and a driving mechanism 5, four slicing knives 2 are connected in the middle of the top of the frame 1, a support 3 is connected in the middle of the top of the frame 1, and a support 3 A lower pressing mechanism 4 is installed on the top, and a drive mechanism 5 is installed between the frame 1 and the support 3. The lower pressing mechanism 4 includes a lower pressing rod 41, a contact rod 42, a support spring 43 and a lower pressing block 44, and the sliding on the bracket 3 The lower pressing rod 41 is connected with the lower pressing rod 41, the upper part of the lower pressing rod 41 is connected with the contact rod 42, the supporting spring 43 is connected between the lower pressing rod 41 and the support 3, and the lower part of the lower pressing rod 41 is connected with four lower pressing rods evenl...

Embodiment 2

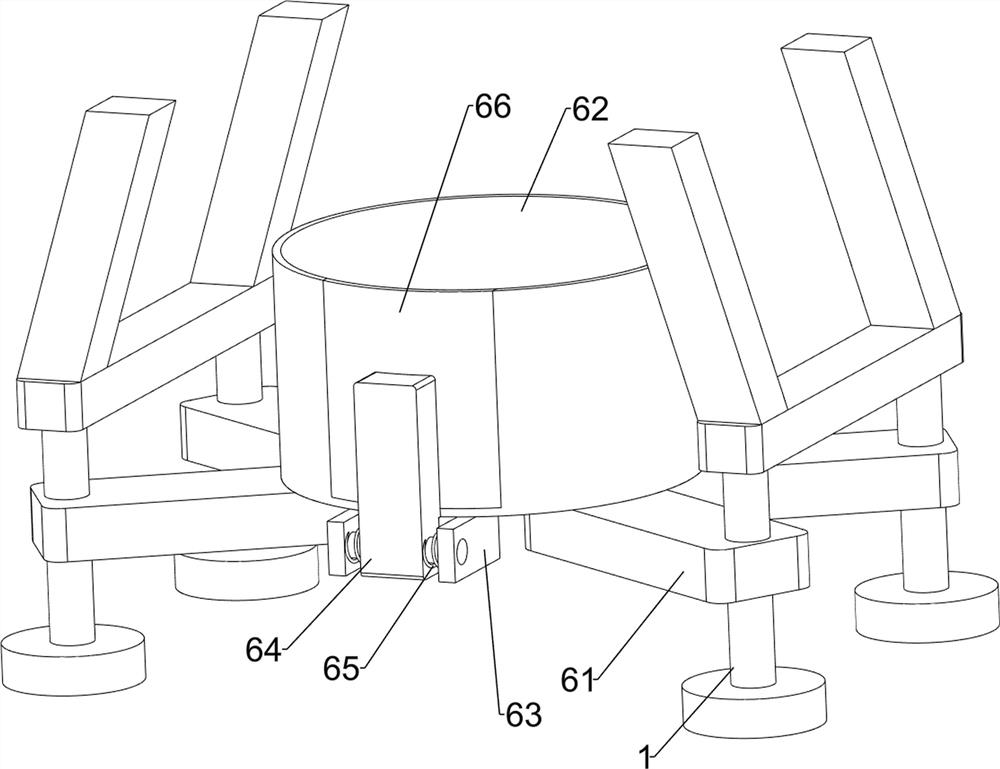

[0032] On the basis of Example 1, such as figure 1 and Figure 4 As shown, a collection mechanism 6 is also included. The collection mechanism 6 includes a support plate 61, a collection bucket 62, a connecting block 63, a swing block 64, a torsion spring 65 and a cover plate 66. The lower part of the frame 1 is symmetrically connected with four supports. Plate 61, the top of four supporting plates 61 is connected with collecting barrel 62, and the bottom rear side of collecting barrel 62 is connected with connecting block 63, and the connecting block 63 is connected with swinging block 64 in a rotatable manner, between swinging block 64 and connecting block 63 Two torsion springs 65 are connected between them, and the two torsion springs 65 are left and right symmetrical. The front side of the swing block 64 is connected with a cover plate 66, and the cover plate 66 cooperates with the collection bucket 62.

[0033] The sliced apples then fall into the collection bucket 62...

Embodiment 3

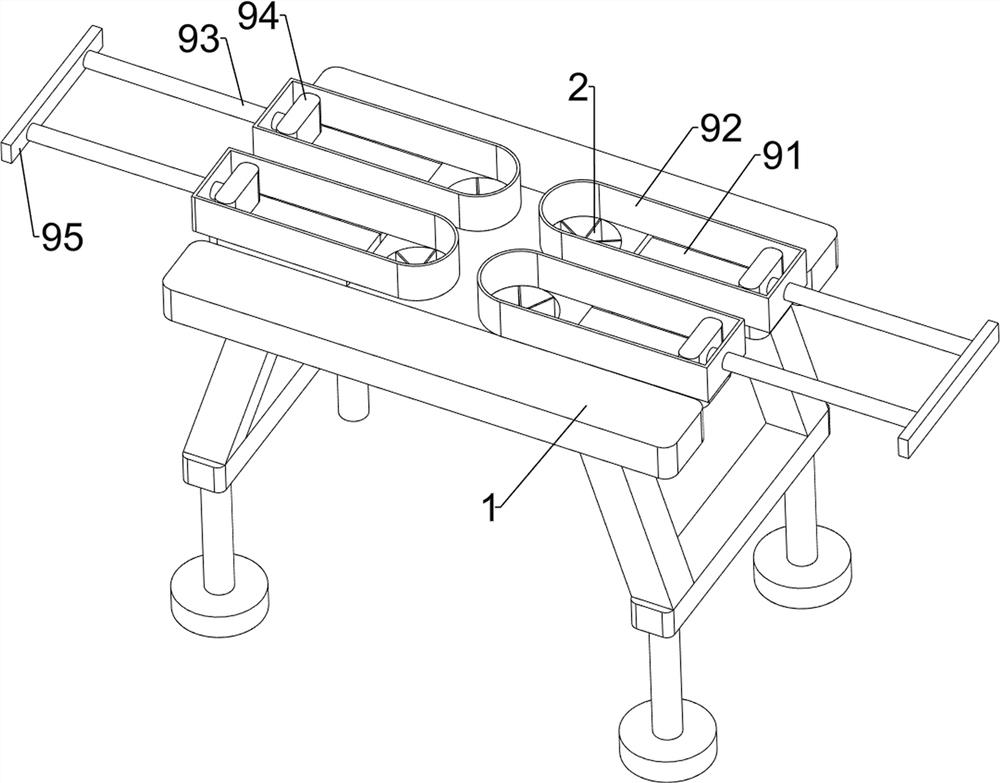

[0037] On the basis of Example 2, such as figure 1 and Figure 6 As shown, a water injection mechanism 8 is also included, and the water injection mechanism 8 includes a mounting plate 81, a water pump 82, a water inlet pipe 83 and a water outlet pipe 84. , the water pump 82 is connected with a water inlet pipe 83 and a water outlet pipe 84 respectively.

[0038] The water inlet pipe 83 can be connected to the external water pipe, and the external water pipe and the water pump 82 can be turned on, and the clear water will be sprayed out from the water outlet pipe 84 thereupon, and sprayed into the collection bucket 62, so that there is no need to manually pour the clean water into the collection bucket 62, and When clear water was sprayed into the collection bucket 62, the sliced apples in the collection bucket 62 could be sprayed, thereby further improving the cleaning effect. When no water spray was required, just close the external water pipe and the water pump 82; Clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com